The surge in small-scale vape liquid producers has democratized the vape market. But as more startups enter this space, a common blind spot continues to sabotage product quality: improper flavor compounding. Unlike kitchen-style mixing, flavor compounding in e-liquids involves precision chemistry, sensory balance, and stability engineering.

What often seems like a simple blend of aromas quickly becomes a technical challenge when minor missteps lead to harsh throat hits, flavor burnout, sedimentation, or complete batch failure. This guide dives deep into the most frequent compounding errors that plague small-batch e-liquid producers—and how to avoid them.

“Precision-Compounded” vs “Flawed DIY Blend”.

Many new producers use food-grade or fragrance-grade flavors assuming cross-compatibility. But vape flavorings must meet distinct criteria:

Using non-inhalation-safe concentrates is one of the biggest regulatory and health risks a small producer can take. Failure to source professionally evaluated vape-grade flavors not only causes potential health liabilities but also undermines product consistency.

Common Mistake: Using bakery vanilla or candy flavors that contain propylene glycol but also emulsifiers, fats, or alcohols unsuitable for vaporization.

Flavor molecules vary in volatility—some flash off quickly, others linger. When a blend contains only volatile top notes (e.g., citrus, mint), the user gets an initial punch followed by flat vapor. Balancing top, middle, and base notes—similar to perfumery—is crucial.

Viscosity also matters. Overly viscous concentrates cause poor solubility, while thin alcohol-heavy flavors can lead to phase separation. Inconsistent droplet sizes or improper emulsification result in layered vape experiences, where only the dominant volatile compounds come through.

Solution: Use complete GC-MS analysis to understand molecule behavior under vaping temperatures.

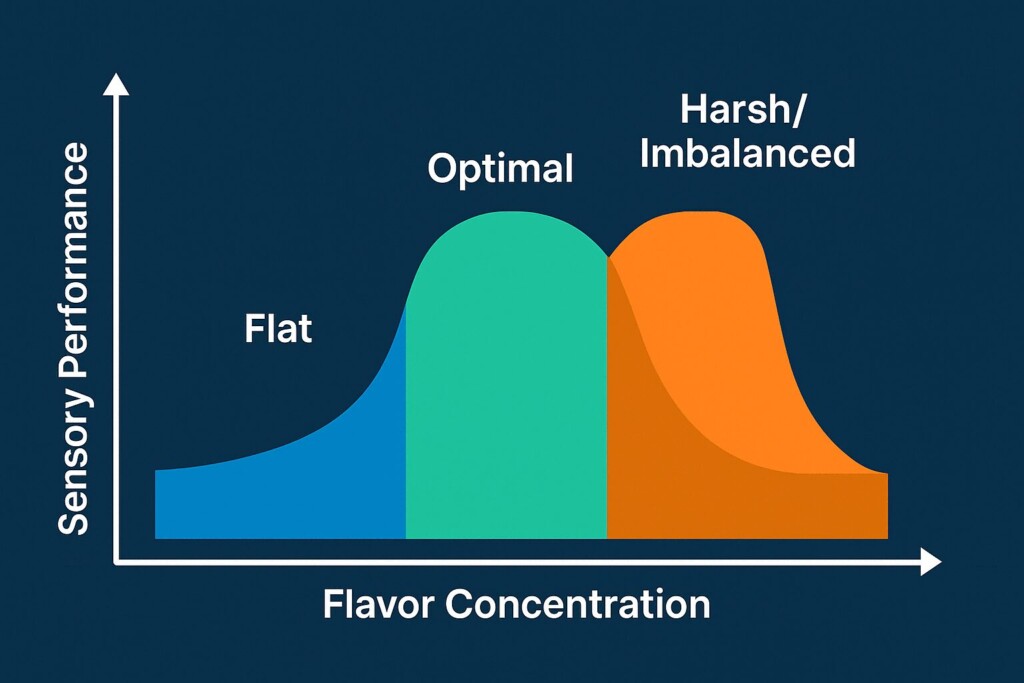

Overdosing flavoring doesn’t enhance impact—it often introduces harshness, bitterness, and coil gunk. Every compound has a sensory threshold. Exceeding it leads to off-notes and performance degradation.

Industry Guideline: 5–15% total flavoring by volume is typical; exceeding 20% often causes more harm than good. Individual ingredients, such as certain ketones or aldehydes, may dominate even at low concentrations, disrupting the intended balance.

Flavor Concentration vs Sensory Performance

Flavor molecules evolve post-mixing. A blend may smell good at day 0 but degrade after a week. Some ingredients (e.g., vanilla, creams, tobaccos) require steeping to mellow. Others (e.g., fruits, florals) may fade or change character. Alcohol-based flavor carriers, in particular, need time to volatilize or integrate fully.

Pro Tip: Create a steeping log. Evaluate aroma and vapor at day 0, 3, 7, 14, and 30. Test on various coil materials (kanthal, stainless steel, mesh) to assess impact on flavor delivery.

Flavor carriers must match your base system. A flavor designed for high-PG blends may not integrate in a 70/30 VG/PG mix, causing haziness or sediment. Likewise, essential oils, lipids, or gums used in some DIY recipes can remain insoluble and form visible droplets.

Use vape-specific flavorings with PG-compatible or blended carriers. CUIGUAI Flavoring, for instance, provides optimized solutions tailored for PG/VG stability, allowing predictable performance even in high-VG systems.

Shaking by hand doesn’t guarantee micro-level dispersion. Without homogenization, large flavor droplets create hot spots, separation, and inconsistent dosing. Poor mixing undermines flavor balance and batch repeatability.

Fix: Use magnetic stirrers, ultrasonic baths, or high-shear tools—even small-scale versions—for consistent emulsification. If resources are limited, a heated magnetic stir plate at 40–45°C can offer improved mixing for viscous concentrates.

Flavor compounds react with acids and bases. Introducing citric acid to fruity blends without buffering can cause phase shifts or harsh vapor. Nicotine, being mildly alkaline, interacts differently with acidic blends and may alter flavor perception.

Mistake Example: Using tart flavors with acidic preservatives (like potassium sorbate) in nicotine bases results in throat hit intensification and chemical imbalance.

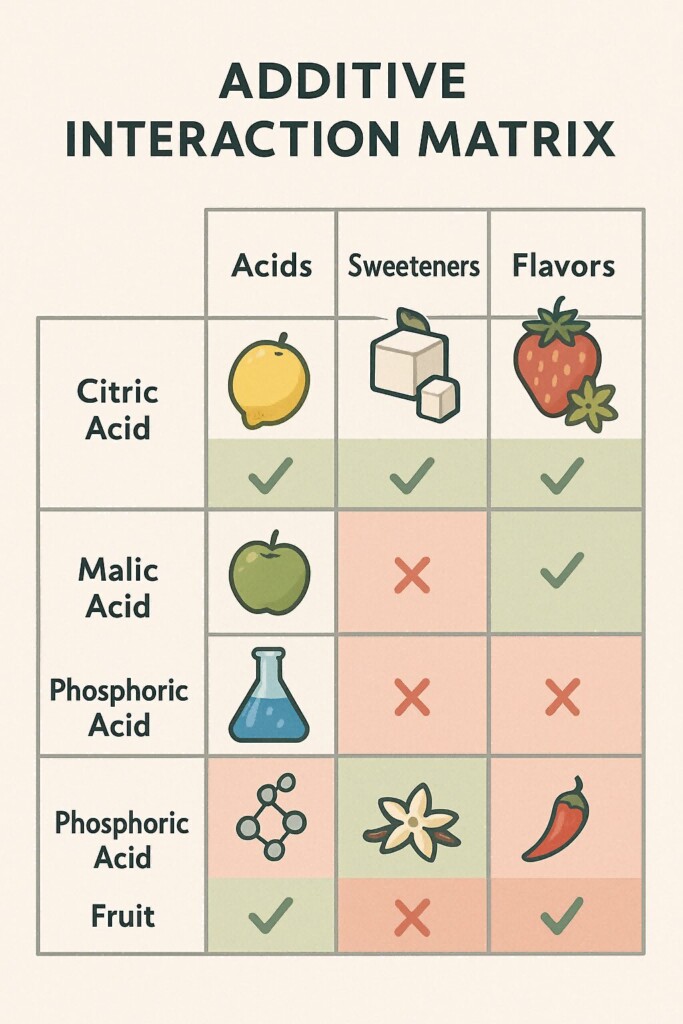

Super-sweet formulas are trending, but excessive sucralose or ethyl maltol leads to burnt coil buildup and muted notes. Sweeteners should enhance—not mask—flaws. Balance must be struck between sweetness, coil longevity, and layered perception.

Additive Interaction Matrix:

Advanced Tip: Use sweetener dampening techniques like vanillin-modulation or acetoin masking to maintain coil-friendly profiles.

Inconsistent batches arise when mixers fail to document exact volumes, brands, or steep times. This erodes consumer trust and makes quality control impossible. Even variations in VG grade or water content can alter flavor diffusion and sweetness perception.

Solution: Maintain a digital or physical flavor compounding log. Include:

Formulas that work at 30ml may not scale linearly to 1L or 5L. Flavor diffusion, heat generation, and pressure sensitivity change at larger volumes. Overconcentration of certain aldehydes or esters during scale-up can alter perceived sweetness or introduce harshness.

Use scale-up calculators and test pilot batches before full production. Always revalidate flavor performance through both sensory and chemical profiling post-scale.

A simple drop test (adding 2–3 drops of final liquid into a fresh tank and testing vapor) reveals:

Always perform sensory evaluation in blind trials when possible. Build a reference benchmark library with properly compounded control samples.

While costly, third-party GC-MS (gas chromatography-mass spectrometry) and HPLC (high-performance liquid chromatography) analysis can detect contaminants, oxidation byproducts, and unlisted allergens—essential for regulated markets. For export-oriented small producers, these tests are critical.

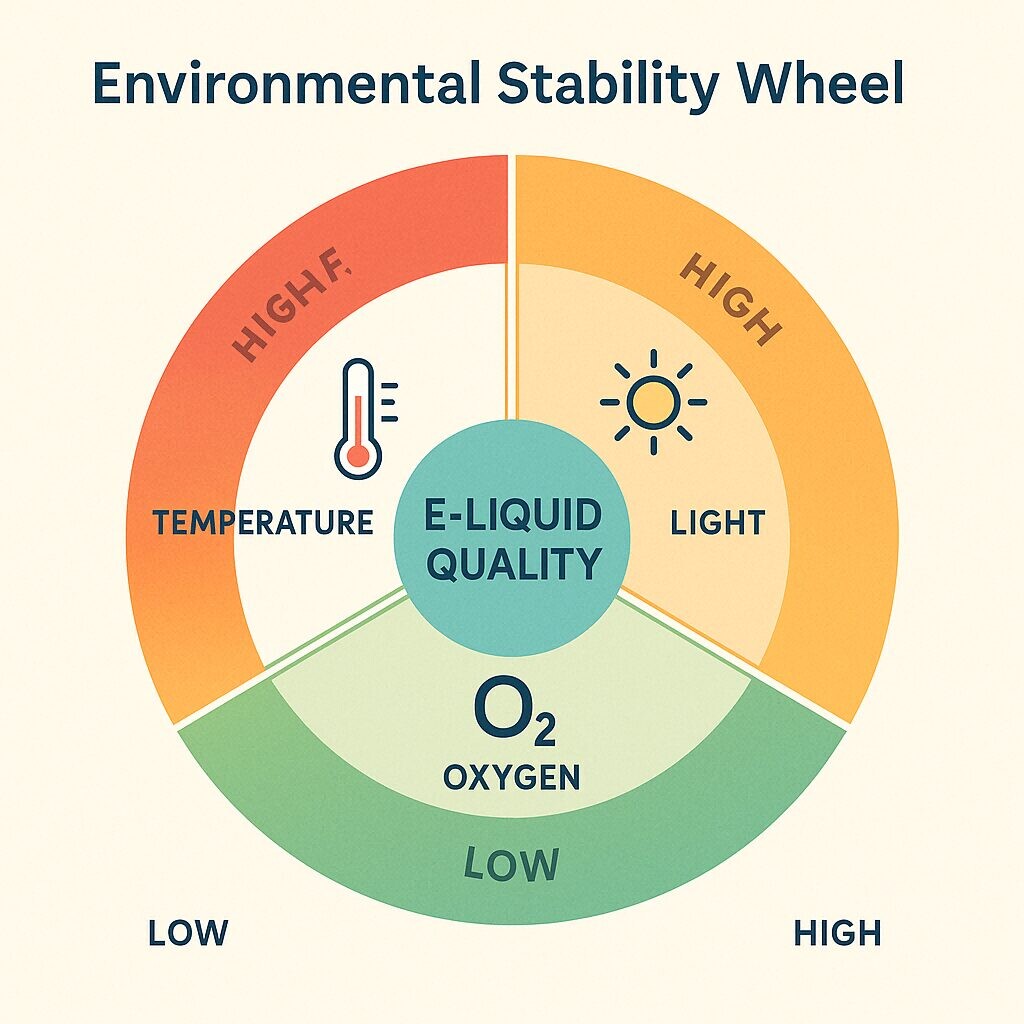

Storage protocols must include:

Environmental Stability Wheel

Flavor compounding in vape liquids is where art meets science. While creativity drives formulation, technical rigor ensures that ideas become viable, safe, and consistent products. For small-scale producers aiming to grow sustainably, mastering these fundamentals isn’t optional—it’s strategic.

Avoiding common compounding mistakes is the first step toward producing liquids that satisfy users and withstand market scrutiny. Work with scientifically-minded suppliers like CUIGUAI Flavoring, who engineer their vape-specific concentrates for high solubility, stability, and sensory fidelity across PG/VG systems.

Invest in quality tools, keep rigorous logs, and always test beyond the first puff. Your users—and your future self—will thank you. Focus not just on what tastes good today, but what performs well tomorrow.

Keywords: vape flavor blending errors, small batch flavoring, e-liquid formulation tips, DIY vape compounding, CUIGUAI Flavoring, flavor stability, PG/VG compatibility, e-liquid quality control, vape additive interactions, flavor scaling problems

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 20, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy