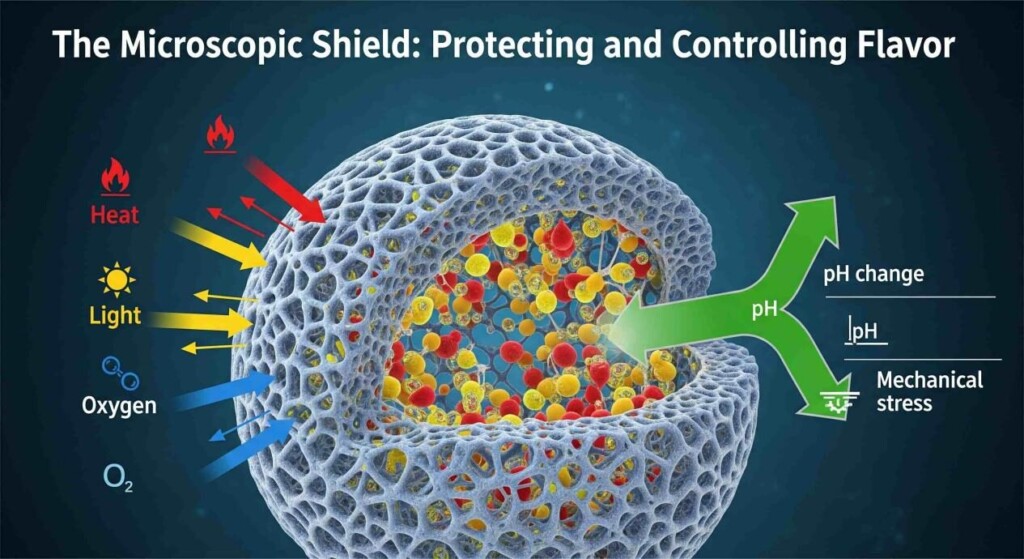

The Microscopic Shield: Protecting and Controlling Flavor

In the global market for consumer products, flavor is king. It is the primary driver of repeat purchases, brand loyalty, and overall product satisfaction. Yet, the very molecules that create these captivating aromas are often fragile and fleeting. Aroma compounds are inherently volatile, prone to oxidation, and highly susceptible to degradation from external stressors like heat, light, and moisture. This inherent instability leads to a silent but pervasive problem: a gradual loss of flavor potency over a product’s shelf-life, resulting in a diminished consumer experience and significant brand erosion.

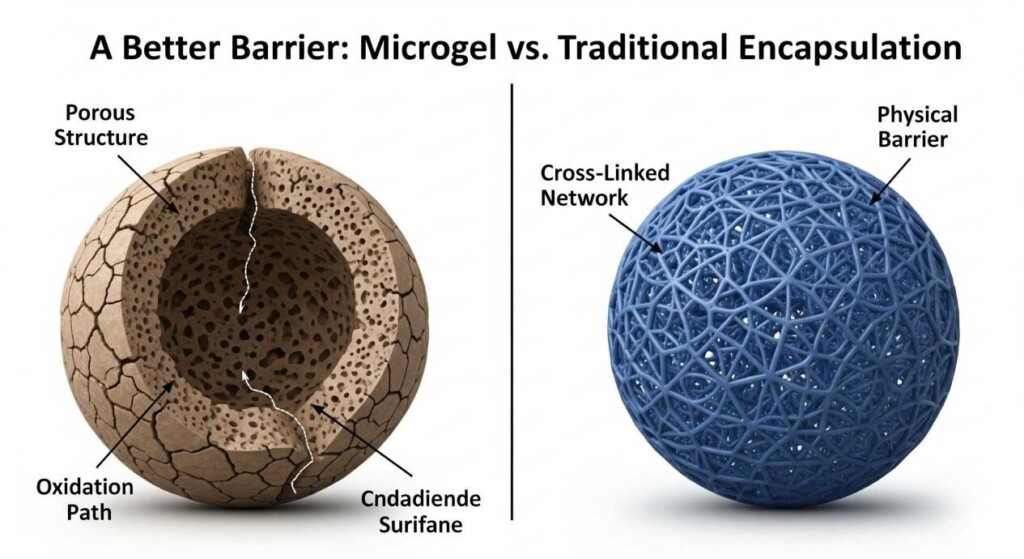

For decades, the industry has relied on traditional methods of flavor protection, such as simple emulsification and spray drying. While effective to a degree, these techniques often fall short of providing the complete, long-term stability required in today’s demanding market.

A new era of flavor technology has dawned with the advent of aroma encapsulation using edible microgels. This technology represents a paradigm shift from passive preservation to an active, intelligent flavor management system. By creating a microscopic, porous network around delicate aroma molecules, microgels offer a pathway to protect flavor integrity, extend shelf-life, and even enable a new level of controlled flavor release for a more dynamic and engaging sensory experience. This comprehensive technical guide will delve into the science behind this transformative technology, explore its practical applications, and analyze its profound implications for the future of the flavor industry.

To understand the power of microgel encapsulation, we must first appreciate the inherent vulnerabilities of the molecules we are trying to protect.

Aroma compounds, by their very nature, are small, light molecules with a low boiling point. This is what allows them to easily vaporize and travel to our olfactory receptors. However, this same property makes them highly susceptible to passive loss over time. In a product, these molecules can slowly evaporate or diffuse out of the matrix, leading to a gradual but irreversible decline in flavor intensity. This is a primary cause of products tasting “flat” or “faded” after a few months on the shelf.

Many of the most desirable aroma compounds, particularly those responsible for fresh, fruity, and green notes, are chemically unstable. They contain unsaturated bonds that are highly reactive with oxygen. This reaction, known as oxidation, can lead to the formation of aldehydes and ketones, which produce stale, rancid, or metallic off-notes. This is a catastrophic failure that can completely ruin a product’s flavor profile.

The environment is a constant threat to flavor integrity.

Traditional methods like simple emulsification or spray drying often fail to provide a complete barrier against all these stressors. While a well-formed emulsion can protect against water, it offers little to no protection against oxygen. Similarly, a spray-dried powder can protect against volatility, but the porous nature of the carrier can still allow oxygen to penetrate and cause oxidation. A 2023 study in Food Hydrocolloids highlighted the limitations of these methods and emphasized the need for more robust, multi-layered encapsulation systems to address these challenges (Reference 1: Food Hydrocoll., 2023, “Advances in Microencapsulation for Flavor Protection”).

A microgel is a microscopic, cross-linked polymer network, typically with a high water content. Unlike a simple coating, a microgel forms a robust, three-dimensional structure that provides a powerful physical and chemical barrier against external stressors.

The process of aroma encapsulation with microgels involves trapping the flavor molecules within the porous structure of the gel matrix.

The choice of material for the microgel is critical and depends on the specific flavor, the desired release profile, and the final product application.

It’s important to distinguish between a bulk hydrogel and a microgel. A hydrogel is a large, macroscopic gel, while a microgel is a microscopic particle of that same gel. The process of creating the microgel particle is the key to creating a stable, easy-to-use powder.

The Flavor and Extract Manufacturers Association (FEMA) has established a comprehensive list of safe, food-grade hydrocolloids and other ingredients that can be used for encapsulation, ensuring that all materials are safe for consumption (Reference 2: FEMA, 2024, “Safety and Quality Guidelines for Flavoring Substances”).

Creating an aroma-encapsulated microgel is a sophisticated, multi-step process that requires precise control over both chemistry and engineering.

The first step is to create a stable oil-in-water emulsion of the flavor compound within the gelling polymer solution. This is typically done using a high-shear mixer to create small, uniform oil droplets, each destined to become a core within the microgel.

This is the most critical step, where the liquid emulsion is converted into solid microgel particles.

After gelation, the wet microgels are converted into a stable powder for long-term storage and easy integration into final products. This is typically done through freeze-drying (which preserves the porous structure) or spray drying (a more cost-effective, scalable method).

The success of the encapsulation process depends on the precise control of variables like:

A Better Barrier: Microgel vs. Traditional Encapsulation

The adoption of microgel encapsulation is not just a technical upgrade; it is a strategic business decision that provides a powerful competitive edge.

By creating a robust, cross-linked barrier, microgels provide a superior level of protection against all three major forms of degradation.

This is perhaps the most innovative aspect of microgel technology. By engineering the properties of the gel, we can control when and how the flavor is released.

In a market where consumers are increasingly scrutinizing ingredient lists, edible microgels have a significant advantage.

Microgel encapsulation can also be used to mask or reduce the perception of off-notes from other ingredients, such as bitterness from nicotine or certain flavor compounds. By physically separating the off-note from the taste receptors, the microgel can improve the overall palatability of the final product.

The transition to microgel encapsulation is a major investment, and its success must be proven through rigorous analytical validation.

To prove the controlled-release functionality, we conduct a series of tests to measure the rate and extent of flavor release over time and in response to various triggers. This can be done using a simulated oral or thermal environment to mimic the conditions of consumption or vaporization.

While the cost of microgel encapsulation is higher than traditional methods, the long-term benefits far outweigh the initial investment.

The Promise of Precision: The Taste of Excellence

Aroma encapsulation using edible microgels is not just a technological curiosity; it is a fundamental shift in how we approach the creation of flavor. It is a transition from an era of passive flavor preservation to a new era of active, intelligent flavor management.

By embracing this technology, flavor companies can ensure their products meet the highest standards of purity and consistency, while also delivering a superior and more engaging sensory experience. For a consumer, this means a product that tastes as fresh on the last day of its shelf-life as it did on the first. For a brand, it means a powerful competitive advantage and a foundation for long-term growth. The future of flavor is here, and it is meticulously shielded within a microscopic gel.

Keywords: vape microgel encapsulation, aroma protection technique

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Sep 18, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy