Modern atomizers and molecular structure

The global vaping industry continues its meteoric rise, driven by innovation in device technology, nicotine delivery, and, crucially, flavor. While the foundational role of e-liquids lies in providing a stable medium for vapor production and fixed flavor profiles, a new frontier is emerging that promises to redefine the vaping experience: in-situ generation of fresh flavor compounds during the vaping process itself.

This groundbreaking approach moves beyond simply vaporizing pre-mixed flavors. Instead, it involves a sophisticated interplay of specialized e-liquid components and targeted heating, leading to the dynamic creation of new, nuanced, and intensely fresh aroma compounds precisely at the moment of inhalation. This revolution aims to deliver a more authentic, complex, and potentially customizable flavor experience, mimicking the dynamic flavor release found in natural foods and beverages.

This article delves into the technical intricacies of in-situ flavor generation during vaping. We will explore the underlying chemical principles, the engineering challenges, the potential benefits for consumers, and how this cutting-edge technology is set to transform the future of dynamic aroma delivery in vaping.

Traditional e-liquids rely on a fixed blend of flavor concentrates dissolved in a propylene glycol (PG) and vegetable glycerin (VG) base. While effective, this “static” flavor delivery can sometimes fall short of consumer expectations for freshness, complexity, and evolution during the vaping session.

The concept of in-situ flavor generation directly addresses these limitations by creating a dynamic, real-time flavor profile that can evolve and reveal new nuances with each puff.

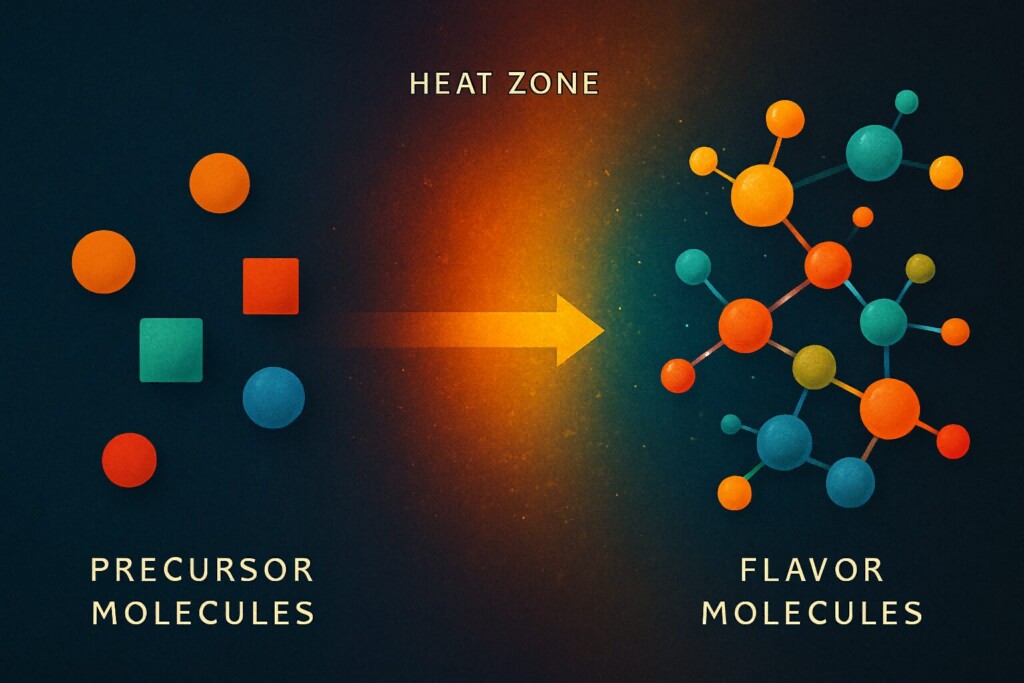

At its core, in-situ flavor generation leverages controlled chemical reactions that occur under the specific thermal conditions of a vaping device. This is a sophisticated application of reaction flavor chemistry within a confined, rapid-heating environment.

(1)Precursor Molecules:Instead of directly adding the final flavor compound, the e-liquid contains specific flavor precursor molecules. These are typically low-odor, stable compounds that, when subjected to heat, undergo a chemical transformation to produce desired volatile aroma compounds.

(2)Thermal Activation:The heat generated by the atomizer coil (at temperatures typically ranging from 150-300°C) provides the activation energy for these reactions. The precise control over temperature and heating rate is critical for dictating which reactions occur and at what speed.

(3)Maillard-like Reactions:Similar to the Maillard reaction in cooking (responsible for browning and savory notes in food), certain non-enzymatic browning reactions can be designed to occur in-situ. These involve amino acids and reducing sugars (or sugar alcohols) as precursors, generating complex pyrazines, furans, pyrroles, and other heterocyclics that contribute roasted, bready, caramel, or nutty notes.

(4)Lipid Oxidation/Breakdown (Controlled):While uncontrolled lipid oxidation is undesirable, controlled thermal breakdown of specific fatty acid precursors can release short-chain aldehydes, ketones, and esters that contribute fruity, creamy, or savory notes. This requires extremely precise control to avoid rancidity.

(5)Esterification:Alcohols and carboxylic acids can react under heat to form esters, which are often associated with fruity and floral aromas.

(6)Aldol Condensations & Cyclizations:These reactions can form cyclic compounds with unique aromatic properties.

(7)Enzyme-Mimetic Reactions (Hypothetical/Emerging):Future advancements might explore catalysts or conditions that mimic enzymatic reactions, allowing for the generation of extremely fresh, natural-like flavors (e.g., green notes, fresh cut fruit aromas) that are typically unstable.

Implementing in-situ flavor generation requires meticulous engineering and formulation to ensure safety, consistency, and optimal performance.

(1)Coil Design & Temperature Control:The atomizer coil must provide uniform and precisely controllable heat to trigger the desired reactions without causing general degradation or harmful byproducts. Materials and heating profiles are critical.

(2)Precursor Stability:Precursor molecules must be stable within the e-liquid formulation during storage, preventing premature reaction. They should also be non-toxic and form non-toxic byproducts.

(3)Reaction Kinetics:Understanding the rate at which reactions occur is crucial to ensure optimal flavor generation within the very short timeframe of a puff.

(4)Byproduct Management:All reaction byproducts must be fully characterized and proven safe for inhalation. This is a paramount safety consideration.

(5)Flavor Balance:The generated flavors must integrate harmoniously with any pre-existing “static” flavors in the e-liquid, creating a balanced and desirable overall profile.

(6)Device-Specific Formulation:Different vaping devices (e.g., low-wattage pods vs. high-wattage mods) have varying heat delivery characteristics, requiring tailored precursor formulations.

Molecular Transformation and Flavor Formation

For consumers and the vaping industry alike, in-situ flavor generation offers compelling advantages that redefine the sensory experience.

Innovative electronic cigarette equipment

The integration of in-situ flavor generation represents a significant leap forward for the vaping industry. It moves beyond static experiences, offering a dynamic, authentic, and highly engaging sensory journey that more closely mimics the complexity of real-world flavors.

Manufacturers who embrace this technological frontier and forge strong partnerships with pioneering flavor houses like CUIGUAI Flavoring will be uniquely positioned to:

The future of flavor science and its impact on consumer experience

In conclusion, in-situ generation of fresh flavor compounds during vaping is not just an incremental improvement; it’s a paradigm shift. By leveraging sophisticated chemistry and engineering, this technology promises to unlock a new era of dynamic aroma delivery, offering unparalleled freshness, authenticity, and complexity. For manufacturers brave enough to venture into this exciting frontier, and with the right flavor partner like CUIGUAI Flavoring, the future of vaping is set to be more flavorful, engaging, and revolutionary than ever before.

Keywords: in-situ flavor generation, dynamic aroma vape, flavor precursors, e-liquid flavors, vape flavor technology

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Aug 01, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy