Nanolipids and luminescent spheres

In the dynamic and rapidly advancing world of vaping, the pursuit of an unparalleled flavor experience is paramount. Vapers consistently seek rich, authentic, and long-lasting tastes that truly differentiate premium e-liquids. However, a significant challenge in e-liquid formulation, particularly with complex or delicate profiles, is the inherent volatility of flavor compounds. These sensitive molecules are susceptible to degradation from heat, light, oxygen, and interactions with other ingredients, leading to a diminished flavor experience, reduced shelf life, and inconsistent product quality.

This is where liposomal encapsulation emerges as a game-changer. Drawing inspiration from advanced pharmaceutical and food science, this sophisticated delivery system offers a powerful solution to protect and preserve volatile flavor compounds, ensuring that every puff delivers the intended, vibrant taste.

Flavor compounds are, by definition, volatile. This characteristic is precisely what allows them to evaporate and interact with our olfactory receptors, providing the sensation of taste and aroma. However, this same volatility makes them highly vulnerable once mixed into an e-liquid base. The primary threats include:

These challenges explain why some e-liquids lose their vibrancy quickly or deliver inconsistent flavor throughout their lifespan. Addressing these issues effectively is crucial for producing a truly premium product.

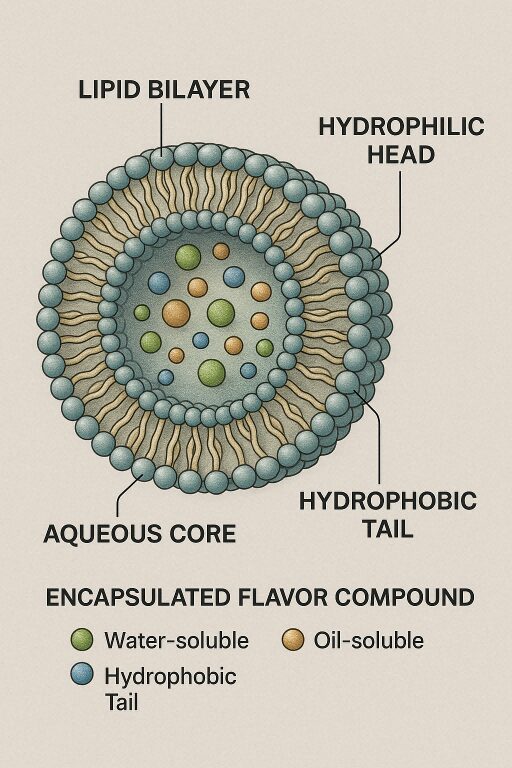

Liposomal encapsulation is a sophisticated technology that involves entrapping active compounds (in this case, flavor molecules) within microscopic spherical vesicles called liposomes. These vesicles are composed of one or more concentric lipid bilayers, structurally similar to cell membranes.

Think of a liposome as a tiny, multi-layered bubble made of fatty substances. These “bubbles” can precisely enclose and protect delicate cargo.

Liposomes are primarily formed from phospholipids, naturally occurring lipids with a unique amphiphilic structure – meaning they have both a hydrophilic (water-attracting) head and a hydrophobic (water-repelling) tail. When phospholipids are dispersed in an aqueous solution, their hydrophobic tails spontaneously arrange themselves away from the water, forming a bilayer. This bilayer then folds in on itself to create a spherical vesicle, encapsulating an aqueous core.

This versatile structure allows liposomes to effectively encapsulate a wide range of flavor molecules, regardless of their solubility characteristics.

Diagram of liposome structure

The protective power of liposomes lies in their unique barrier properties:

Implementing liposomal encapsulation in e-liquid formulation offers a host of significant benefits, elevating product quality and consumer satisfaction:

Comparison of liquid changes before and after

While the benefits of liposomal encapsulation are clear, its successful implementation in e-liquid manufacturing requires careful consideration:

The future of e-liquid formulation is moving towards increasingly sophisticated ingredient technologies. Liposomal encapsulation stands at the forefront of this evolution, offering a robust and scientifically validated approach to overcoming the inherent challenges of volatile flavor compounds. As research progresses, we can expect even more tailored and efficient liposomal systems specifically designed for the unique demands of vaping. This technology is not just about protection; it’s about unlocking the full potential of flavor.

For e-liquid manufacturers dedicated to delivering an unparalleled and consistent flavor experience, embracing advanced technologies like liposomal encapsulation is paramount. Our “CUIGUAI Flavoring” e-liquid specific flavor concentrates are developed with future-proof compatibility in mind, ensuring seamless integration with cutting-edge encapsulation methods. Partner with us to elevate your product’s stability, shelf life, and, most importantly, its flavor integrity, delivering a truly premium experience to your customers.

The shift towards scientifically advanced flavor protection mechanisms marks a significant leap forward in the e-liquid industry. By leveraging the power of liposomal encapsulation, manufacturers can ensure their products consistently deliver the vibrant, authentic, and long-lasting flavor profiles that discerning vapers demand, cementing their reputation for quality and innovation.

CUIGUAI Flavoring Close-up of e-liquid concentrate bottle

Keyword:liposomal vape flavor,e-liquid flavor stability,flavor encapsulation vape,liposomal e-liquid,protected flavor compounds,e-liquid formulation technology,advanced flavor delivery vape,shelf life e-liquid flavor,

consistent vape flavor,liposome technology e-liquid,flavor preservation vaping,premium e-liquid flavor,flavor compound oxidation,

thermal degradation e-liquid,photodegradation vape juice,phospholipids e-liquid,controlled flavor release vape,e-juice flavor innovation

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jul 18, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy