Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 18, 2025

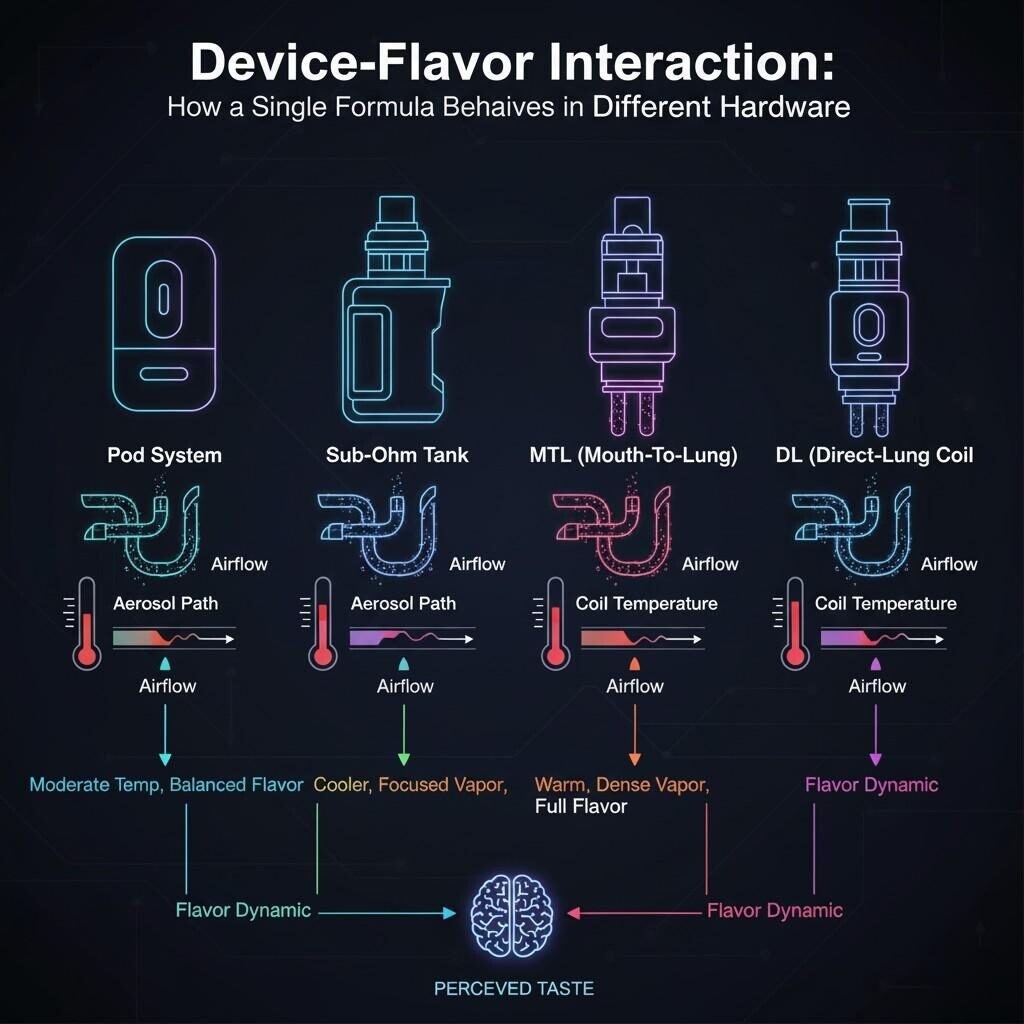

Device-Flavor Interaction Diagram

As a flavor manufacturer in the e-liquid industry, you may sometimes hear feedback like: “Your mango flavor tastes so good in Pod A, but flatter or more metallic in Device B.” Why does a carefully developed flavor formula, which performs well in one device, fail or change character in another?

This phenomenon is not anecdotal — it arises from a constellation of physical, chemical, and thermal factors that govern how flavor molecules are volatilized, delivered, and perceived. In other words: the device matters—even for the same base formula.

In this blog post, we dissect the key reasons why the same flavor formula may taste different across devices. We will cover:

By the end, your R&D team will have a robust conceptual framework to anticipate, diagnose, and optimize flavor performance across multiple devices.

Let’s begin by understanding the fundamental thermodynamic and aerosol principles at play.

To understand why flavor differs across devices, we must first revisit how flavor compounds transition from liquid to aerosol, and how device constraints shape that process.

Flavor molecules in an e-liquid must transition from the liquid phase into the gas or aerosol phase. The vapor pressure (or volatility) of each compound governs how readily it volatilizes under a given temperature. Compounds with higher vapor pressures are more readily drawn into vapor, whereas low-volatility compounds require more energy (heat) or longer dwell time.

In a given device, the coil temperature, dwell time, airflow, and saturation influence how much of each flavor molecule goes into the vapor. If the device under-heats, less of low-volatility compounds are delivered; if it overheats, some compounds may degrade or overshoot their ideal volatilization point.

Additionally, Raoult’s law and deviations therefrom (activity coefficients) mean that in mixtures, partial vapor pressures are influenced by interactions among flavor, nicotine, and solvents (PG/VG). In some devices, non-ideal mixing leads to selective evaporation, causing differences in flavor ratios from the original formula.

A recent study using holographic microscopy and deep learning showed that flavoring additives decrease the volatility of e-cig aerosols, and that the negative correlation between VG content and volatility holds, meaning devices that favor more dense vapor may suppress flavor volatility. arXiv

Not all flavor molecules venture as free vapor; many become encapsulated in aerosol droplets. The droplet size distribution plays a critical role in:

Different devices produce different aerosol droplet size spectra, which changes flavor perception. Devices with higher coil power or more aggressive airflow may produce finer droplets (or more vapor dilution), shifting the balance between gas-phase aroma molecules and droplet-borne flavor.

Moreover, the droplet’s residence time, evaporation kinetics, and boundary-layer diffusion all influence how much flavor is delivered before inhalation or deposition.

Thus, when you move a flavor formula from Device A to Device B, the aerosol’s droplet spectrum and transport dynamics change, altering the effective flavor intensity and balance.

Within the device, temperature is not uniform. Microzones near the coil may reach higher temperatures than the bulk liquid or vapor path, leading to localized heating and nonlinear volatilization of flavor compounds.

These temperature gradients produce boundary layers around coil surfaces, in which vapor concentration, temperature, and flow velocity differ from the mean. In high-draw devices, convective flow may erode boundary layers (leading to efficient flavor transfer); in tight-draw devices, boundary layers may trap heavier molecules or slow diffusion.

Hence, the same formula in Device A (with aggressive convection) might flush heavier flavors, but in Device B (low airflow), boundary retention or flavor “drag” may reduce or skew flavor output.

Having covered foundational principles, now let’s explore how specific device parameters influence flavor delivery and why the same formula might behave differently across hardware.

All these device and operational variables can individually and synergistically change flavor delivery from the same formula.

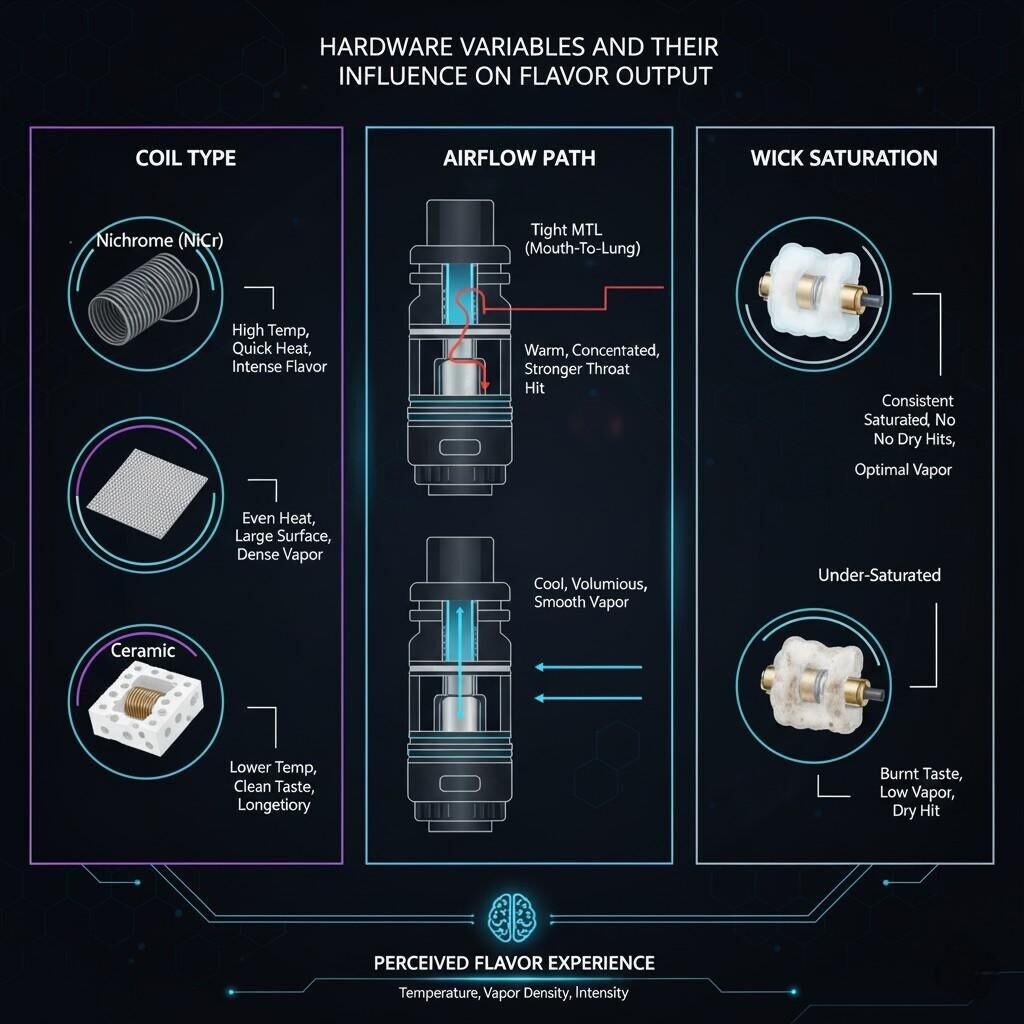

Hardware Variables Flavor Influence

Even if hardware were perfect, chemical and thermal dynamics differ across devices—leading to perceptual differences.

Under harsher devices (higher wattage or poor wicking), flavor compounds may partially degrade to secondary species (aldehydes, ketones, oxidation fragments). These byproducts may add subtle “off notes” or increase irritancy.

For instance, some studies have shown that cinnamaldehyde-containing e-liquids produce more formaldehyde or acetaldehyde under higher thermal stress. PMC+1

Thus, in one device, your flavor remains pure; in another, mild decomposition products sneak in, altering the taste.

Some flavor molecules (especially heavier ones) may adsorb onto coil surfaces, wick material, or device internals under certain conditions. In circuits or temperature regimes with recurrent heating and cooling, molecules may condense on surfaces and later be released, causing “ghost flavors” or muted intensity.

Device A may drive less adsorption (hotter, continuous flow), while Device B may encourage more adsorption/condensation cycles and thus “loss” of flavor molecules.

As mentioned before, in multicomponent mixtures, the evaporation process may not faithfully reflect the liquid-phase ratio. Differences in activity coefficients, molecular interactions, and volatility give rise to fractional evaporation or preferential evaporation of certain molecules under particular thermal or flow conditions.

A new mechanistic insight from a study on non-selective evaporation in porous atomizers suggests that the evaporation layer concept, where the gas-phase composition matches that of the transferred liquid layer, can deviate from the simple bubble-point model.

Thus, Device A and Device B, with different capillary or wick constraints, may yield different relative flavor concentrations in vapor.

PG and VG themselves interact dynamically with flavor molecules under device conditions.

Therefore, a formula that tastes perfect in a “gentle” device may be influenced by solvent stress in a more aggressive device.

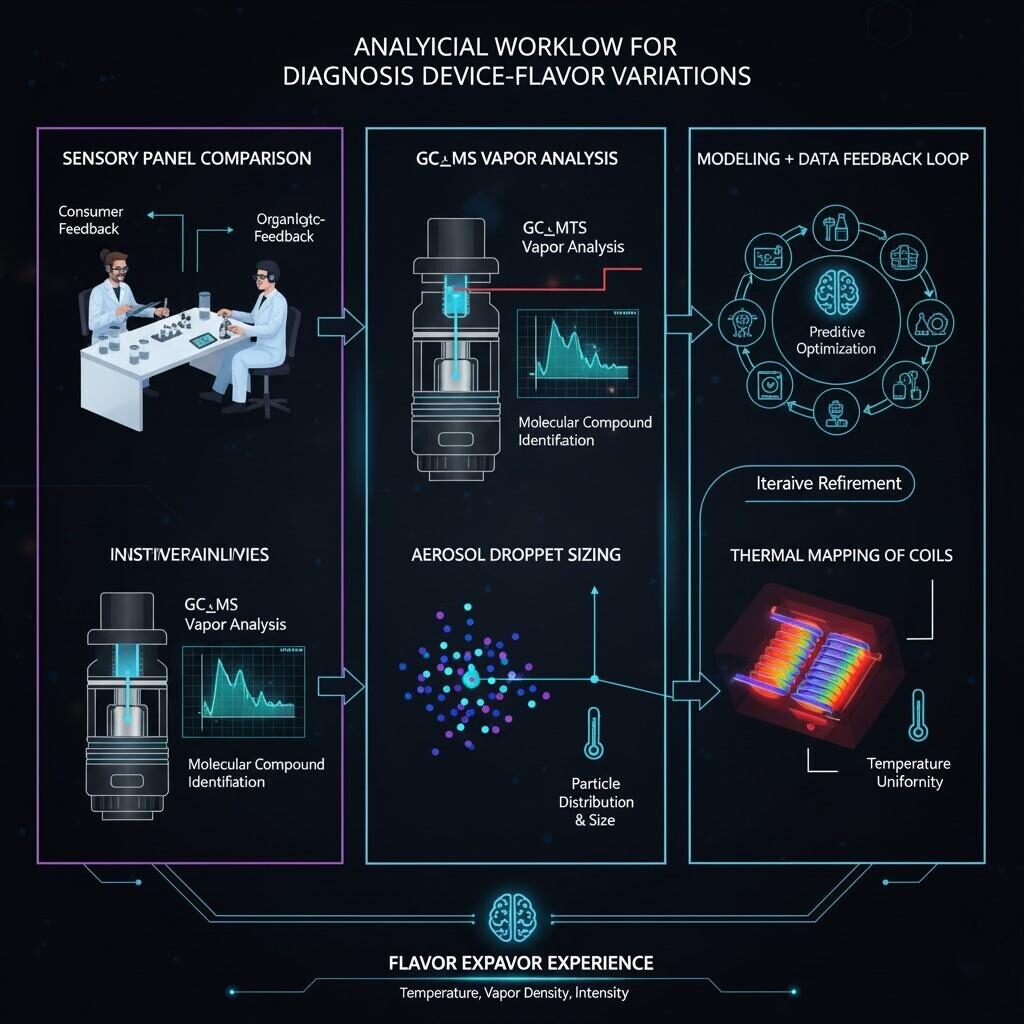

To manage and optimize across devices, you need a structured diagnostic workflow. Below is a recommended approach.

This quickly highlights which devices cause significant perceptual shifts.

If a flavor compound is present in liquid but underrepresented in a device’s vapor, that suggests poor volatilization, condensation, or adsorption losses.

Device-to-device differences in droplet size lead directly to perceptual differences.

Combining thermal map with flavor output helps link performance to thermal stress zones.

Over iterations, you can build a device-performance correction factor library to predict how your formula might shift in new hardware.

Device-Flavor Diagnostic Workflow

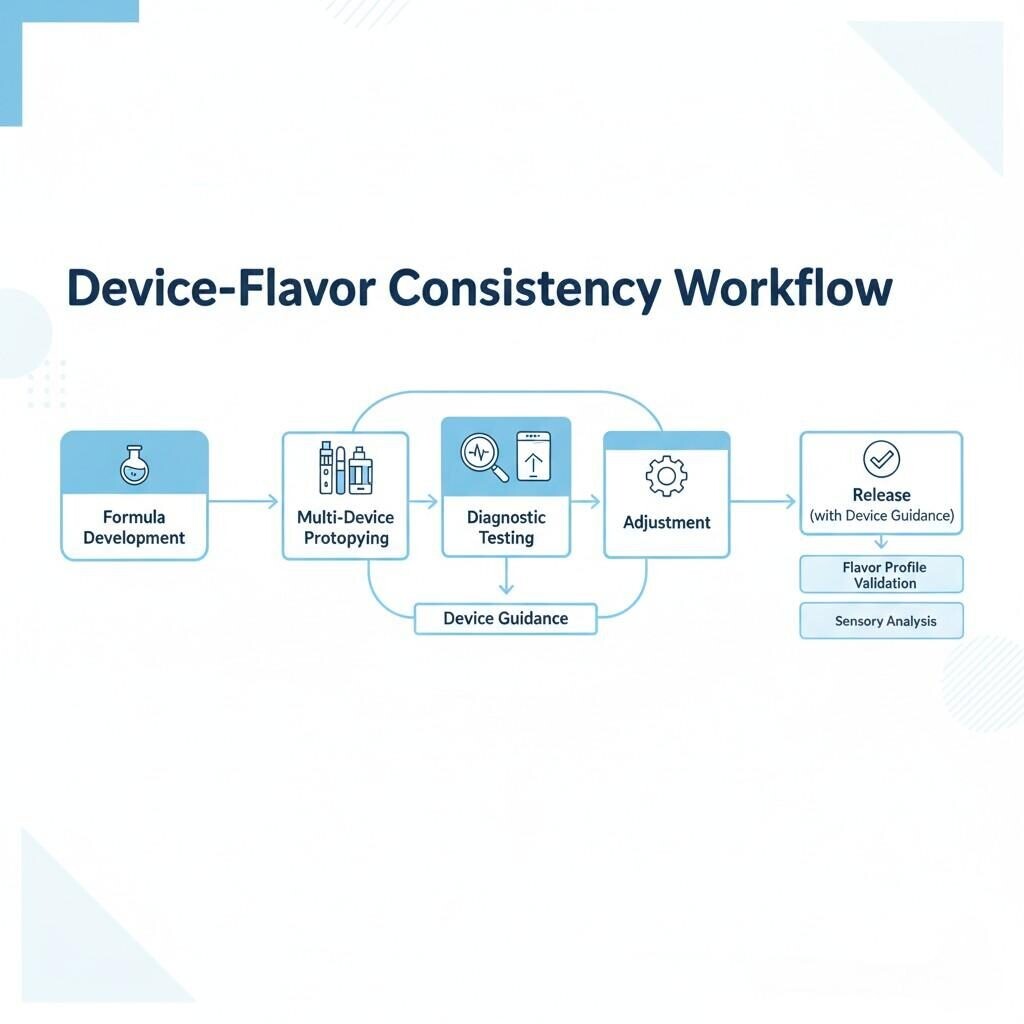

Given the multiple variables above, what can flavor developers do to ensure consistency across different devices? Here are key strategies and best practices.

From the outset, design your formula to perform acceptably even under less ideal devices. That means:

Create a volatility-graded flavor stack: combine fast-volatility top notes, mid-volatility body notes, and lower-volatility anchoring notes. That way:

From early stages, test your formula in a range of representative devices (e.g. pod, MTL, sub-ohm, high-wattage). Identify divergence early and adjust formula “correction factors” for each device type.

Where variation is unavoidable, consider shipping device-optimized variants of your flavor formula—slightly rebalanced for low-power pods vs high-power sub-ohm. That can ensure best-in-class performance per device class.

Supply your customers (device integrators or e-liquid formulators) with guidance: ideal coil resistance, wattage range, airflow needs, or maximum draw duration to preserve flavor integrity.

By integrating these strategies, you shift from making flavors for a “reference device” toward building flavors resilient across a device ecosystem.

Below are hypothetical or illustrative cases based on typical flavor development challenges.

Your tropical fruit flavor includes esters (ethyl butyrate, ethyl hexanoate) and heavier lactones. In a low-power MTL pod (12 W, tight draw, short chimney), you find the flavor is muted and “top-note heavy.” In a sub-ohm tank (30 W, open airflow), the flavor is vivid but the mid-notes (lactones) are overwhelmed or slightly burnt.

Diagnosis & solution:

A creamy dessert formula uses vanillin, ethyl maltol, and buttery esters. In a ceramic pod (lower power, slower heat-up), the vanilla is rounded and smooth. In a mesh rebuildable (fast heating, high airflow), the buttery esters “pop” initially but develop a metallic edge mid-session due to slight oxidation.

Diagnosis & solution:

A low-level menthol additive helps smoothness in pods. In mod usage, users detect a slight mint scratchiness. The aggressive airflow and higher temperature amplify menthol’s cooling edge disproportionately.

Diagnosis & solution:

Designing flavors that perform acceptably across devices involves navigating trade-offs.

Trying to optimize for every device may dilute peak performance. You may need to accept device-class variants rather than a perfect universal formula.

Adding more co-solvents, modifiers, or encapsulation increases formulation complexity and stability risks. Always validate shelf life, chemical stability, and compatibility.

Formulas pushed heavily may produce unseen degradation or harmful byproducts in aggressive devices. Always include a safety margin in concentration, avoid borderline compounds, and perform stress testing.

Users may adapt to a particular device’s flavor over time, masking small differences. But initial impressions and first puffs influence perception and brand reputation—so cross-device consistency remains critical.

New device architectures, temperature-control algorithms, or coil technologies (e.g. ceramic, mesh, temperature-feedback) may shift performance. Keep your flavor pipeline agile and adaptable.

In sum, the same flavor formula tastes different across devices because of the interplay of:

To manage this, a flavor R&D teams should:

By embracing these strategies, your flavor portfolio can deliver consistent, high-fidelity taste across a wide hardware ecosystem, reducing user complaints and boosting product adoption.

Device-Flavor Consistency Workflow

Are you grappling with cross-device flavor inconsistency or want to co-develop device-resilient flavor variants?

We invite you to request free sample sets optimized for multiple device classes or engage in technical exchange with our formulation team. Let’s collaborate to make your flavors truly fly—across every device.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.com】

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy