In the intricate domain of vaping science, flavor perception is an experience shaped not only by the chemical composition of e-liquids but also by the physical parameters of aerosol delivery. One of the most critical factors that significantly modulate flavor perception is inhalation flow rate. This variable determines how aerosolized flavor compounds interact with the olfactory and gustatory systems during a vaping session.

Understanding the effects of vaping flow rate, flavor delivery, and the relationship of airflow vs flavor is essential for multiple stakeholders in the vape ecosystem, including e-liquid formulators, vaporizer engineers, and sensory scientists. More importantly, it allows brands to tailor user experiences and improve product satisfaction.

This comprehensive article offers an in-depth exploration of the science, engineering, and consumer implications of inhalation flow rate in e-liquid flavor perception. It integrates peer-reviewed research, experimental data, and industrial insights to deliver actionable conclusions.

Effect Of Inhalation Flow Rates

Inhalation flow rate, usually expressed in liters per minute (L/min), refers to the speed at which a vaper draws air through a device. This rate influences several downstream processes, including vapor temperature, particle size distribution, and the ultimate delivery of aroma-active compounds to sensory receptors.

Typical user profiles reveal wide variability:

Regulatory bodies such as CORESTA and ISO use fixed puffing regimens (e.g., 55 mL over 3 seconds at 30-second intervals) to assess e-cigarette performance. However, these conditions poorly represent real-world usage.

Recent studies advocate for dynamic puff simulation using human-subject data to better mimic realistic inhalation patterns. Device validation should therefore incorporate a range of flow rates.

Age, nicotine dependency, experience level, and even cultural norms influence puff duration, frequency, and intensity. For instance, younger vapers tend to favor higher airflow, while older users often prefer MTL draws with lower pressure.

A global survey found:

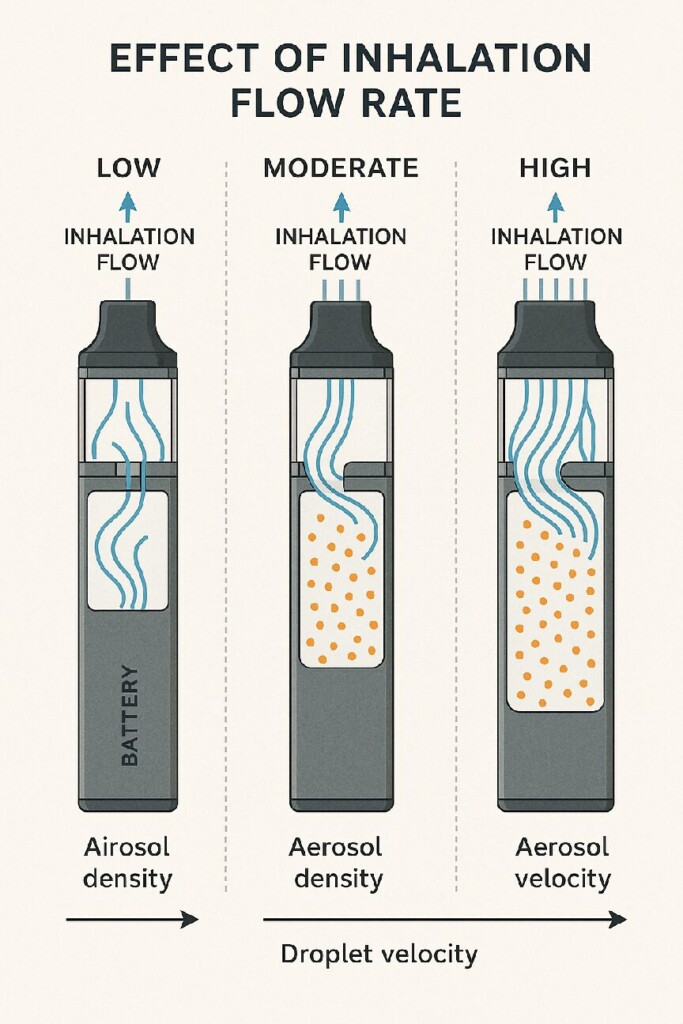

Vaporization occurs when e-liquid contacts a heated coil, transitioning into a supersaturated vapor that condenses into an aerosol. Inhalation flow rate impacts:

Higher flow rates can cool the coil too rapidly, leading to incomplete vaporization and muted flavor notes. Conversely, lower flow rates can cause over-heating or dry hits.

Particle size determines where in the respiratory tract aerosols deposit:

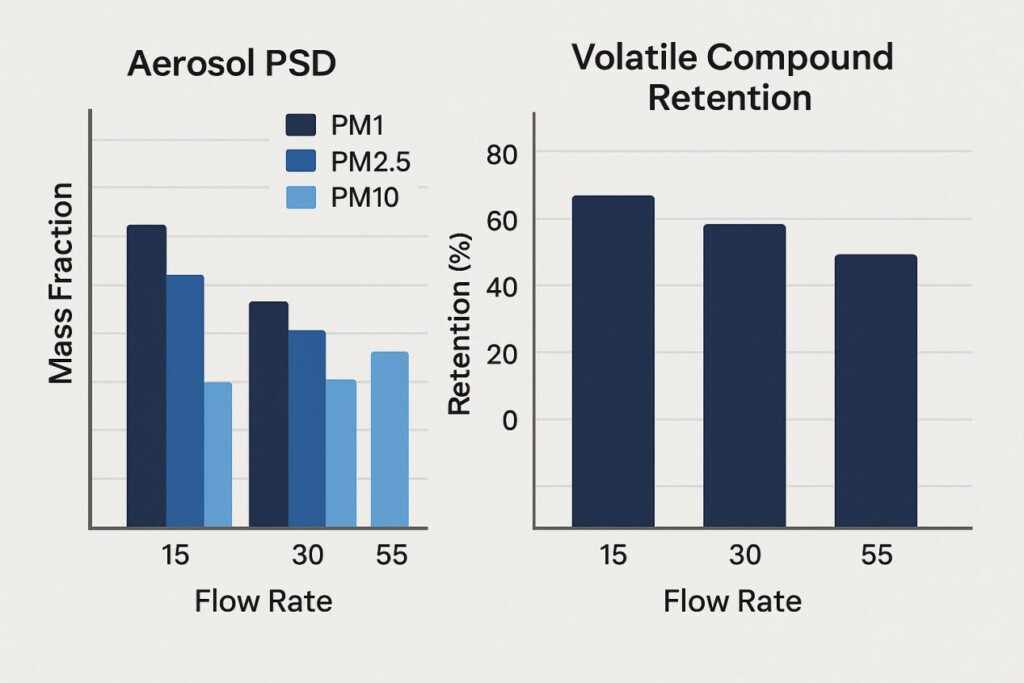

Studies show that high flow rates generate smaller particles (~0.9 µm median), which disperse quickly and offer less flavor intensity. Slower rates (~2–3 µm median) retain flavor potency but reduce vapor cloud volume.

Flavor molecules differ in volatility:

This explains why certain flavors are diminished in sub-ohm setups and flourish in MTL devices.

Comparison of Aerosol PSD and Volatile Compound Retention

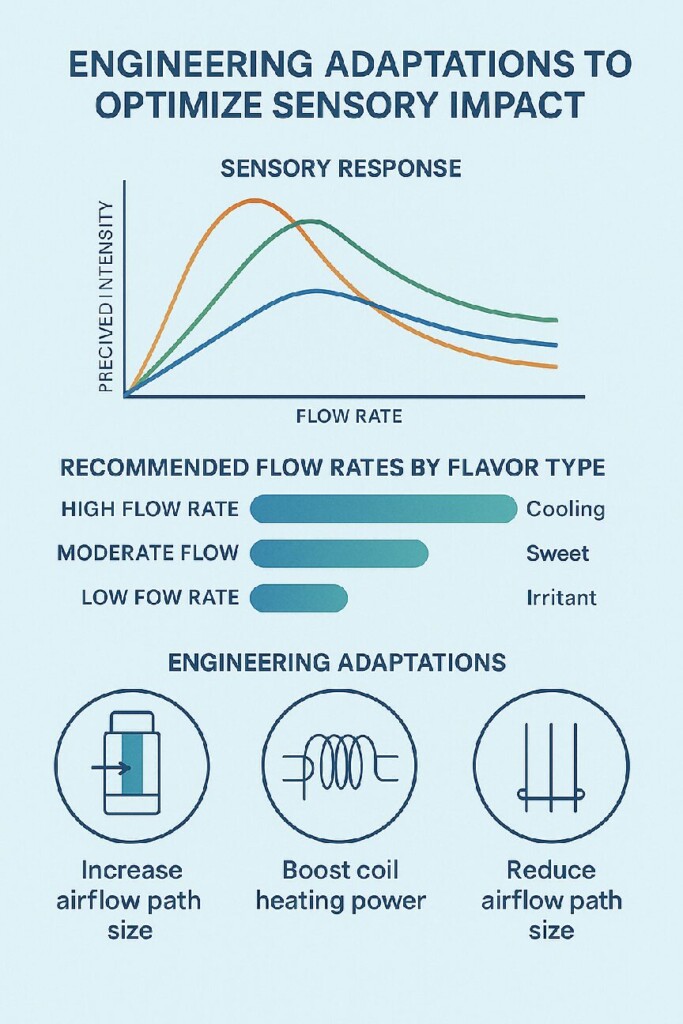

Flavor is a multisensory event driven primarily by retronasal olfaction. This route depends heavily on airflow patterns and vapor density.

Fast inhales reduce aerosol residence time in the nasal cavity, impairing retronasal flavor pickup. In contrast, slow and warm vapor enhances flavor note clarity, especially for nuanced flavors like tobacco blends or dessert profiles.

There is an optimal concentration window for flavor molecules:

High flow rates dilute flavorants, while low flow rates may oversaturate mucosa. Balanced delivery ensures maximal perception without overload.

Ambiance, previous food intake, hydration level, and even emotional state can amplify or suppress perceived intensity. Testing must account for these when assessing flavor delivery across flow rates.

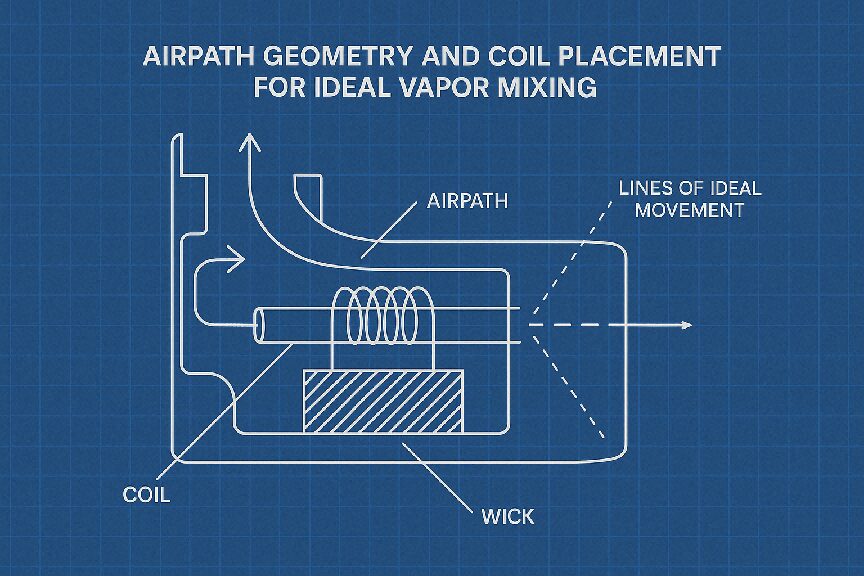

Modern coils vary from single-round Kanthal to mesh configurations with advanced heat distribution. Higher surface area supports even heating under high flow, while MTL coils focus on slow heat build-up.

Flow-rate matching strategies:

Internal air paths guide vapor flow, and their geometry alters turbulence and mixing. CFD simulations show that:

Top-tier brands like CUIGUAI Flavoring utilize encapsulated flavor compounds with varied release thresholds, ensuring that top, middle, and base notes are sequentially activated across flow intensities.

Airpath Geometry And Coil Placement For Ideal Vapor Mixing

A 2023 study from Shenzhen Vapetech Institute tested 12 commercial e-liquids across 5 flow rates. Key findings:

Blind testing panels (n=200) rated flavor richness under controlled puffing speeds. Users favored:

CUIGUAI’s R&D division deployed dual-phase testing to validate their formulations:

The result: flavor stability variance <5% across a 10–35 L/min range—a benchmark rarely matched in the industry.

Flavor houses must implement dynamic flow rate testing in their validation pipelines. Single-point evaluations are no longer sufficient. A triangulated approach involving:

is recommended.

Device manufacturers and liquid brands should provide flavor guides:

An informed consumer is more likely to appreciate a well-engineered product.

E-liquid and hardware pairing should be considered a brand service. Offering pre-tested bundles ensures optimal performance.

The fusion of sensory science, AI, and human-centered design will push the industry beyond flavoring into full-spectrum vapor experience engineering.

Inhalation flow rate is a pivotal but often underexplored parameter in flavor perception. Its influence spans aerosol thermodynamics, receptor biology, and consumer psychology. For vape product developers, a deeper grasp of this factor can be transformative.

CUIGUAI Flavoring remains at the forefront of this frontier, formulating e-liquids that deliver consistent flavor experiences across a wide range of devices and user behaviors. Their integration of micro flavoring techniques and cross-platform testing sets an industry benchmark.

Understanding and optimizing flow rate dynamics allows the vaping industry to deliver on the promise of rich, reliable, and satisfying flavor—one puff at a time.

Engineering Adaptations To Optimize Sensory Impact

Keywords: vaping flow rate, flavor delivery, airflow vs flavor,CUIGUAI Flavoring

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 13, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy