Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Dec 17, 2025

Diacetyl (2,3-butanedione) is a simple diketone used for its buttery or creamy flavor in foods and e-liquids. It delivers a rich, buttery aroma but is notorious for its inhalation hazard. Occupational exposure to diacetyl in the microwave popcorn and flavoring industries was linked to bronchiolitis obliterans – a severe, irreversible lung disease often called “popcorn lung.” In affected workers, the smallest airways become scarred and obstructed, leading to chronic cough, severe shortness of breath, wheezing, and fatigue. This condition is permanent and debilitating. In the late 1990s and early 2000s, multiple cases among popcorn factory employees highlighted how toxic diacetyl vapor can be. Animal studies confirmed it: inhaling butter flavor vapors caused airway cell death and inflammation in rats. By the early 2000s, U.S. health agencies like NIOSH and OSHA were issuing warnings about diacetyl, and flavor manufacturers learned to control exposure with ventilation and respirators to protect workers from the toxic vapors.

E-Liquid Chemical Safety Analysis

Given the serious health risks, reputable e-liquid manufacturers have moved away from diacetyl. After 2010 many companies adopted “diacetyl-free” flavoring policies. For consumers and regulators, the story of popcorn lung made an impact. The American Lung Association notes that related flavoring chemicals, like acetoin, can break down into diacetyl (the harmful compound) and that acetyl propionyl (2,3-pentanedione) – often used as a “safe” substitute – actually has similar health riskslung.org. In other words, simply swapping one diketone for another did not eliminate danger. The industry’s response has been proactive: many brands now routinely test both raw flavors and finished e-liquids to certify they contain negligible diketones. Warnings on e-cigarette packaging and regulatory guidance have followed. For example, some U.S. states now regulate these chemicals in flavor manufacturing. Overall, the shift away from diacetyl is driven by a precautionary principle and by emerging science.

Acetoin (3-hydroxy-2-butanone) is a naturally occurring compound with a mild buttery-cream aroma. It is found in dairy products, butter, and various fermented foods, and can also be produced synthetically. Chemically, acetoin is an α-hydroxyketone (C₄H₈O₂), not a diketone like diacetyl. It is colorless, water-soluble, and has a sweet, mild scent. In flavor formulation, acetoin contributes a creamy or yogurt-like note and is often used when formulators want a light buttery hint without the full punch of diacetyl.

Critically, acetoin is far less volatile than diacetyl. It boils around 150°C and its vapor pressure at room temperature (20°C) is very low (approximately 1.4 mmHg)femaflavor.org. By comparison, diacetyl’s vapor pressure is on the order of 55 mmHg at 20°Cfemaflavor.org, which means diacetyl more readily evaporates into air. Acetyl propionyl has an intermediate vapor pressure (~24 mmHg)femaflavor.org. This difference in volatility means that, under ambient conditions, far less acetoin is present as vapor to inhale, which aligns with its lower observed toxicity.

For context, acetoin is approved for food use. The U.S. FDA lists it as a permitted flavoring (21 CFR 182.60). As a food additive it is considered GRAS (Generally Recognized as Safe), and it appears in products like margarine, candy, ice cream, and fruit flavors. However, safety for ingestion does not automatically translate to inhalation safety. In the lungs, acetoin is handled very differently than when digested.

Laboratory studies have evaluated acetoin’s effects on the respiratory system. In controlled inhalation experiments, groups of rats and mice were exposed to acetoin vapor (6 hours per day, 5 days/week) at concentrations up to 800 ppm over periods of 2 weeks or even 3 monthsindustrialchemicals.gov.auindustrialchemicals.gov.au. Remarkably, these studies reported “no significant exposure-related adverse effects” in any of the animals at any tested doseindustrialchemicals.gov.auindustrialchemicals.gov.au. Animals remained healthy, with no significant changes in body weight or lung tissue pathology compared to controls. In other words, at realistic workplace-relevant doses, acetoin did not produce the airway fibrosis or inflammation seen with diacetyl.

Despite this favorable safety profile, formulators must still handle acetoin thoughtfully. The key issue is chemical stability: acetoin can oxidize to diacetyl, especially in the presence of air, light, or during prolonged storage. Scientific evaluations note that “in e-cigarette liquids, acetoin degrades to diacetyl”industrialchemicals.gov.au. In practical terms, this means an e-liquid with acetoin may slowly accumulate trace diacetyl over time. If such a liquid is later vaped, any formed diacetyl will be inhaled. To mitigate this, manufacturers can add antioxidants (like BHT), use amber packaging to block light, or produce fresh batches frequently. In summary, while acetoin itself has demonstrated a low inhalation hazard, preserving its purity and monitoring for diacetyl byproducts are essential.

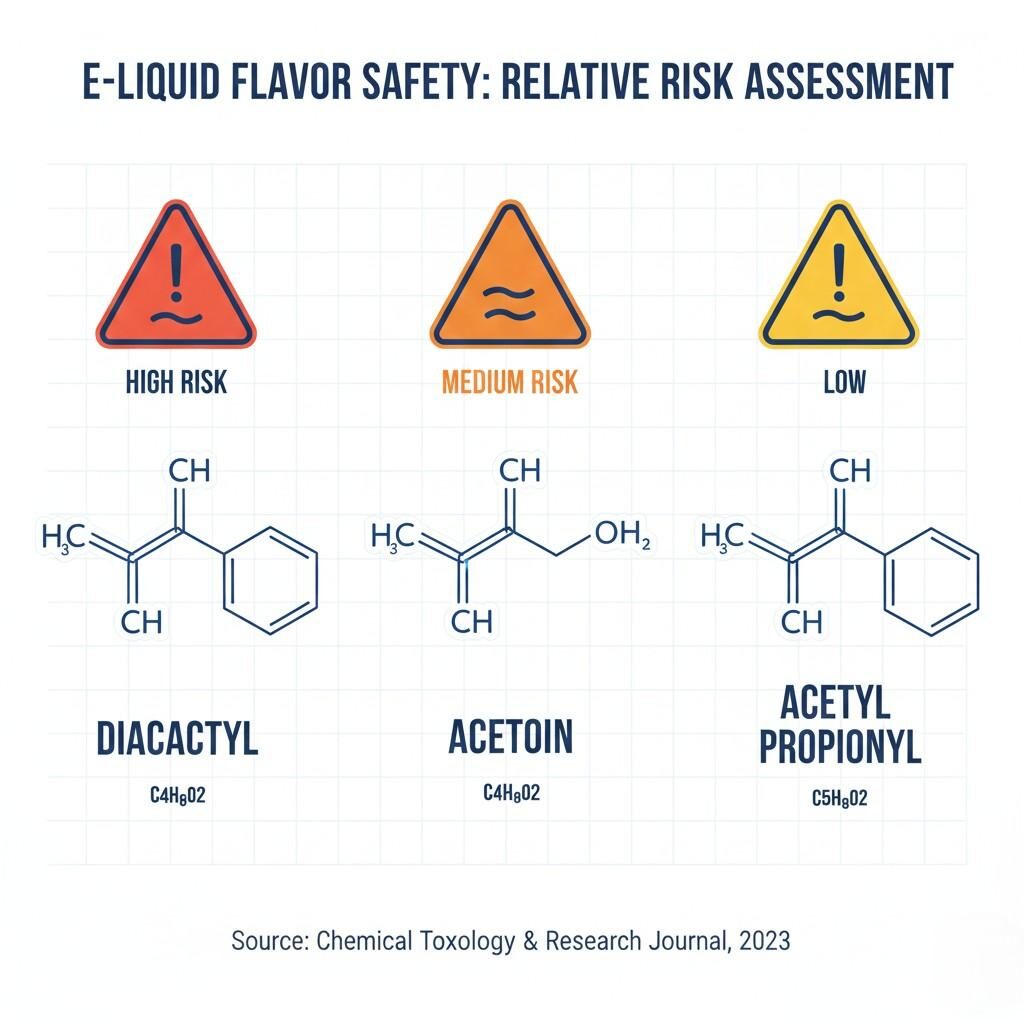

Diacetyl, Acetoin, and AP Risk Schematic

Acetyl propionyl, known in chemistry terms as 2,3-pentanedione, is another flavoring compound used for its buttery-caramel odor. It has a chemical formula C₅H₈O₂ and is structurally similar to diacetyl (essentially diacetyl with one extra carbon in the chain). It has a somewhat longer, slightly less sweet aroma. In e-liquid flavoring, acetyl propionyl has often been chosen to mimic diacetyl’s creamy notes. Unlike acetoin, acetyl propionyl is an α-diketone (like diacetyl) and vaporizes moderately easily (its vapor pressure is about 23.8 mmHg at 20°Cfemaflavor.org, much higher than acetoin’s).

Because of these similarities, toxicologists have treated acetyl propionyl with caution. Inhalation studies show that 2,3-pentanedione can harm the respiratory tract. A key finding is that 2,3-pentanedione has shown potency similar to diacetyl in causing airway damagencbi.nlm.nih.gov. In the NTP 3-month inhalation study (as described above), rodents exposed to high levels of 2,3-pentanedione showed clear adverse effects: at 50–100 ppm, rats and mice developed abnormal breathing patterns and sneezing during exposurencbi.nlm.nih.gov. Post-mortem, female rats exposed to 100 ppm had significantly higher lung weights and mild inflammation. These physiological changes indicate that the lungs were reacting to a toxic insult. In short, the animal evidence suggests acetyl propionyl is almost as potent as diacetyl at damaging airways.

There is limited human exposure data specifically for acetyl propionyl. However, given its chemical kinship to diacetyl, experts advise treating it as potentially hazardous. The American Lung Association explicitly notes that “acetyl propionyl… often used as a substitute for diacetyl, has similar health risks”lung.org. In practice, many companies now label acetyl propionyl with the same caution as diacetyl. Some vape e-liquid brands have eliminated it entirely from their formulas in recent years.

To compare at a glance:

Thus, acetoin is the milder alternative and is widely used for creamy notes, but even it requires care. Acetyl propionyl, while effective for flavor, demands strict handling and minimization, just as diacetyl does.

E-Liquid Quality Control Testing

Managing the safety of flavoring chemicals in e-liquids requires a comprehensive approach:

Exposure reduction best practices include: high-efficiency ventilation (local exhaust hoods), closed system processing, and wearing suitable respirators if working with heated or aerosolized flavors.

Quality control steps include: thorough vendor qualification (audits, documentation), batch sampling of incoming flavors, and ongoing analytical verification of finished goods. Our company can assist clients by providing testing guidance and recommended instrument methods.

Current regulations on these flavor chemicals vary by region, but the trend is toward tighter control. In some places (e.g. California), flavor manufacturing rules explicitly address diacetyl alternatives. Internationally, the European Union’s regulations already ban diacetyl and 2,3-pentanedione from e-cigarette liquids altogether. Regulatory bodies (like FDA in the US) have signaled that they monitor flavor constituents, even if formal limits for acetoin or acetyl propionyl are not yet in place.

Industry organizations also guide best practices. The Flavor and Extract Manufacturers Association (FEMA) and the International Fragrance Association (IFRA) maintain safety assessments of flavor chemicals. For example, the latest National Toxicology Program report (2023) confirms that acetoin, at high inhaled doses in animals, showed no adverse effectsindustrialchemicals.gov.au. These official findings are encouraging for formulators using acetoin. At the same time, IFRA recommends applying precautionary labels to inhaled products containing known airways irritants.

In summary, the professional consensus is clear: avoid diacetyl and 2,3-pentanedione in e-liquid flavors; use acetoin with transparency about its limits; and treat acetyl propionyl as a potential hazard. By adhering to published guidance and staying informed on new research, manufacturers stay ahead of regulations. For instance, after the EU’s 2022 flavor ban, many companies had already shifted away from diketones. Our team continuously monitors such developments to keep our customers compliant.

Diacetyl’s reputation as a lung hazard has led the flavor industry to seek alternatives. Acetoin and acetyl propionyl are the two most common substitutes in buttery e-liquid flavors. Scientific evidence indicates that acetoin is comparatively safe for inhalation, showing no lung toxicity in animal studiesindustrialchemicals.gov.au. However, acetoin can slowly oxidize into diacetyl if not properly handledindustrialchemicals.gov.au, so controls on storage and turnover are essential. Acetyl propionyl (2,3-pentanedione), by contrast, behaves almost like diacetyl in the lungs. Toxicology studies show it causes airway changes at moderate dosesncbi.nlm.nih.govncbi.nlm.nih.gov. Accordingly, it should be minimized or eliminated where possible.

Key recommendations: Source only high-purity, certified flavor ingredients; analytically verify that your final e-liquids are free of diacetyl and acetyl propionyl; use engineering and administrative controls to limit any inhalation exposure; and maintain full transparency (e.g. label declarations, SDS) about flavor contents. This careful approach allows manufacturers to deliver rich creamy flavors while safeguarding worker and consumer health.

Precision E-Liquid Flavor Blending

For further technical exchange or free samples of high-quality flavor ingredients, please contact us. Our experts are available.

We look forward to collaborating with you on safe and innovative e-liquid formulations.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy