From Gene to Flavor

In the intricate world of flavor chemistry, a small group of compounds holds an outsized influence. Esters, with their distinctive sweet, fruity, and floral notes, are the backbone of countless aroma profiles, from a juicy pineapple to a ripe strawberry or a delicate rose. The global demand for these high-impact flavor compounds is immense, yet the traditional methods of producing them are fraught with limitations.

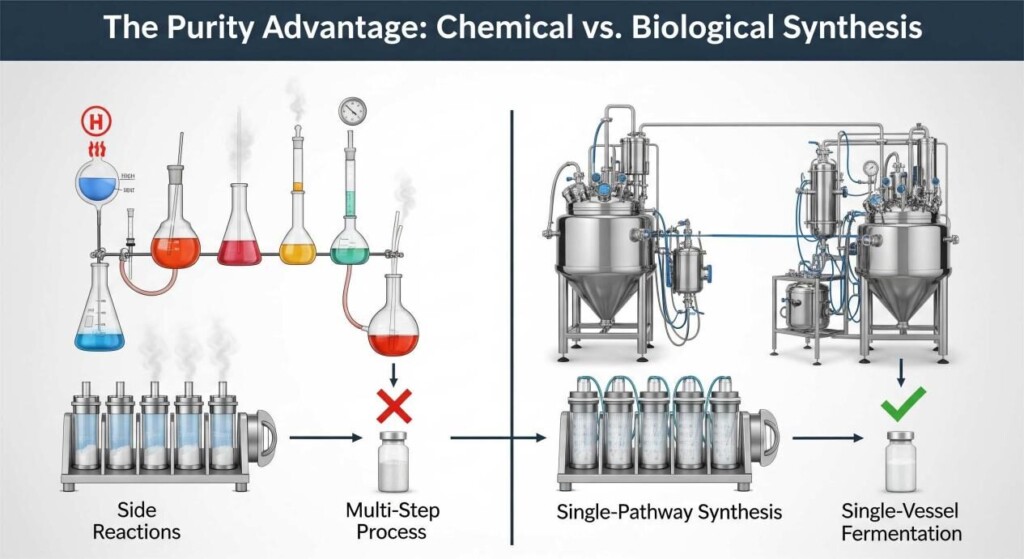

Chemical synthesis, while scalable, can introduce unwanted side-products and impurities that create off-notes. Botanical extraction, while yielding a “natural” product, is often expensive, inconsistent, and environmentally taxing, as it requires vast tracts of land and is susceptible to seasonal and climatic variations. These challenges create a bottleneck for innovation and a constant struggle for consistency in mass production.

Today, a new and transformative paradigm is emerging at the intersection of flavor chemistry and biotechnology: the use of CRISPR-edited yeast to synthesize high-purity esters. This revolutionary approach, born from the fields of synthetic biology and metabolic engineering, offers a pathway to produce flavor compounds with unprecedented consistency, purity, and sustainability. This comprehensive technical guide will delve into the scientific foundations of this technology, explore its practical applications, and analyze its profound implications for the future of the flavor industry.

To appreciate the power of this technology, we must first understand the fundamental science behind it. This is a story of turning a simple microorganism into a high-precision chemical factory.

Esters are naturally occurring compounds formed by the reaction of an alcohol and a carboxylic acid. While they are responsible for the wonderful aromas of fruits and flowers, they are typically present in very low concentrations. For example, a kilogram of strawberries may contain only a few milligrams of the specific esters that give it its characteristic aroma. Extracting these trace amounts is a complex and costly process, often yielding a mixture of compounds rather than a single, high-purity target molecule.

CRISPR-Cas9 is a gene-editing technology that originated as a bacterial immune system. It allows scientists to precisely cut and edit DNA sequences.

Yeast, specifically Saccharomyces cerevisiae (baker’s yeast), is an ideal host organism for this process. It is robust, well-understood, and has a long history of safe use in the food and beverage industries.

Overexpress Precursors: We can insert or upregulate genes that increase the production of the specific alcohol and carboxylic acid needed for our target ester.

Downregulate Competing Pathways: We can “turn off” or downregulate genes that produce competing compounds, thereby diverting the yeast’s energy and resources towards our desired product.

Enhance the Esterase: We can overexpress the gene for the enzyme (an esterase) that catalyzes the final reaction, combining the alcohol and acid to form the ester.

This targeted approach allows us to create a highly efficient “cell factory” that dedicates its resources to producing a single, high-purity aroma compound. A 2023 study in Nature Biotechnology highlighted the successful use of CRISPR to engineer yeast for the high-yield production of flavor compounds, marking a significant advancement in synthetic biology (Reference 1: Nature Biotechnol., 2023, “CRISPR-mediated Metabolic Engineering for High-Yield Flavor Production”).

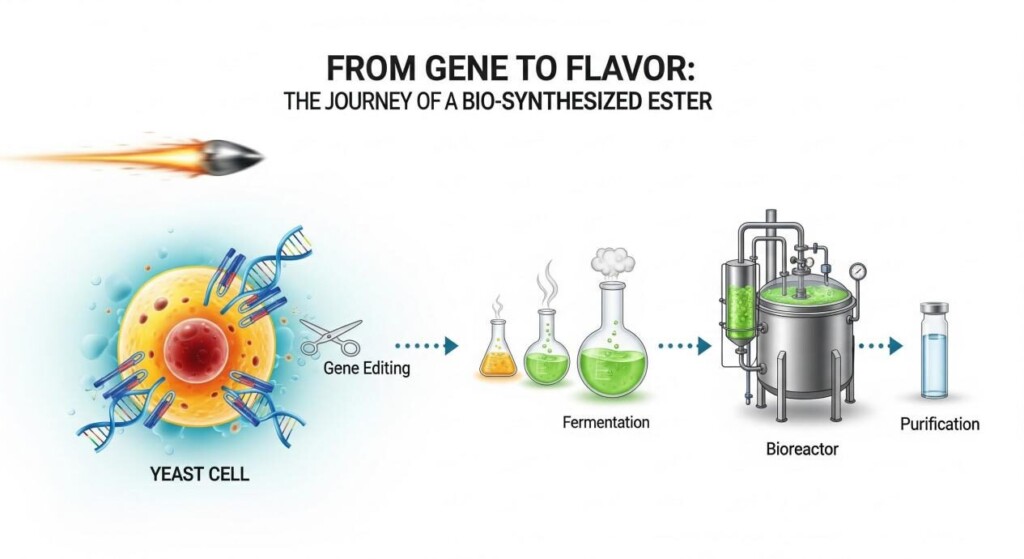

The journey from a gene-edited cell to a final commercial product is a complex but well-defined process that combines molecular biology with large-scale bioprocessing.

The process begins with the selection of a robust yeast strain. We then use a detailed CRISPR protocol to introduce the precise genetic modifications.

The gene-edited yeast strain is then cultivated in a highly controlled environment.

After fermentation, the final ester must be isolated and purified from the complex fermentation broth.

The Purity Advantage

This bio-based approach to flavor production is not just a scientific curiosity; it is a disruptive force with significant commercial and environmental advantages.

Traditional chemical synthesis often produces a mix of stereoisomers or unwanted by-products, which can impart subtle off-notes. The bio-synthesis process, however, is highly specific and produces a single, desired ester without these impurities.

Fermentation is a highly scalable process. Once the initial R&D and pilot-scale validation are complete, the process can be seamlessly scaled to large industrial bioreactors.

The environmental benefits of bio-synthesis are immense. It reduces reliance on petrochemically derived starting materials and minimizes the need for agricultural land used for botanical extraction.

The successful commercialization of this technology requires a strategic approach that addresses regulatory hurdles, public perception, and market dynamics.

Flavor compounds, especially those produced by novel methods, must navigate a complex regulatory landscape.

The term “CRISPR” can raise consumer concerns about genetically engineered organisms. It is crucial for brands to be transparent and to educate the public.

This technology is poised to disrupt the flavor market by providing a new pathway to produce high-purity, consistent, and sustainable flavors.

The New Standard of Purity

The use of CRISPR-edited yeast for the synthesis of high-purity esters is not just a technological breakthrough; it is a fundamental shift in how we think about flavor production. It is a transition from an era of costly, inconsistent, and resource-intensive extraction to an era of precise, scalable, and sustainable bio-manufacture.

By mastering this technology, flavor companies can ensure their products meet the highest standards of purity and consistency, while also contributing to a more sustainable future. For a consumer, this means a better-tasting, more reliable product. For a brand, it means a powerful competitive advantage and a foundation for long-term growth. The future of flavor is here, and it is being built one gene-edited yeast cell at a time.

Keywords: biotech vape flavor, CRISPR aroma compound synthesis

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Sep 16, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy