The Era of Predictive Flavor Science

In the competitive world of consumer products, a flavor is only as good as its stability. A delicious aroma profile at the time of manufacture is a promise; a consistent, unchanged flavor at the time of consumption is the ultimate delivery on that promise. Yet, ensuring this stability is a formidable challenge. A flavor formulation is a delicate ecosystem of hundreds of volatile organic compounds, all interacting with each other, the carrier base, and external environmental factors like heat, light, and oxygen.

Traditionally, predicting the shelf-life of a new flavor has been a slow, resource-intensive, and often imperfect process. It relies heavily on accelerated shelf-life testing, where formulations are subjected to extreme conditions in the hope of mimicking years of real-world aging. This method is costly, time-consuming, and provides a reactive rather than a proactive solution. It tells you if a flavor is stable after the fact, but it doesn’t help you optimize the formulation before you even mix the first batch.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) represents a paradigm shift in flavor science. By leveraging vast datasets of chemical, sensory, and environmental data, AI can predict flavor degradation with unprecedented speed and accuracy. This technology fundamentally transforms the flavor R&D cycle, moving from a slow, empirical process to a fast, data-driven one, ensuring product integrity and accelerating innovation at a pace never before possible.

Before we can apply AI to solve the problem of flavor stability, we must first understand the complex, multivariable nature of the problem itself.

Flavor degradation is not a single event but a series of complex chemical reactions. The most common mechanisms include:

Accelerated shelf-life testing, while a common industry practice, has significant limitations.

A single flavor formulation can contain hundreds of volatile compounds. The stability of the final product is not determined by a single compound but by the intricate interplay of all these molecules. A formulator may understand the properties of a few key compounds, but predicting how all of them will interact with each other and the environment over time is a task that is beyond human capability. This is where AI excels.

AI is not a single tool but a collection of models and techniques designed to find patterns in complex datasets. Applying AI to flavor stability requires a systematic approach to data collection, processing, and modeling.

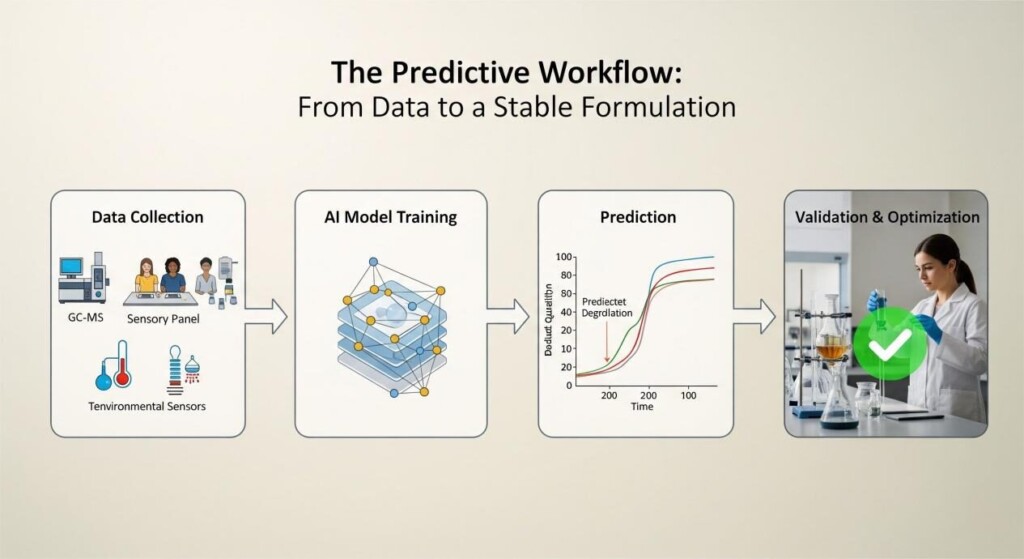

The AI-powered R&D process follows a clear workflow:

The quality of an AI model’s predictions is directly proportional to the quality of the data it is trained on.

Raw data from a GC-MS run is a complex chromatogram with hundreds of peaks. Feature engineering transforms this raw data into meaningful variables for the AI model.

Different AI models are used for different tasks.

The Predictive Workflow: From Data to a Stable Formulation

Integrating AI into the flavor R&D cycle is a strategic process that transforms the way formulations are developed and tested.

The first step is to build a comprehensive, digitized database, or “data lake,” of all historical R&D data. This includes every formulation ever created, the initial chemical fingerprint, all subsequent stability test data (chemical and sensory), and the environmental conditions of each test. This data is the lifeblood of the AI model.

With the data lake built, the AI model can be trained. The model learns to recognize complex, non-obvious patterns in the data. For example, it might discover that the ratio of a specific terpene to a certain aldehyde is a strong predictor of oxidation, a relationship that a human might never have found.

This is where the magic happens. A flavor chemist can now use the trained AI model to perform a “digital stress test.” They can input a new formulation and get an instant prediction of its long-term stability. The model can even suggest optimizations, such as “reduce the concentration of Compound X by 5% to reduce degradation,” or “add a specific antioxidant to enhance long-term stability.” This allows for a rapid, iterative process of digital formulation that was previously impossible.

While AI can provide powerful predictions, it is not a replacement for final, physical testing. The AI model’s prediction serves as a highly accurate “filter” that identifies the most promising formulations. Instead of testing 100 formulations, a formulator can use the AI to narrow the list down to the top 5, which are then subjected to rigorous, traditional stability testing for final validation.

The adoption of AI in flavor science is not just about R&D efficiency; it is a strategic business decision with significant economic and regulatory implications.

The “black box” nature of some AI models can be a concern. To build trust and ensure compliance, the industry is increasingly focused on Explainable AI (XAI). XAI models provide insights into why they made a certain prediction. This helps formulators understand the chemical drivers of instability, providing valuable scientific insights beyond a simple pass/fail result.

For industries like vaping, where product stability is a key component of regulatory submissions like the Premarket Tobacco Product Application (PMTA), AI can provide a powerful scientific rationale. While AI cannot replace final testing, the ability to show a regulatory body that a formulation was designed and optimized for stability using advanced predictive models is a significant advantage. A 2024 FDA guidance document hinted at the potential for advanced computational models to support product safety and stability assessments (Reference 3: FDA, 2024, “Guidance on Advanced Computational Modeling for Regulatory Submissions”).

The business case for AI in flavor science is clear.

The Promise of Precision

AI is not a futuristic concept; it is a practical tool that is already transforming flavor science. It is an extension of the flavor chemist’s expertise, a powerful assistant that can process and understand data on a scale that is impossible for a human.

By leveraging AI to predict flavor stability, the industry can move from a slow, reactive process to a proactive, data-driven one. It enables a new level of formulation precision, accelerates innovation, and, most importantly, ensures that every single bottle of flavor delivers on its promise of an exceptional and consistent sensory experience. The future of flavor is not about replacing human expertise but about augmenting it with the power of machine intelligence.

Keywords: AI vape flavor prediction, aroma degradation model

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Sep 19, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy