In today’s competitive e-cigarette market, flavor is everything. But it’s not just about exciting new taste profiles — it’s about consistency, reliability, and safety. For manufacturers and procurement teams, one of the most pressing concerns remains:

“How can we ensure that the flavoring ingredients we use are of high quality and consistent from batch to batch?”

This article explores the testing standards, stability mechanisms, and quality assurance practices behind premium e-liquid flavorings. We’ll unpack analytical methods, key regulatory benchmarks, and real-world approaches to batch-to-batch consistency. Our goal is to empower decision-makers with the tools to source better, safer, and more stable flavoring products.

High-quality e-liquid flavorings go beyond pleasing taste. They are:

| Region | Key Regulations | Focus |

| USA (FDA) | PMTA, GRAS compliance | Toxicological safety |

| EU (TPD) | REACH, TPD flavor limitations | Ingredient disclosure, safety labeling |

| China (GB) | GB30616, GB2760 | Contaminant limits, thermal degradation |

CUIGUAI Flavoring, a dedicated flavor house for e-liquid applications, ensures all raw materials conform to global regulatory and toxicological standards while undergoing internal testing protocols modeled on ISO 9001 laboratory practice.

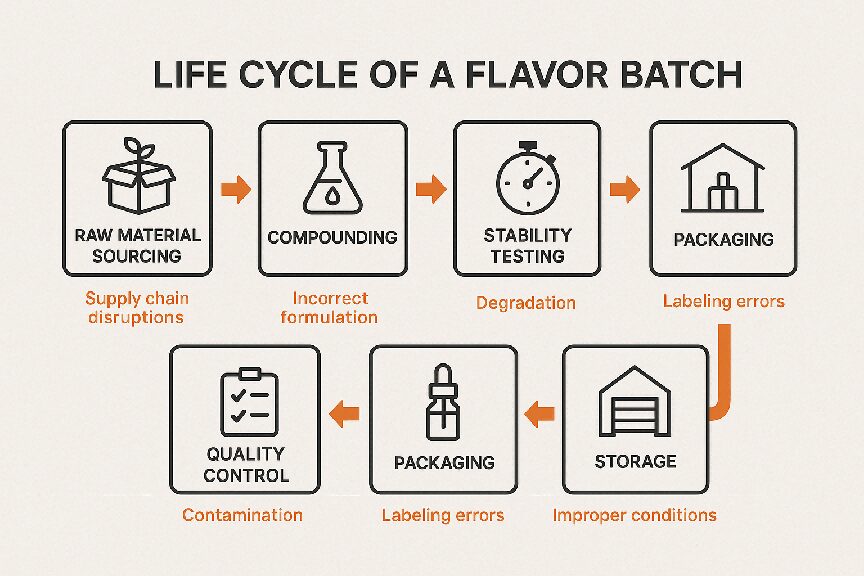

Batch inconsistency may be caused by:

Inconsistency is more than a technical flaw — it damages:

| Method | Purpose |

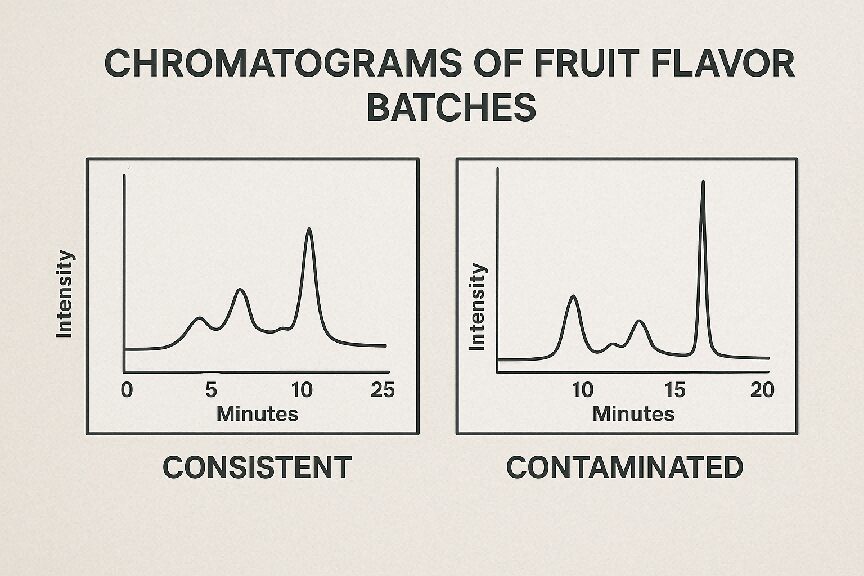

| GC-MS (Gas Chromatography-Mass Spectrometry) | Identifies volatile components and contaminants |

| HPLC (High-Performance Liquid Chromatography) | Measures non-volatile compounds |

| FTIR (Fourier Transform Infrared Spectroscopy) | Detects functional groups in molecules |

Organoleptic testing ensures flavor integrity across:

These are often validated with trained sensory panels and benchmarked against golden standards.

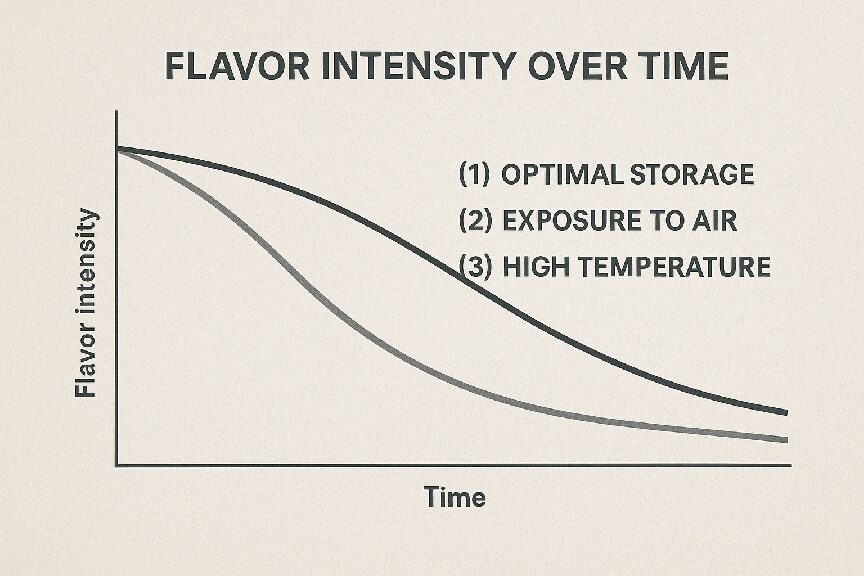

Stability refers to a flavor concentrate’s ability to:

| Factor | Risk | Mitigation |

| Light exposure | Breakdown of aromatic esters | Amber glass bottles, UV shielding |

| Temperature | Accelerated oxidation | Controlled cold-chain storage |

| pH balance | Affects shelf-life in base e-liquids | Balanced formulation |

| Air contact | Increases oxidation risk | Nitrogen flushing in bottling |

Maintain:

Best practices include:

Standardization involves:

A high-quality flavor supplier doesn’t just ship products. They provide:

We recommend CUIGUAI Flavoring for its scientific approach to flavor development, rigorous testing infrastructure, and batch documentation system tailored to e-liquid applications.

| Flavor Category | Stability Score(1-5) | Notes |

| Tobacco | 5 | Chemically stable, few reactive aldehydes |

| Dessert (e.g. vanilla) | 4 | Requires light protection |

| Fruit – Synthetic | 4–5 | Stable, especially esters |

| Flavor Category | Stability Score(1-5) | Notes |

| Fruit – Natural Extract | 2–3 | Prone to oxidation, variability in harvest |

| Citrus oils | 2–3 | Limonene oxidation risk |

| Herbal/floral | 3 | Volatile terpene degradation possible |

Flavor testing in R&D requires a multi-stage protocol:

In the high-performance world of e-liquids, flavor quality is a measurable, testable, and verifiable standard. Brands that treat flavorings as critical raw materials — worthy of documentation, traceability, and scientific scrutiny — will outperform those who chase low-cost, low-consistency options.

When choosing a flavor supplier, prioritize those with transparent QC protocols, robust testing documentation, and cross-batch consistency programs.

CUIGUAI Flavoring sets an excellent standard in this area, delivering stable, regulatory-compliant, and premium flavor solutions for the next generation of e-liquids.

| Flavor Name | Profile Type | Applications | Stability Rating |

| Mango Burst | Fruit | Pod devices, freebase vape | ★★★★☆ |

| Classic Tobacco | Tobacco | Salt-nic, disposable | ★★★★★ |

| Creamy Vanilla Bean | Dessert | Bakery blends, custards | ★★★★☆ |

| Icy Mint Crush | Cooling Agent | Menthol, mix-in | ★★★★★ |

Keywords: flavoring quality standards, flavor consistency, testing methods, flavor profile catalog, e-liquid flavorings directory, flavor description, flavoring procurement, e-liquid flavorings, fruit flavor concentrates, premium e-liquid quality

Article author: Toby Zhu

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy