Imagine this: your brand’s top-selling e-liquid flavor is suddenly getting mixed reviews. Some customers say it tastes weaker, others say it’s harsher. You run tests and realize the flavoring hasn’t changed—at least, not on paper. What went wrong?

Batch-to-batch inconsistency in e-liquid flavoring is a silent brand killer. In a market driven by loyal, flavor-sensitive consumers, even minor variations in sensory quality can damage your brand’s reputation and bottom line.

This blog will uncover the technical causes behind flavor inconsistency and batch deviation in e-liquid formulations. More importantly, it provides practical, science-backed strategies to prevent these issues—whether you’re a flavor house, OEM, or brand formulator.

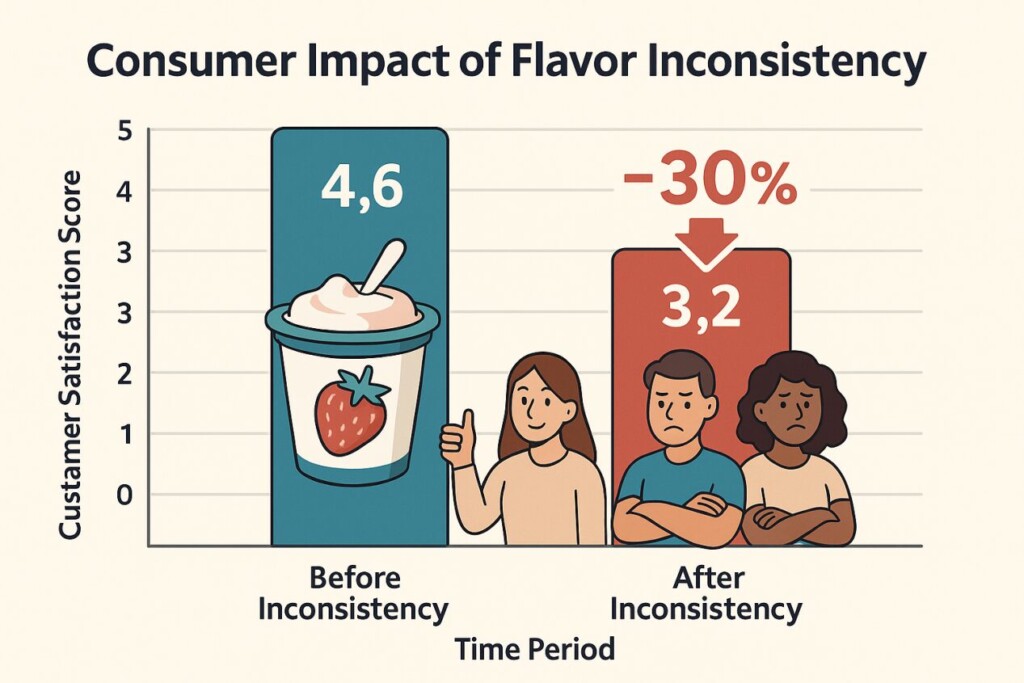

Consumer Impact of Flavor Inconsistency

In a saturated and brand-driven vape market, flavor consistency is not optional. It’s a competitive necessity. Flavor inconsistency leads to:

And the most dangerous part? Many companies don’t detect the problem until it’s too late.

The sensory stability of e-liquids is a delicate balancing act. Small variations—sometimes in the parts-per-million (ppm) range—can create major sensory differences.

Common technical causes include:

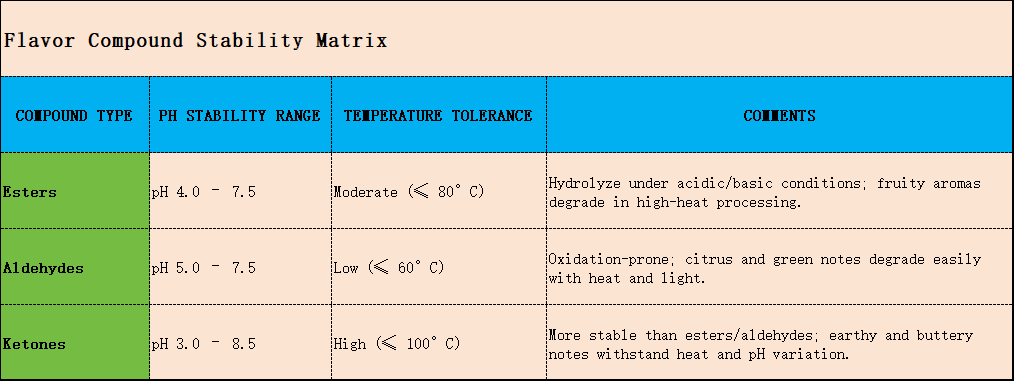

Chemical Stability Windows of Common E-liquid Flavor Compounds

Not all flavor ingredients are created equal—especially in high-stakes applications like e-liquid.

Natural extracts (e.g., tobacco absolute, vanilla CO₂) can vary significantly by harvest, geography, and processing method. Even when suppliers meet spec, minor changes in the terpene or acid profile can shift sensory perception.

While more consistent, synthetic flavor ingredients can vary by:

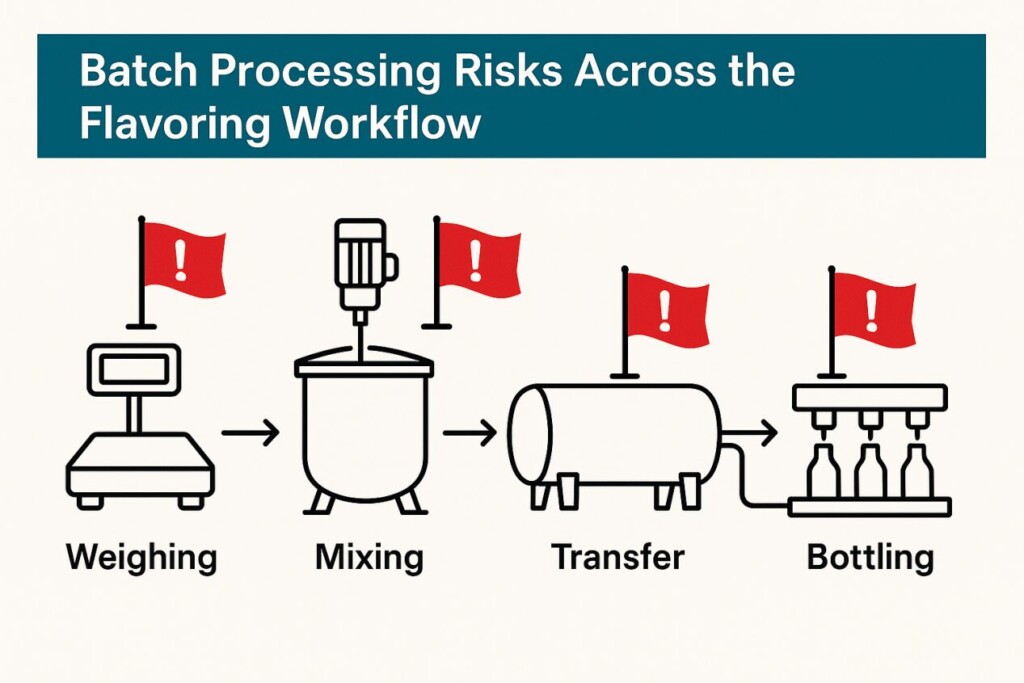

Flavoring instability doesn’t just stem from ingredients—it also comes from how you handle them.

Batch Processing Risks Across the Flavoring Workflow

Even the best-made flavorings degrade under the wrong conditions.

Many e-liquid flavor molecules—especially aldehydes and citrus oils—are highly sensitive to oxidation. If stored in semi-permeable plastics or transparent containers, their quality rapidly drops.

Repeated heat cycling (e.g., during summer shipping or warehouse storage) can:

Too many companies rely solely on final sensory tests—by then, it’s too late. Effective QC systems include:

Use blind triangle tests and reference samples every quarter to calibrate internal sensory teams. Do not over-rely on a single panelist or flavorist.

Work with flavor houses that offer:

Using premixed flavoring bases rather than reblending raw molecules in-house minimizes error sources. These bases should be made under controlled factory conditions with closed-loop QA.

A key preventative step: choose the right flavor supplier.

A trusted partner will:

✅ Recommended:

For companies needing flavor consistency across global markets, CUIGUAI Flavoring offers e-liquid flavorings with robust batch control, thermal stability certification, and global regulatory compliance—including EU TPD and US PMTA support.

Background: A mid-sized European e-liquid brand faced declining sales in its “Cool Berry Ice” SKU. Though COAs were clean, customers reported that the new batches tasted “flatter” and “less icy.”

Result: Within one quarter, complaints dropped by 92% and repeat orders increased.

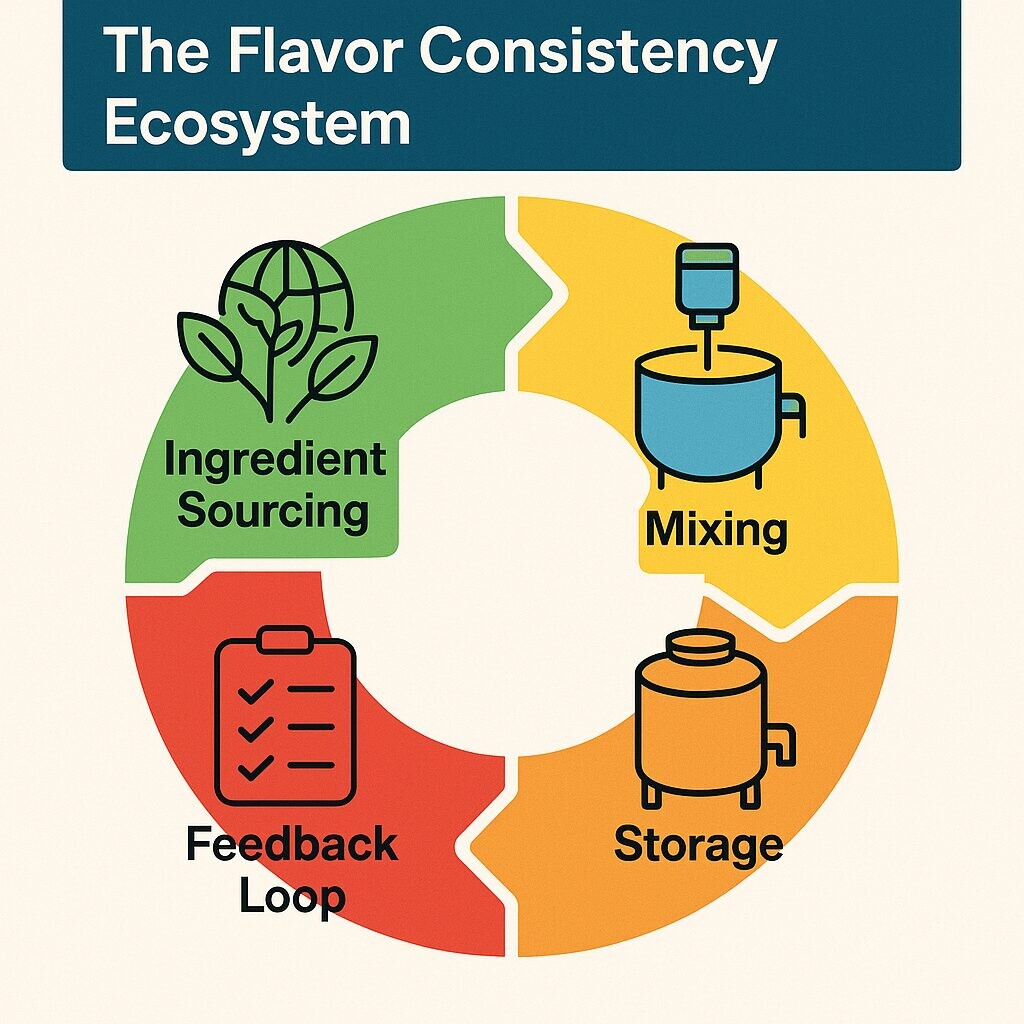

In the e-liquid business, flavor creativity wins you customers—but flavor consistency keeps them.

To protect your brand:

The Flavor Consistency Ecosystem

Consistency is not accidental—it’s engineered. If you’re struggling with flavor drift, CUIGUAI Flavoring’s lab-tested, heat-stable, and globally compliant flavorings are designed for batch-to-batch reliability. Talk to our formulation team today.

Keywords: flavor inconsistency, batch deviation, QC in flavoring, e-liquid quality assurance, vape formulation stability, EliquidFormulation, CUIGUAIFlavoring

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 2, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy