E-liquid flavorings are among the most sensitive and compositionally complex ingredients in the vaping supply chain. While manufacturers typically focus on formulation precision and storage stability, the conditions during shipping—especially temperature and humidity—can dramatically alter a product’s flavor integrity before it even reaches its destination. In global export contexts, where shipments may span multiple climate zones and storage environments, understanding and mitigating environmental impact is essential.

This article explores the technical mechanisms by which humidity and temperature affect e-liquid flavorings during transit, identifies common flavor degradation patterns, and offers actionable best practices to optimize quality assurance (QA) procedures. The discussion includes analytical insights, packaging solutions, case studies, and international logistics challenges. We also highlight why CUIGUAI Flavoring, a brand specializing in export-grade vape flavorings, is a benchmark for transport stability, offering products specifically engineered for long-distance shipping resilience.

Journey Of Vape Flavoring

E-liquid flavors are typically composed of volatile aromatic compounds suspended in propylene glycol (PG), vegetable glycerin (VG), or a mix of both. These compounds include esters, aldehydes, ketones, and alcohols—many of which are thermolabile and highly reactive with moisture. Their behavior under thermal stress or moisture exposure is chemically predictable, but practically difficult to control without proper packaging and shipping protocols.

These transformations are not just theoretical. In real logistics chains, temperature swings of 30–40°C and RH (relative humidity) over 70% are common, creating a highly reactive transit environment.

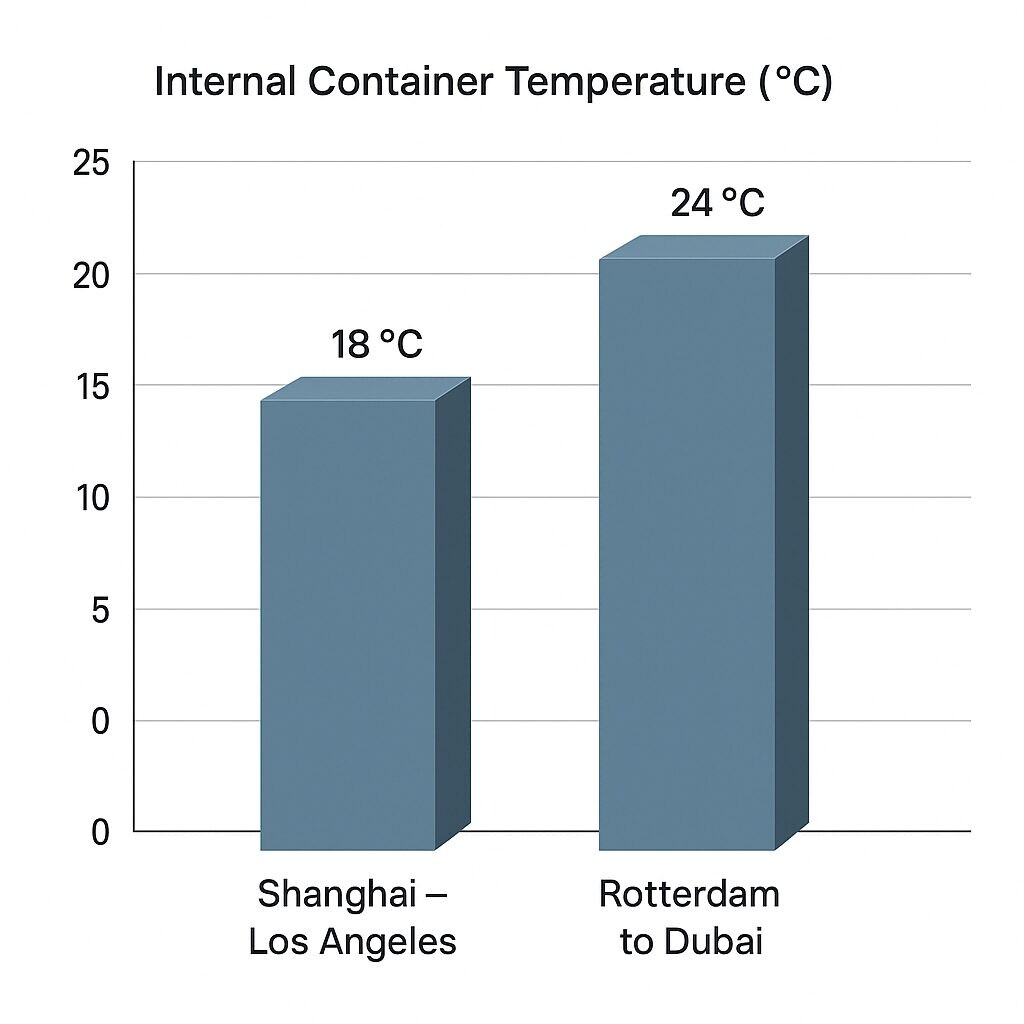

Internal Container Temperatures

Ocean freight containers left in sun-exposed ports or on-deck shipping can experience temperatures over 60°C. Even airfreight warehouses lacking active cooling can reach similar conditions. Prolonged heat causes:

In colder climates or during high-altitude air transport, freezing temperatures introduce new challenges:

Repeated freeze-thaw cycles accelerate emulsion destabilization and can lead to significant stratification.

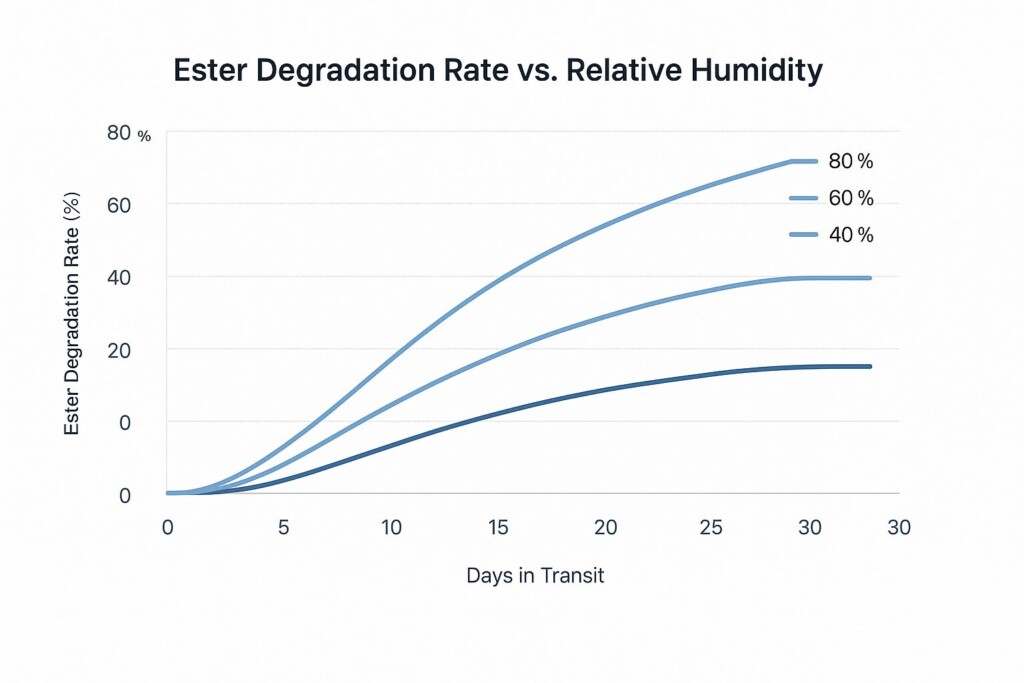

Ester Degradation Rate vs Relative Humidity

Moisture can infiltrate packaging via multiple mechanisms:

When moisture enters the system:

Such degradation is rarely obvious until flavors are mixed and evaluated—a major risk for final batch QA.

Professional flavor manufacturers mitigate shipping risks through advanced quality assurance strategies:

CUIGUAI Flavoring incorporates all these systems. Each batch destined for export undergoes triple-tier QA, real-time shipping telemetry, and is packed in ISO-validated materials. Clients receive arrival validation kits with reference samples.

Even for companies not operating at multinational scale, critical improvements can dramatically increase transit flavor quality:

Flavor instability can result in:

Flavor consistency starts long before mixing begins. Understanding how transit conditions affect the chemical integrity of vape flavorings is vital for maintaining brand reputation, user satisfaction, and regulatory compliance. Temperature and humidity impact is no longer a secondary concern—it is a frontline quality issue that defines premium flavor performance.

Brands that treat environmental transit control as a core QA domain—with validated packaging, controlled shipping routes, and rigorous traceability—will dominate in international markets. From cold-chain partnerships to desiccant engineering, the future of vape flavor quality is not just formulated, but transported.

Shipping Stability QA Essentials

Brand Callout: Looking for export-optimized vape flavorings? CUIGUAI Flavoring combines high-impact formulation with transit-proof packaging and QA, ensuring your flavors taste exactly as intended—no matter the journey.

Meta Description: Discover how temperature and humidity during shipping can degrade e-liquid flavorings. Learn actionable QA strategies and explore solutions from CUIGUAI Flavoring.

Keywords: flavor transport stability, shipping impact vape flavor, export flavor QA

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 21, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy