Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Dec 05, 2025

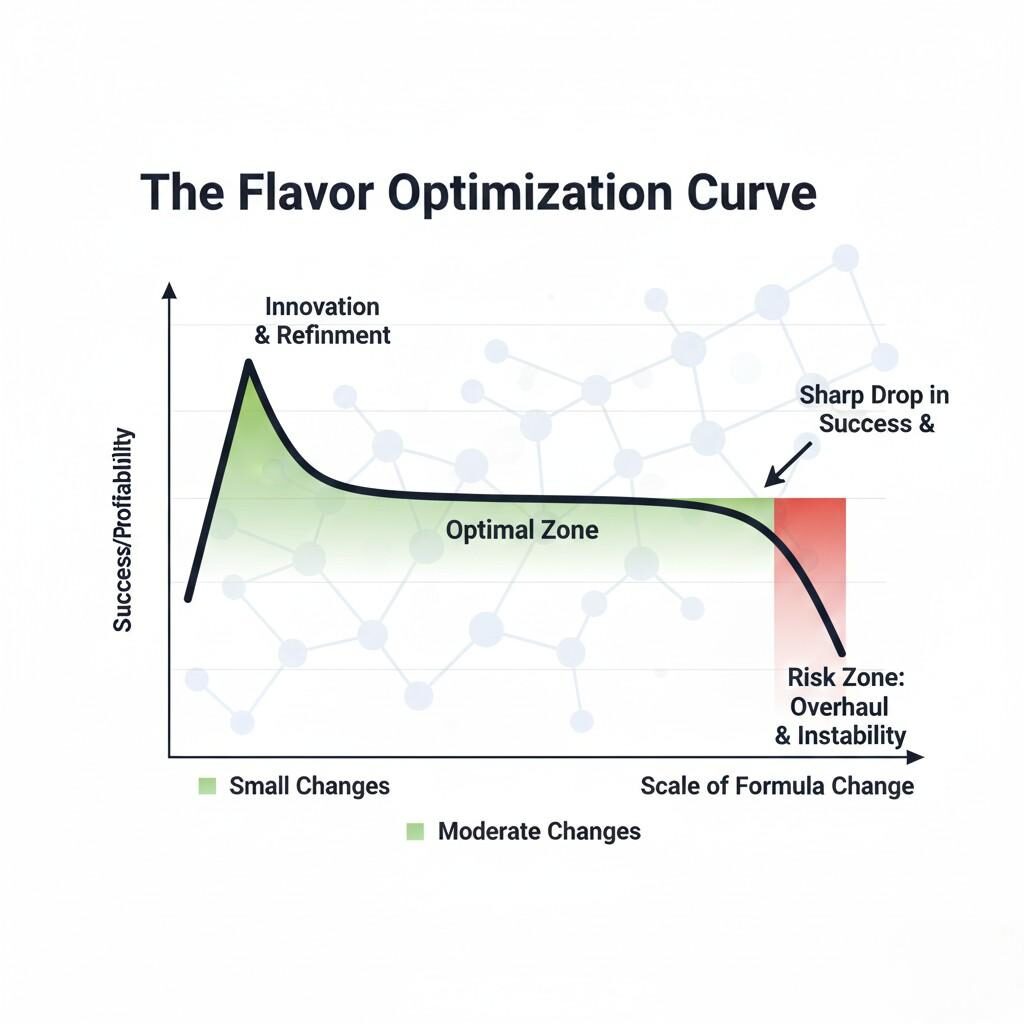

Flavor Optimization Curve

In the competitive world of electronic liquid manufacturing, the pursuit of the “next big thing” often leads to the costly, time-consuming, and frequently disappointing process of a complete flavor overhaul. A manufacturer identifies a market trend or a slight dip in sales and immediately seeks to reinvent their flagship product with entirely new ingredients and profiles.

As a manufacturer of high-quality flavorings, we strongly advocate for a counter-intuitive principle: small, highly precise flavor tweaks consistently deliver better results than large, radical overhauls. This philosophy is rooted not in conservatism, but in advanced sensory science, consumer psychology, and economic efficiency.

This article serves as a technical deep-dive into the “less is more” strategy of flavor development. We will explore the chemical reasons behind flavor stability, the cognitive biases that govern consumer acceptance, and the rigorous scientific methods that prove that a fractional adjustment to an existing formula is the smartest path to product optimization and market longevity.

The primary technical reason to favor small tweaks is to protect the molecular matrix of the existing e-liquid formula. A successful flavor profile is a complex, delicate equilibrium of volatile organic compounds (VOCs). Introducing major changes disrupts this balance, often leading to unpredictable and costly stability issues.

Flavor compounds interact non-linearly. In a four-component formula (A, B, C, D), removing component A and replacing it with component E (a major overhaul) means component E must interact safely and predictably with B, C, and D. The reality is that the new pairing often causes latent issues to emerge:

Flavor concentrations in e-liquids are already high-stakes formulations. Introducing a completely new flavor ingredient requires a full re-evaluation of its solubility, thermal stability, and long-term shelf life within the final PG/VG matrix.

Small adjustments, often below a 1% threshold, maintain the essential solubility and viscosity profile of the formula. Large overhauls can inadvertently push the solution past its saturation point, causing:

According to research in Food Chemistry and Toxicology journals, minor shifts in complex chemical systems (like flavor matrices) are generally preferable to radical changes, which often necessitate a complete re-validation of long-term shelf-life testing, a process that can take 12 to 24 months.

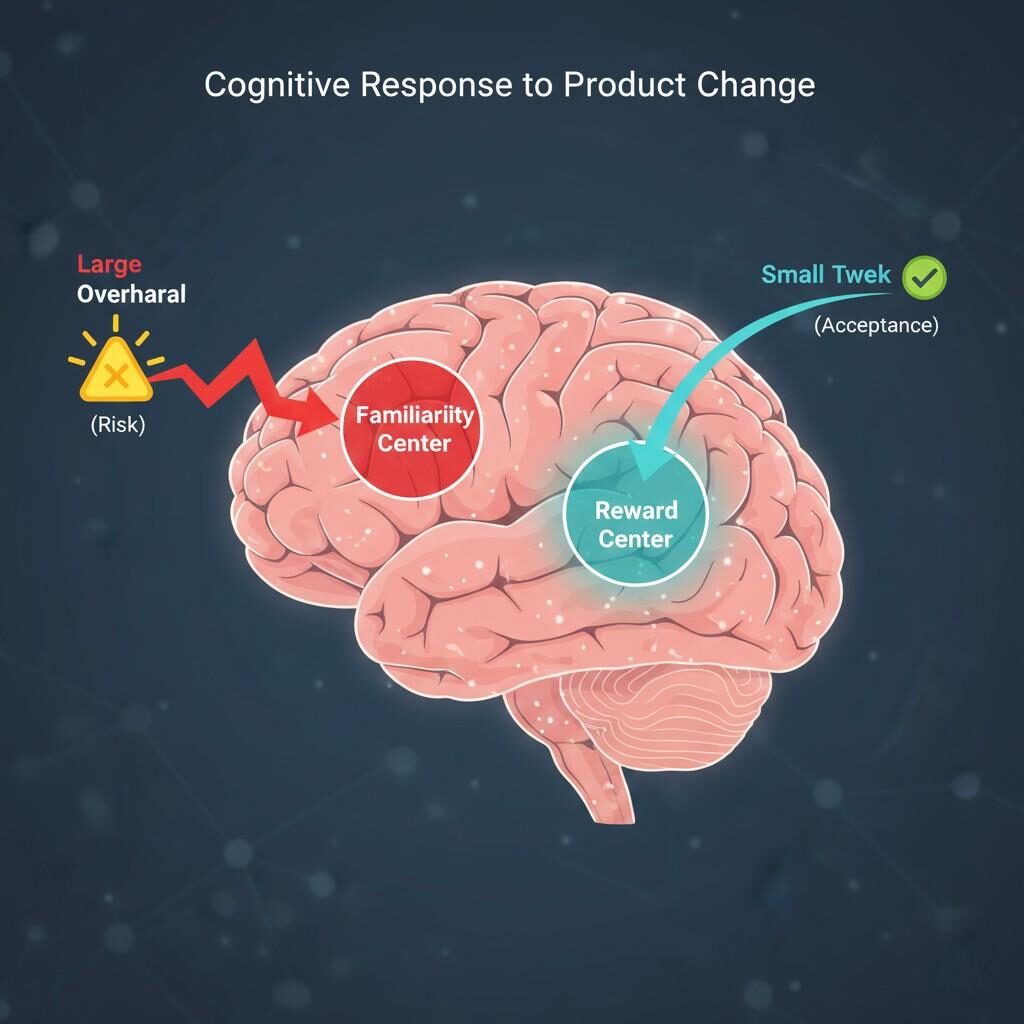

The sensory experience of vaping is governed by cognitive psychology and biological processes. Consumers, even sophisticated ones, exhibit strong biases toward existing, familiar flavors. Large overhauls ignore the physiological reality of flavor adaptation, while small tweaks leverage it.

Consumers develop loyalty not just to a brand, but to a specific, detailed sensory signature. The mere exposure effect dictates that consumers tend to prefer stimuli they have encountered before. For an existing, successful product, the consumer’s palate is already tuned to its unique profile.

Human olfaction experiences rapid adaptation or fatigue when exposed to constant, intense stimuli. If a manufacturer’s original intent was to create a strong, singular note (e.g., pure blueberry), the human nose may quickly tire of it.

Cognitive Response to Product Change

Beyond science and psychology, the case for small tweaks is undeniably strong on the grounds of cost, resource allocation, and regulatory compliance.

In markets governed by stringent regulations, flavor changes trigger massive compliance costs. Under the FDA’s Premarket Tobacco Product Application (PMTA) pathway and the EU’s Tobacco Products Directive (TPD):

According to a technical whitepaper published by a leading regulatory consulting firm, the documentation costs and time sink associated with introducing a new uncharacterized flavor substance far outweigh the costs associated with adjusting the concentration of an already approved substance within a stable concentration band.

Operational consistency is fragile in large-scale manufacturing.

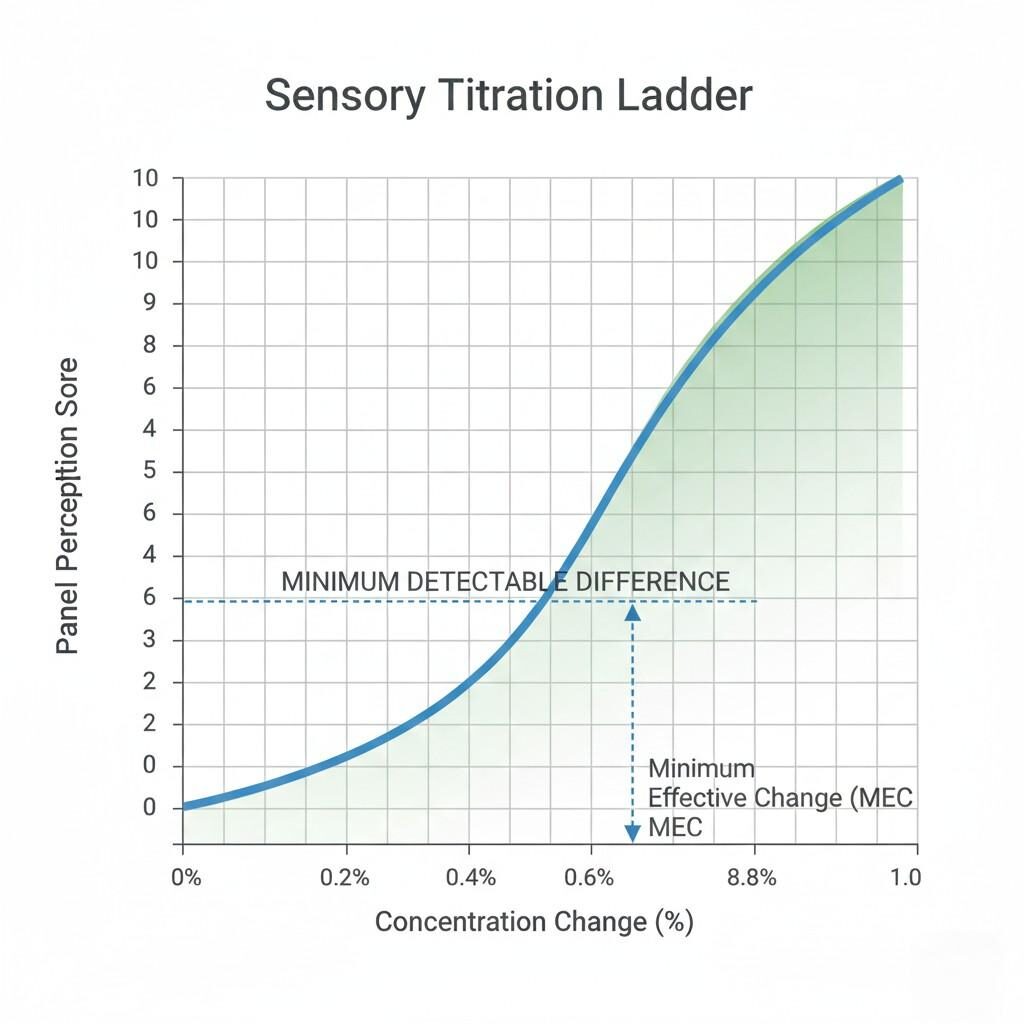

The science of small tweaks requires high-level technical expertise and analytical precision. It moves formulation from guesswork to validated science.

Before any tweak is implemented, its molecular impact must be quantified. We use Gas Chromatography-Mass Spectrometry (GC-MS) to create a molecular fingerprint of the existing successful formula (The Master Standard).

This process ensures that the integrity of the core flavor matrix is scientifically preserved, preventing accidental contamination or the introduction of trace impurities that could be found in a completely new raw material.

The goal of a small tweak is to find the Minimum Effective Change (MEC)—the smallest detectable adjustment that produces the desired sensory improvement. This requires meticulous sensory panel testing:

This methodology prevents over-correction, which is the leading cause of flavor drift and consumer confusion. By proving that a +0.25% change achieves the goal just as effectively as a +1.0% change, the manufacturer achieves the desired sensory result while significantly reducing cost and regulatory risk.

Sensory Titration Ladder Chart

The principle of small tweaks over large overhauls is a fundamental doctrine in industries that rely heavily on consumer habit and sensory signature, such as the soft drink and spirit industries.

When the Coca-Cola Company attempted a radical overhaul with “New Coke” in 1985, they ignored the psychological attachment consumers had to the sensory signature of the original formula. The resulting consumer outrage forced a rapid return to the original formula (Coke Classic), demonstrating that sensory familiarity often trumps perceived objective improvement.

In contrast, successful beverage companies constantly make small, incremental adjustments to maintain flavor consistency against shifting global water sources, ingredient procurement variations, and manufacturing environment changes. These small tweaks, invisible to the consumer, ensure the perception of a perfectly consistent product, thereby protecting billion-dollar brand equity. The e-liquid industry, due to its regulatory complexity, has an even greater need to adopt this stability-first methodology.

The era of radical, opaque flavor overhauls is receding. The future of premium electronic liquid formulation lies in precision, predictability, and scientific rigor. Small flavor tweaks—informed by analytical data, validated by sensory titration, and contained within regulatory comfort zones—are the most powerful tools available to manufacturers seeking to optimize quality, reduce costs, and maintain market stability.

For our clients, mastering the fine adjustment means achieving continuous product improvement without incurring catastrophic regulatory or consumer backlash. We provide the high-ppurity flavor molecules and the technical expertise to ensure that your next formula adjustment is precise, predictable, and profitable.

Precision E-Liquid Droplet

Stop guessing and start measuring. Ready to optimize your flagship formula with scientific precision?

We offer GC-MS Comparative Analysis Services and Technical Exchange to help you find the Minimum Effective Change (MEC) for your next product refinement.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.com]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Contact us today to ensure your next product refinement is a success, not an overhaul.

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy