Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 26, 2026

Ethyl Maltol Analysis in Laboratory

In the rapidly evolving landscape of the vapor industry, the quest for the perfect “sweet” profile has become a cornerstone of brand success. From the early days of basic fruit blends to the current era of complex “disposable-style” ultra-sweet liquids, manufacturers have faced a persistent challenge: how to deliver the intense, nostalgic sweetness of spun sugar without destroying the consumer’s hardware within hours.

At the center of this challenge are two of the most important molecules in the flavorist’s toolkit: Maltol and Ethyl Maltol (EM). While they are often discussed interchangeably in hobbyist circles, their chemical properties, sensory impacts, and thermal stability profiles are vastly different. For a manufacturer, choosing the wrong one—or using the right one at the wrong concentration—can lead to muted flavors, “vaper’s tongue,” or the rapid accumulation of carbonized residue known as “coil gunk.”

This article provides a deep-dive technical analysis of these two pyranones, offering a roadmap for maximizing cotton candy notes while maintaining industry-leading coil longevity.

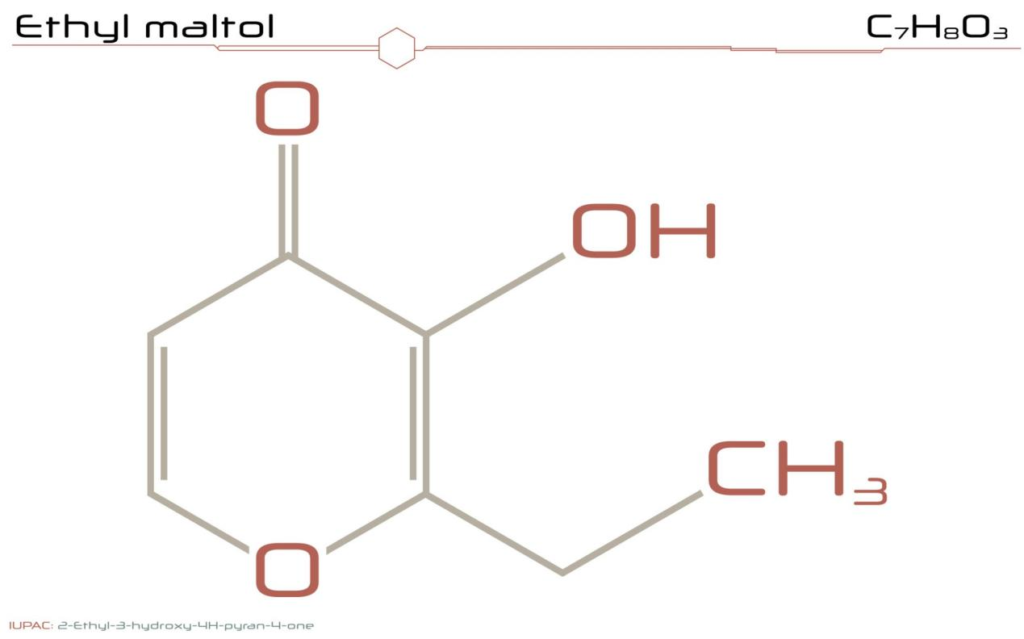

To optimize any flavoring, we must first understand its molecular structure. Both Maltol and Ethyl Maltol belong to a class of compounds known as pyranones. Specifically, they are hydroxypyranones.

Maltol, or 3-hydroxy-2-methyl-4H-pyran-4-one, is a naturally occurring organic compound. It was first isolated from the bark of larch trees and is found in abundance in roasted malt, chicory, and even pine needles. In the food industry, it has been used for over a century as a flavor enhancer and a scent fixative.

Maltol is characterized by its:

Ethyl Maltol (2-ethyl-3-hydroxy-4H-pyran-4-one) is the synthetic “big brother” of Maltol. In this molecule, the methyl group found in Maltol is replaced by an ethyl group. This seemingly small change in the alkyl chain significantly alters the molecule’s interaction with human olfactory and gustatory receptors.

Ethyl Maltol is characterized by its:

Ethyl Maltol Molecular Structure

Scientific Insight: According to the National Center for Biotechnology Information (NCBI), the increased lipophilicity of the ethyl group in Ethyl Maltol allows it to cross the mucus layer of the olfactory epithelium more efficiently than Maltol, which partially explains its significantly lower detection threshold in humans. [Source: PubChem, NIH].

In e-liquid formulation, we are not just designing taste; we are designing an experience. The “mouthfeel” of vapor—its perceived thickness, smoothness, and weight—is heavily influenced by these two molecules.

One of the most critical aspects of using Ethyl Maltol is understanding its ability to “mute” or “round off” other flavors. In small amounts (0.5%–1% of a 10% PG solution), EM acts as an equalizer. It hides the “chemical” edges of certain artificial fruit notes and blends the top and base notes together.

However, once the concentration exceeds 2%, a phenomenon known as olfactory saturation occurs. The heavy EM molecules dominate the vapor’s profile, making complex notes like strawberry or lemonade feel “flat” or “dull.” This is often misdiagnosed by consumers as “vaper’s tongue,” but it is actually a structural failure in the liquid’s formulation.

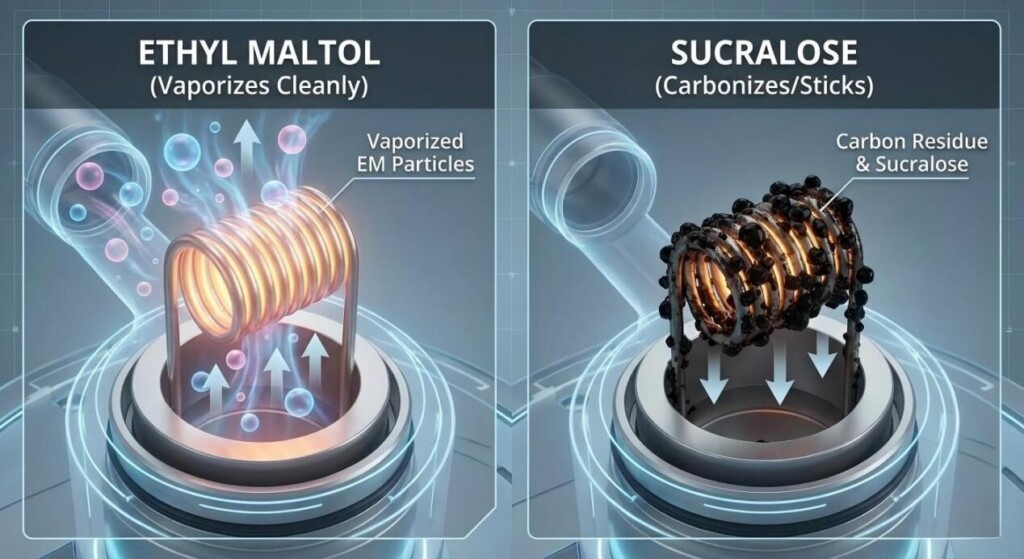

For a flavoring to be “coil-friendly,” it must vaporize cleanly at the temperatures generated by a vape coil (typically between 180°C and 280°C).

Unlike Sucralose, which is a carbohydrate and decomposes at high temperatures, Maltol and Ethyl Maltol are relatively stable.

Because Ethyl Maltol has a significantly lower melting point and a manageable boiling point, it transitions into a vapor phase much more easily than Sucralose. This is why a “Cotton Candy” flavored liquid (using only EM) will always be cleaner on a coil than a “Sweetener” heavy liquid (using Sucralose).

Ethyl Maltol vs. Sucralose Infographic

While Maltols are cleaner than sugars, they are not immune to degradation. Under extreme heat or in the presence of nitrogenous compounds (like certain nicotine salts or tobacco extracts), Maltols can participate in the Maillard reaction. This chemical reaction between amino acids and reducing sugars (or their derivatives) leads to the formation of melanoidins—the dark pigments that turn your cotton brown and your coil black.

To minimize this, manufacturers must ensure their liquids have a balanced pH and that the flavoring carriers (PG/VG) are of the highest pharmaceutical purity (USP/EP Grade).

A common issue in large-scale e-liquid manufacturing is precipitation. If a flavorist adds pure Ethyl Maltol powder directly to a high-VG base, the result will likely be a cloudy liquid that eventually “crashes out,” leaving crystals at the bottom of the bottle.

The industry standard for using EM is to create a 10% solution in Propylene Glycol (PG).

In the current “Max VG” market, solubility becomes even more difficult. Vegetable Glycerin is a poor solvent for many aromatic compounds, including EM. If you are manufacturing a 70/30 or 80/20 VG/PG liquid, you must ensure that your total PG content (including the PG in your flavor concentrates) is sufficient to keep the Ethyl Maltol dissolved. If the concentration of EM in the final liquid exceeds its solubility limit in the specific VG/PG ratio, crystallization will occur during transit or storage in colder climates.

Ethyl Maltol and PG Mixing

For manufacturers, the choice between these two molecules depends entirely on the target profile.

| Feature | Maltol | Ethyl Maltol |

| Chemical Formula | C6H6O3 | C7H8O3 |

| FEMA Number | 2656 | 3487 |

| Relative Sweetness | 1x (Baseline) | 4x – 6x |

| Aroma Description | Toasted, Caramel, Malt, Warm | Cotton Candy, Jammy, Fruity, Airy |

| Melting Point | 161°C | 90°C |

| Recommended Usage | 0.25% – 1.0% | 0.5% – 2.5% (as 10% dilution) |

| Primary Application | Bakeries, Tobaccos, Custards | Fruits, Candies, Soda, “Cold” flavors |

| Coil Impact | Very Low | Low to Moderate |

Manufacturer’s Tip: If you are developing a “Sugar Cookie” or “Caramel Macchiato” flavor, Maltol is superior because its toasted notes complement the bakery base. If you are developing a “Pink Lemonade” or “Gummy Bear” flavor, Ethyl Maltol is the only logical choice.

In the modern regulatory environment, transparency is no longer optional. Both Maltol and Ethyl Maltol are classified as GRAS (Generally Recognized As Safe) by the Flavor and Extract Manufacturers Association (FEMA) and the FDA.

According to a study published in the Journal of Food Science, Maltols are rapidly metabolized and excreted by the body, showing no significant toxicity at the concentrations used in flavoring. [Source: IFT / Journal of Food Science]. For e-liquid manufacturers, ensuring your Ethyl Maltol is 99% pure and free from heavy metal contaminants is vital for passing PMTA (Premarket Tobacco Product Application) or TPD (Tobacco Products Directive) testing.

The most successful “Cotton Candy” flavors on the market are rarely just Ethyl Maltol. Professional flavorists use molecular synergies to create a three-dimensional taste.

To avoid the “dryness” that high EM concentrations can cause, many manufacturers blend EM with Erythritol. Unlike Sucralose, Erythritol provides a “cool” sweetness on the tongue and adds a moist mouthfeel to the vapor without increasing the rate of coil caramelization.

Ethyl Maltol and Vanillin (or Ethyl Vanillin) are the “Power Couple” of the flavoring world. A ratio of 4:1 (EM to Vanillin) creates a creamy, marshmallow-like sweetness that is highly addictive to the palate. This blend is often used to create “thick” vapor profiles in high-end dessert liquids.

While we have established that EM is cleaner than Sucralose, many manufacturers still find their “Cotton Candy” liquids gunking coils. Why?

High-strength nicotine, particularly low-quality nicotine salts, can react with Ethyl Maltol over time. This oxidation process creates dark compounds that settle on the coil. Using ultra-purified nicotine with a clear color is essential for maintaining a “clean” sweet liquid.

In an effort to compete with disposables, many open-system liquid manufacturers are “over-flavoring” their liquids (total flavor percentage exceeding 20%). When the flavor load is this high, the PG/VG carrier cannot efficiently vaporize all the aromatic solids. The excess flavor “cooks” onto the coil. By using a more potent Ethyl Maltol strategy, you can achieve the same sweetness at a lower total flavor percentage, resulting in cleaner coils.

As an e-liquid manufacturer, you must educate your consumers. High concentrations of EM are stable at standard wattages, but in “Super-Sub-Ohm” tanks running at 100W+, the heat can be intense enough to cause thermal degradation of even the most stable flavor molecules.

When moving from a 10ml test batch to a 1,000-liter production run, the behavior of Ethyl Maltol can change.

Professional Data: A report from the European Flavor Association (EFFA) emphasizes that the stability of pyranones is significantly increased when stored in opaque, airtight containers at temperatures below 25°C. [Source: EFFA Industry Standards].

Why are we so obsessed with Maltol and EM? The answer lies in human evolution. Humans are biologically hardwired to seek out the taste of “cooked sugars” as a sign of high-calorie, safe food. Ethyl Maltol triggers these ancient reward pathways more effectively than almost any other aroma chemical.

When a consumer vapes a liquid with a well-balanced EM profile, they experience a “dopamine hit” similar to eating actual candy. For a brand, this means high “all-day-vape” (ADV) potential and strong brand loyalty. However, if the liquid gunks their coils, that loyalty disappears. The manufacturer who masters the Ethyl Maltol / Coil Longevity balance wins the market.

| Problem | Likely Cause | Solution |

| Crystals at the bottom of the bottle | EM concentration exceeded solubility limit in VG. | Increase PG ratio or reduce EM %; Ensure 10% PG dilution is used. |

| Flavor tastes like “cardboard” | “Muting” due to too much EM. | Reduce EM concentration to below 1.5%; Add a “bridge” note like Maltol. |

| Liquid turns dark brown quickly | Reaction between EM and low-grade nicotine or heat. | Use higher purity nicotine; Store in amber bottles; Check pH levels. |

| Coils turning black in 2 days | Presence of Sucralose or over-flavoring. | Replace Sucralose with an EM/Erythritol blend; Lower total flavor %. |

| Harsh “throat hit” in a sweet liquid | Acidic fruit notes clashing with EM. | Use 0.5% Maltol to “round off” the acidity and provide a smoother exhale. |

The vapor industry is moving away from “dirty” sweeteners and toward sophisticated aromatic engineering. By understanding the molecular difference between Maltol and Ethyl Maltol, manufacturers can create liquids that are not only delicious and nostalgic but also respectful of the consumer’s hardware.

Maximizing cotton candy notes is not about adding more sweetener; it is about the strategic use of high-purity Ethyl Maltol, the careful balancing of PG/VG ratios, and the avoidance of thermal degradation. As we look toward future regulations and a more discerning consumer base, the science of the pyranone will remain the most powerful tool in the flavorist’s arsenal.

Premium Cotton Candy E-Liquid Lineup

Are you looking to elevate your flavor profiles or solve a persistent coil-gunk issue? Our team of master flavorists and chemical engineers is here to help. We provide high-purity Ethyl Maltol crystals, pre-stabilized 10% PG dilutions, and custom-engineered “Cotton Candy” bases for global manufacturers.

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

| 📍 Factory Address | Room 701, Building 3, No. 16, Binzhong South Road, Daojiao Town, Dongguan City, Guangdong Province, China |

Let’s engineer the perfect puff. Contact us today for a technical consultation.

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy