Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

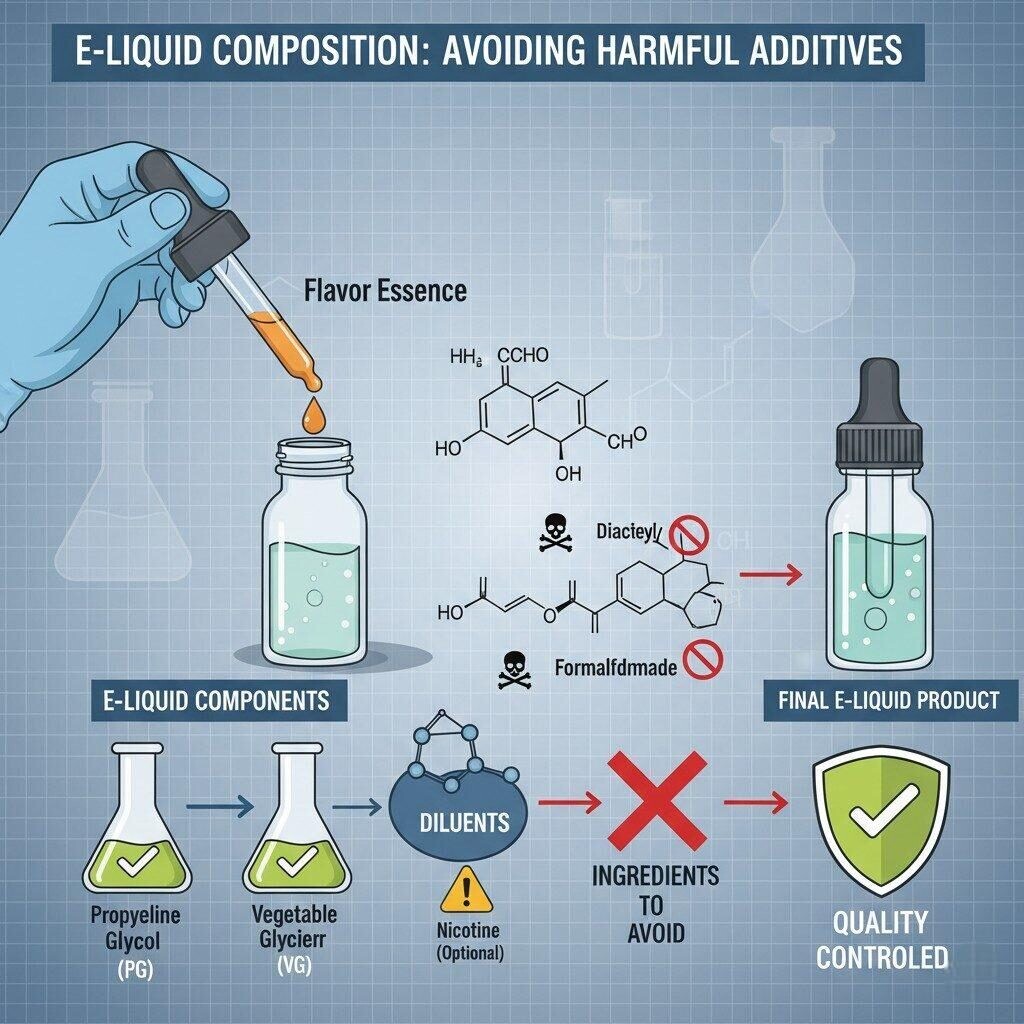

E-Liquid Composition: Avoiding Harmful Additives

The flavor industry has played a transformative role in shaping the vaping experience, turning e-liquids from simple nicotine carriers into complex, sensory-rich formulations. From fruit blends to dessert profiles and beverage-inspired aromas, flavors define the identity of every vape product.

However, as the industry matures and global regulatory frameworks tighten, flavor safety has become the defining factor of product quality. The chemical composition of flavoring ingredients directly impacts toxicological safety, thermal stability, and consumer health outcomes.

This blog post provides a technical, evidence-based overview of flavor ingredients that should be avoided in e-liquids — not just for regulatory compliance, but for responsible formulation and brand integrity.

Whether you are a formulation chemist, product developer, or brand owner, this guide serves as a practical roadmap for developing compliant and safe vape flavors in the modern global market.

Flavor compounds used in food or cosmetics are not automatically safe for inhalation. The respiratory route introduces compounds directly into lung tissues, bypassing the metabolic filtration of the digestive system. This fundamental difference forms the scientific basis for vape-specific flavor safety evaluation.

Different regions regulate vaping flavors under distinct frameworks:

According to the U.S. National Institutes of Health (NIH), many flavoring substances recognized as safe for ingestion may generate reactive or toxic by-products under vaporization conditions [¹].

The FDA’s “GRAS” (Generally Recognized As Safe) list applies only to oral consumption, not inhalation. While compounds like vanillin, ethyl maltol, and limonene are safe to eat, they may undergo thermal degradation during vaping, producing irritants or aldehydes.

Therefore, professional e-liquid flavor formulation must go beyond GRAS status — it must include inhalation toxicology and vapor-phase stability testing.

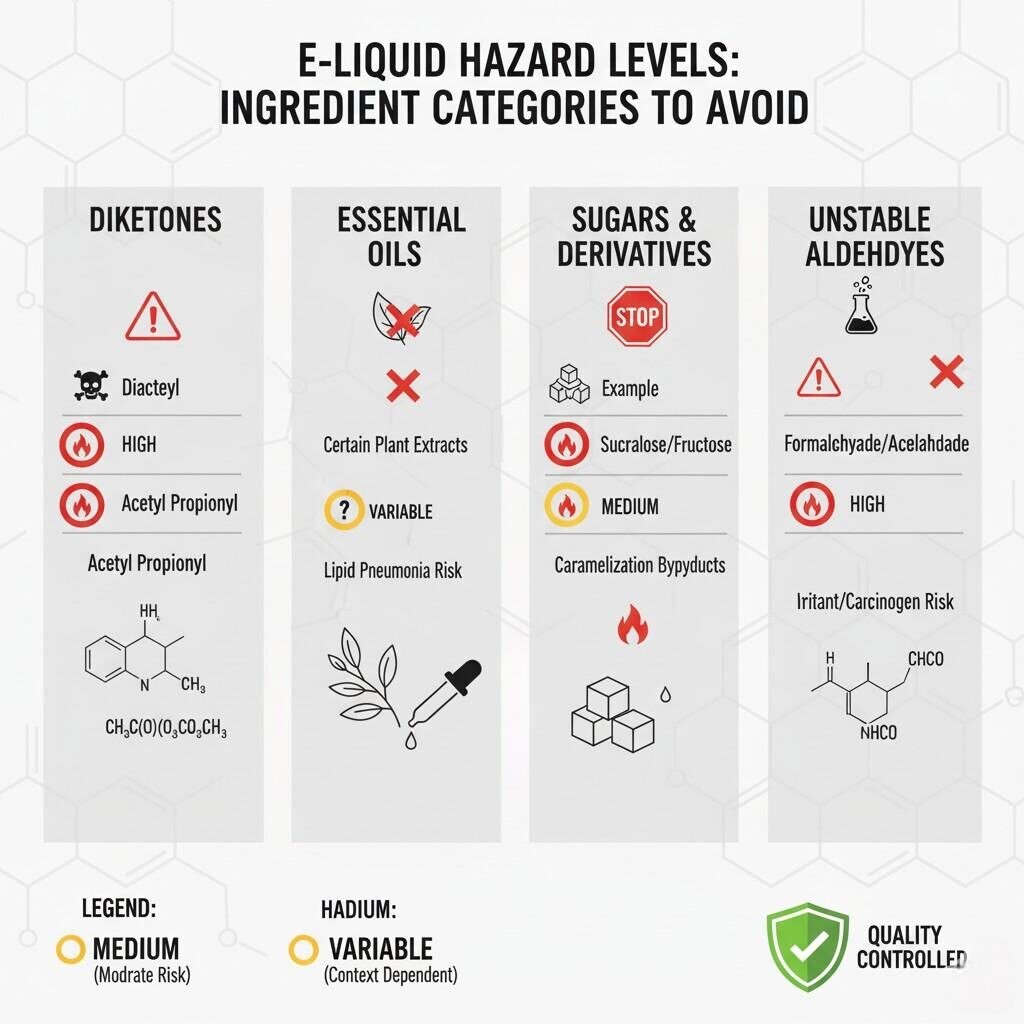

E-Liquid Hazard Levels: Ingredient Categories to Avoid

Chemical Family: α-diketones

Common Use: Butter, cream, and caramel notes

Diketones such as diacetyl (2,3-butanedione) and acetyl propionyl (2,3-pentanedione) are widely used in food flavoring for their rich, buttery mouthfeel. However, when inhaled, these compounds have been linked to bronchiolitis obliterans, also known as “popcorn lung”, a severe respiratory disease first identified among microwave popcorn factory workers.

According to the Centers for Disease Control and Prevention (CDC), inhalation exposure to diacetyl can cause irreversible airway obstruction and chronic lung inflammation [²].

Avoid or strictly control:

Safer alternatives:

Common Use: Mint, citrus, herbal, floral, and spicy notes

While natural essential oils are popular for their authenticity and perceived “clean label” status, many of them contain volatile terpenes, ketones, or phenolic compounds that become respiratory irritants when vaporized.

Problematic examples include:

The American Lung Association advises against the use of essential oils in e-liquids due to their unpredictable combustion behavior and potential to form formaldehyde-like degradation products [³].

Best practice:

Use purified aroma isolates or synthetic analogs that mimic the sensory characteristics without introducing volatile allergens or oxidation risk.

Sugars and sweeteners can cause thermal degradation, producing carbonyls and polycyclic compounds under coil temperatures.

Avoid the following:

The European Chemicals Agency (ECHA) notes that carbonyl compounds such as acetaldehyde and acrolein are recognized respiratory irritants and should be minimized in vapor products [⁴].

Safer alternatives:

Aldehydes are essential to flavor chemistry, yet certain volatile aldehydes (such as benzaldehyde, cinnamaldehyde, and citral) are prone to oxidation or reaction with propylene glycol, forming irritant by-products.

Phenolic derivatives, including vanillin and eugenol, can undergo polymerization, affecting both safety and flavor consistency.

To maintain safety and product uniformity:

Although bright colors are appealing in beverages and candies, they are not recommended for inhalation. Many food dyes such as FD&C Blue No.1, Red No.40, or Tartrazine are not approved for vaporization use.

Inhaling particulate or aerosolized pigment residues can cause pulmonary irritation or allergic responses. Moreover, colorants can catalyze unwanted oxidation reactions in e-liquid bases.

Recommendation:

Oil-based flavor components, such as nut extracts, olive oil, or coconut oil, are strictly contraindicated in e-liquids.

Inhaled lipids may lead to lipoid pneumonia, a serious condition where fats accumulate in lung tissues, interfering with gas exchange.

As documented by the World Health Organization (WHO), lipid inhalation hazards are well-established and incompatible with vapor products intended for human use [⁵].

Solution:

Use PG-based or triacetin-based flavor carriers for full solubility and inhalation safety.

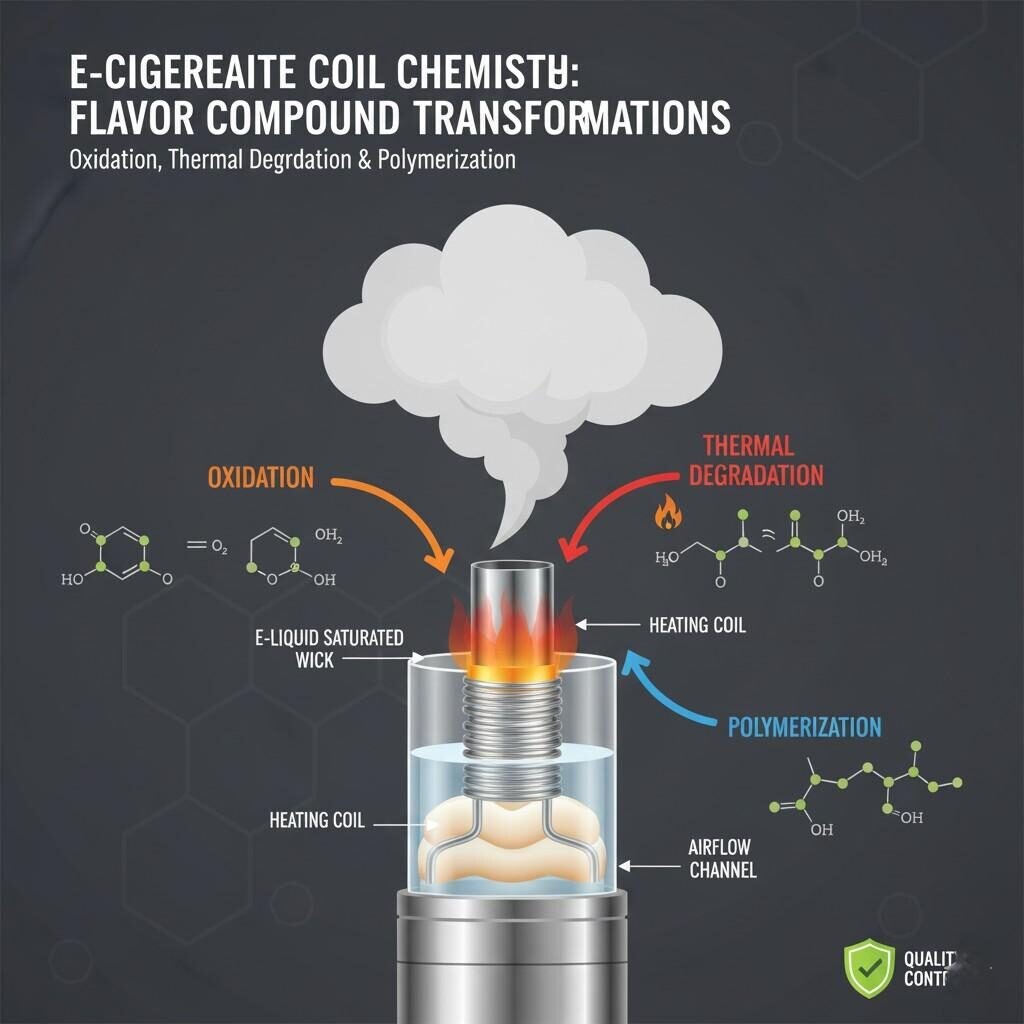

E-Cigarette Coil Chemistry: Flavor Compound Transformations

Flavor safety in e-liquids depends not only on the ingredients themselves but also on how they behave during aerosolization.

At 200–300°C (typical coil temperature), many compounds undergo decomposition:

This results in secondary irritants that may not appear in the original formulation.

Oxygen exposure accelerates the oxidation of terpenes and aldehydes, generating hydroperoxides. Some may react with propylene glycol (PG) to form acetals or hemiacetals, altering flavor perception and volatility.

Poor solubility between flavor components and carriers (VG/PG blends) can cause microscopic separation, leading to localized overheating and accelerated breakdown of flavor molecules.

Metal coils (nickel, kanthal, or stainless steel) can catalyze decomposition of certain compounds. Acidic or phenolic ingredients may accelerate corrosion, indirectly producing metallic nanoparticles in the aerosol stream.

For these reasons, flavor safety evaluation must include vapor-phase GC–MS and stability studies, not just raw material specification compliance.

Gas Chromatography–Mass Spectrometry (GC–MS) identifies volatile compounds before and after vaporization.

Advanced labs use TD-GC/MS (Thermal Desorption GC–MS) for vapor sample analysis, replicating real vaping conditions.

Each ingredient must be evaluated based on:

The Flavor and Extract Manufacturers Association (FEMA) provides valuable data on inhalation safety, although it primarily covers ingestion [⁶].

Global product registration often requires:

Adhering to documentation best practices ensures regulatory approval and protects your brand from compliance risks.

Maintain flavor concentration between 5–15% w/w to avoid thermal stress. Excess flavoring increases risk of reactive compound formation.

Modern synthetic analogs can mimic natural flavor molecules with better thermal performance and less oxidation potential. Examples:

Conduct:

These practices ensure long-term stability and safety consistency across production cycles.

Flavor Scientists in a Futuristic E-Liquid Lab

As global authorities continue to study vaping safety, new ISO standards and toxicological frameworks are emerging.

Key developments:

In parallel, scientific institutions are advancing research on flavor molecule toxicokinetics, thermal breakdown behavior, and bioaerosol safety modeling.

Leading companies like CUIGUAI Flavoring integrate toxicological review, GC–MS analytics, and compliance documentation into every formulation project.

By aligning innovation with safety science, manufacturers can lead the industry toward a cleaner, evidence-based flavor standard — protecting both consumers and brand reputations.

The vaping industry’s future depends on trust, transparency, and technical precision. Understanding which flavor ingredients to avoid is not merely a regulatory requirement — it is a moral and scientific responsibility.

By eliminating hazardous compounds like diketones, unstable aldehydes, and essential oils, and by adopting rigorous testing protocols, manufacturers can craft flavors that deliver exceptional sensory quality without compromising inhalation safety.

At CUIGUAI Flavoring, we specialize in developing vape-safe flavor systems backed by analytical chemistry, toxicology data, and regulatory compliance expertise. Our goal is to empower vape brands with flavors engineered for performance, safety, and global market readiness.

Ready to build your next compliant flavor line?

📩 Contact our experts for technical exchange or free e-liquid flavor samples tailored to your regulatory region.

👉 Request a Free Sample or Consultation

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at 【www.cuiguai.com】

[¹] U.S. National Institutes of Health (NIH). Flavoring Compounds in E-cigarettes and Respiratory Toxicity, 2023.

[²] Centers for Disease Control and Prevention (CDC). Diacetyl Exposure and Lung Disease, 2024.

[³] American Lung Association. Vaping and Essential Oils: Health Implications, 2024.

[⁴] European Chemicals Agency (ECHA). Carbonyl Compounds and Respiratory Hazards, 2023.

[⁵] World Health Organization (WHO). Chemical Safety of Inhaled Substances, 2024.

[⁶] Flavor and Extract Manufacturers Association (FEMA). GRAS Assessment and Flavor Safety Guidelines, 2023.

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy