Introduction: The pursuit of the perfect vaping experience is an ongoing quest that drives relentless innovation in the e-liquid industry. While flavor development, nicotine delivery, and device technology rightly capture significant attention, a critical, often unseen, aspect of quality and safety lies in the meticulous removal of unwanted byproducts. Even in highly purified e-liquid components, trace impurities or compounds formed during manufacturing and storage can detract from flavor integrity, contribute to harshness, or raise safety concerns. Enter photocatalytic degradation – a revolutionary, environmentally friendly technology that leverages the power of light to selectively break down these undesirable substances, promising a new era of ultra-pure, uncompromised e-liquid flavors. This blog post will delve into the intricate science and transformative potential of photocatalytic vape cleaning, exploring how this advanced method can achieve unparalleled byproduct removal and elevate the standard of e-liquid quality.

Liquid purification experiment under light exposure

E-liquids, at their core, are complex chemical mixtures. Despite stringent quality control, various unwanted byproducts can emerge, influencing the user sensory experience and potentially posing health risks:

These unwanted byproducts can lead to:

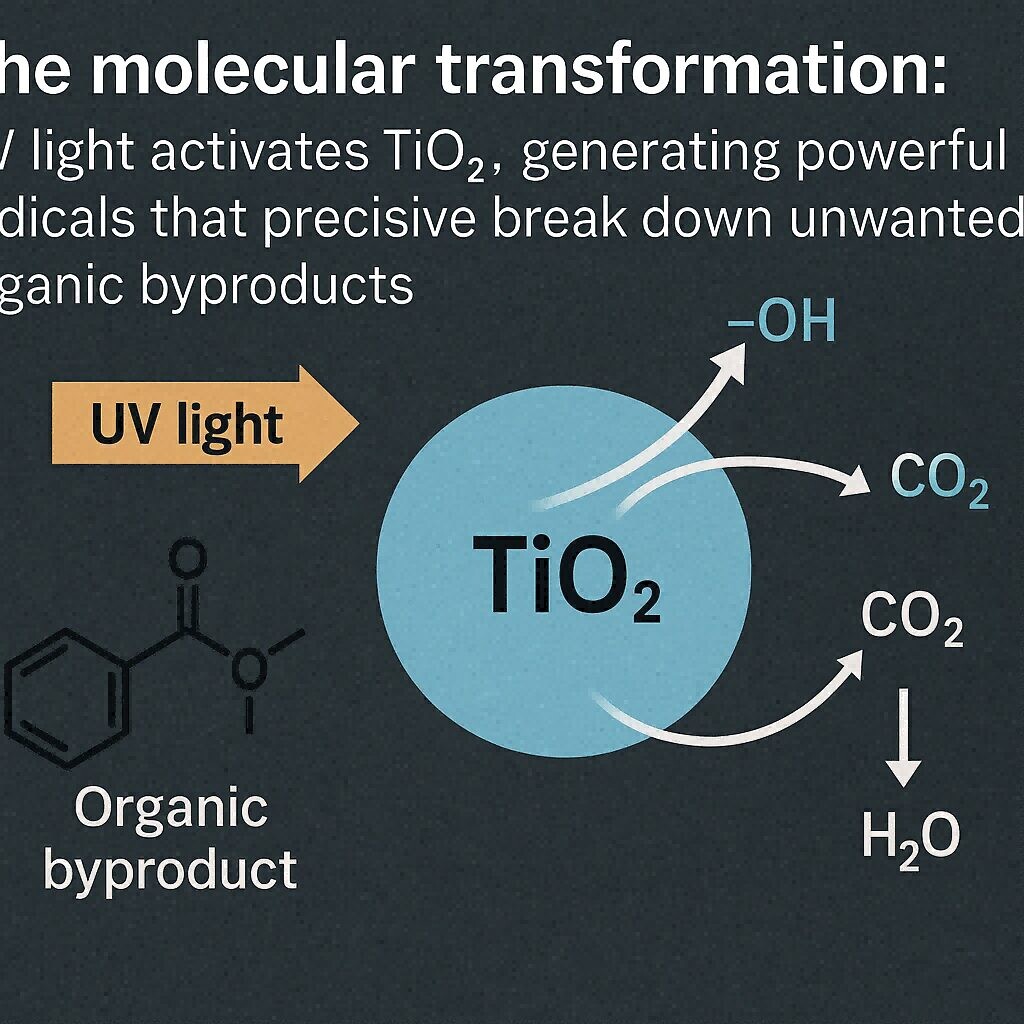

Photocatalysis is a process that uses light energy to accelerate a chemical reaction in the presence of a photocatalyst. The photocatalyst itself remains chemically unchanged at the end of the reaction. For environmental remediation and purification, the most widely studied and effective photocatalyst is Titanium Dioxide (TiO2), particularly in its anatase crystalline form.

(1)Light Absorption:When TiO2 is exposed to UV light (or even visible light if doped or modified), it absorbs photons with energy equal to or greater than its band gap.

(2)Electron-Hole Pair Generation:This absorption excites an electron (e−) from the valence band to the conduction band, leaving behind a positively charged “hole” (h+) in the valence band.

(3)Reactive Species Formation:

(4)Oxidative Degradation:These highly reactive species (hydroxyl radicals, superoxide radicals, etc.) are extremely powerful oxidizing agents. They indiscriminately attack and break down a wide range of organic compounds present in the e-liquid, converting them into simpler, less harmful, or even completely innocuous substances like carbon dioxide (CO2) and water (H2O).

(1)Non-Selective Degradation of Organics:The reactive radicals generated can break down a broad spectrum of organic unwanted byproducts, regardless of their specific chemical structure. This makes it effective against diverse impurities.

(2)Environmental Friendliness:The process typically uses TiO2, which is non-toxic, inexpensive, abundant, and reusable. It does not produce secondary waste streams (unlike some chemical treatments).

(3)Ambient Conditions:Photocatalysis can often occur at room temperature and atmospheric pressure, avoiding the need for harsh chemicals or extreme conditions that could damage desired flavor compounds.

(4)Potential for Continuous Flow Systems:Can be integrated into a continuous production line for on-the-fly purification.

(5)Targeted Removal:While broad, the process can be tuned (e.g., by adjusting UV intensity, reaction time, TiO2 concentration, or by pre-treatment) to selectively target certain classes of compounds.

Molecular transformation: photocatalytic reaction process

Applying photocatalytic degradation to e-liquid flavoring and finished products requires careful engineering and a deep understanding of the interactions involved.

The integration of photocatalytic degradation offers compelling advantages for e-liquid manufacturers aiming for superior product quality:

Pure taste, perfectly presented

Navigating the complexities of photocatalytic degradation and ensuring its safe and effective application for e-liquid specific flavors requires a flavor partner with deep scientific expertise, state-of-the-art analytical capabilities, and an unwavering commitment to quality and safety.

CUIGUAI Flavoring is at the forefront of innovation in e-liquid specific flavors, actively exploring and integrating advanced purification technologies like photocatalytic degradation into its production processes. Their dedicated R&D team meticulously researches the optimal application of this technology to remove unwanted byproducts from flavor concentrates and base ingredients, ensuring the highest standards of purity. By leveraging photocatalytic vape cleaning, CUIGUAI Flavoring aims to deliver electronic liquid essences with unprecedented flavor integrity, reduced harshness, and extended stability, directly translating to a superior user sensory experience. For manufacturers committed to offering the cleanest, safest, and most authentic vape products, CUIGUAI Flavoring provides the technical expertise and innovative solutions to elevate product quality to new heights.

The adoption of photocatalytic degradation marks a significant advancement in the e-liquid industry’s commitment to purity and safety. It represents a proactive step towards mitigating the challenges posed by unwanted byproducts, moving beyond simply masking them to fundamentally removing them.

As scientific understanding of photocatalysis continues to evolve, we can anticipate further refinements in catalyst design, reactor efficiency, and the development of more selective processes. This will pave the way for even more precise byproduct removal without compromising desired flavor integrity. For consumers, this translates to a consistently cleaner, smoother, and more enjoyable vaping experience. For manufacturers, it offers a powerful tool for differentiation, quality assurance, and building a trusted brand reputation in an increasingly scrutinized market. The future of e-liquids is not just about innovation in flavor, but about innovation in purity – illuminated by the power of light.

Photocatalysis Research Laboratory

Keywords: photocatalytic vape cleaning, byproduct removal, unwanted byproducts, flavor degradation, e-liquid purity, titanium dioxide, user sensory experience, advanced purification

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jul 31, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy