The pursuit of the ultimate vaping experience is a relentless journey into the frontiers of flavor science. While traditional methods of e-liquid formulation have delivered a vast array of tastes, they often contend with the inherent challenges of flavor complexity, stability, and the desire for truly authentic and targeted sensory interactions. Imagine a world where flavor perception isn’t left to chance, but is precisely engineered through molecular recognition – where specific aroma molecules are “locked in” and released with unprecedented selectivity. This transformative vision is becoming a reality with Molecular Imprinting Technology (MIT), a revolutionary approach poised to redefine how we design, deliver, and experience flavors. This blog post will delve into the intricate science and profound potential of molecular imprinting flavor applications, exploring how these highly selective synthetic receptors pave the way for unparalleled selective aroma binding and a new era of precision in vaping.

Molecular imprinting and fragrance molecules

The human sense of smell, while remarkably sensitive, relies on a vast array of olfactory receptors, each with varying degrees of selectivity. In engineered systems like e-liquids, achieving precise and consistent flavor delivery faces several hurdles:

These challenges highlight the need for a more intelligent approach to flavor management – one that offers molecular-level control and unprecedented specificity.

Molecular Imprinting Technology (MIT) is a fascinating technique that allows for the creation of synthetic polymers with specific recognition sites for a target molecule. It’s akin to creating a molecular “lock” (the imprinted polymer) that perfectly fits a specific “key” (the target flavor molecule).

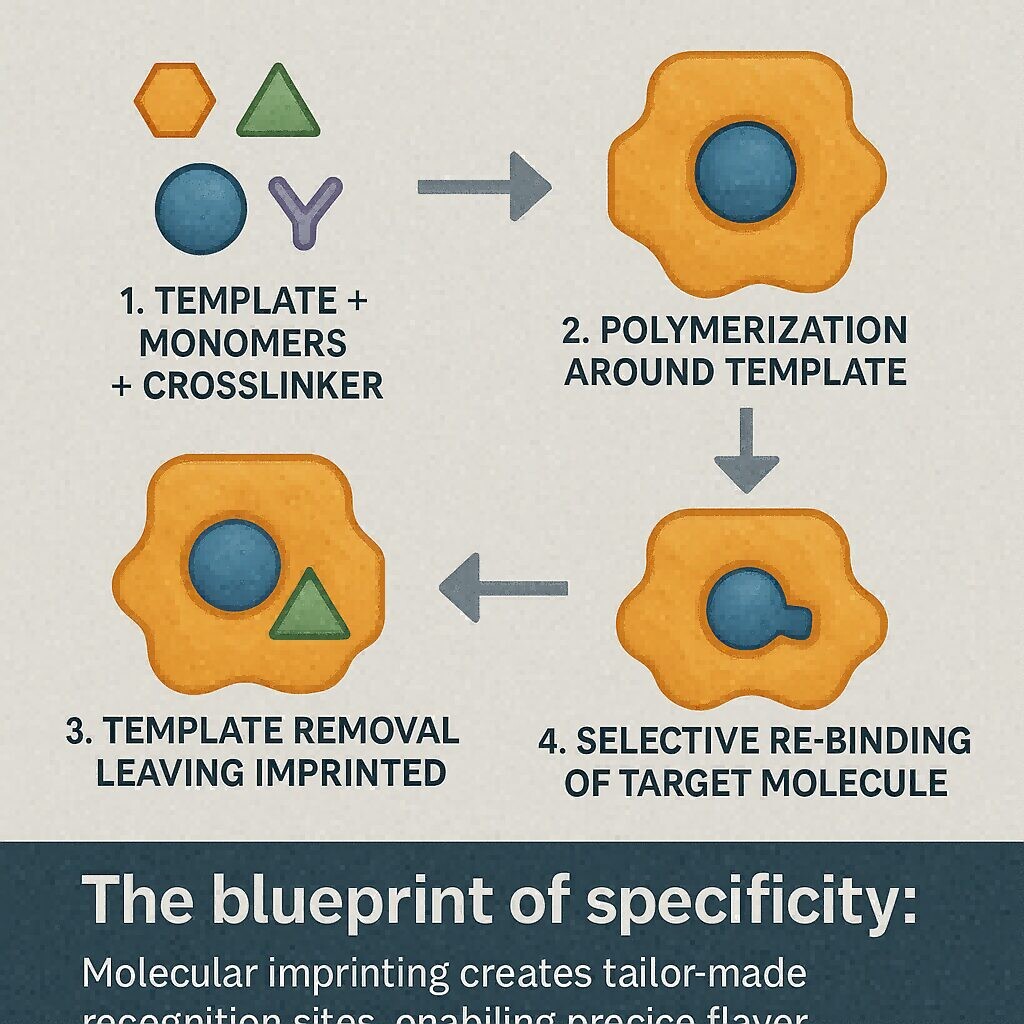

The core principle involves a “template” molecule (the flavor compound we want to selectively bind) and a polymerization process:

(1)Template and Monomers:The chosen flavor molecule (the “template”) is mixed with functional monomers (small molecules that will form the polymer) and a cross-linker (to create a stable, porous polymer network).

(2)Pre-Assembly:The functional monomers arrange themselves around the template molecule through non-covalent interactions (e.g., hydrogen bonding, electrostatic forces, van der Waals forces). This “pre-assembly” step is crucial for creating the specific binding sites.

(3)Polymerization:A polymerization initiator is added, and the monomers polymerize around the template, effectively “freezing” the arrangement and creating a rigid polymeric matrix.

(4)Template Removal:Once the polymerization is complete, the template flavor molecule is removed (e.g., by washing with a suitable solvent), leaving behind highly specific “imprinted” cavities or recognition sites within the polymer structure. These cavities are complementary in shape, size, and chemical functionality to the original template molecule.

The resulting polymer, known as a Molecularly Imprinted Polymer (MIP), can then selectively re-bind the target flavor molecule from a complex mixture, much like an antibody binds to an antigen, but in a synthetic, robust, and often more cost-effective manner.

(1)Shape Complementarity:The imprinted cavities perfectly match the three-dimensional shape of the target flavor molecule.

(2)Chemical Complementarity:The functional groups within the cavity are arranged to form specific chemical interactions (e.g., hydrogen bonds, hydrophobic interactions) with the target molecule.

(3)Specificity over Affinity:While high affinity (strong binding) is important, the true power of MIPs lies in their selectivity – their ability to bind a particular flavor molecule preferentially, even in the presence of similar-looking or higher-concentration competing molecules.

Schematic diagram of the molecular imprinting process

The application of molecular imprinting flavor technology holds immense potential for revolutionizing e-liquid formulation and the vaping experience.

While the potential of molecular imprinting flavor is immense, its application in e-liquids faces several technical hurdles:

1.Safety for Inhalation:The most critical challenge. The MIP polymer matrix itself, and any potential byproducts of its thermal degradation during vaping, must be proven unequivocally safe for inhalation. This requires extensive toxicological studies far beyond food-grade standards.

2.Polymer Design and Synthesis:

(1)E-liquid Compatibility:The MIP must be stable and dispersible within the PG/VG base without clumping, sedimentation, or reacting with other components.

(2)Binding Strength Tunability:Achieving the right binding strength – strong enough to protect the flavor, but weak enough to release it efficiently upon heating.

(3)Scale-Up:Moving from laboratory-scale synthesis to industrial-scale production of high-quality, consistent MIPs is complex.

3.Flavor Integration and Releasability:

(1)Efficient Encapsulation and Release:Ensuring that the template flavor is efficiently imprinted and then quantitatively released upon heating without residual binding.

(2)Multi-Flavor Systems:Designing MIPs for multiple flavor components within a single e-liquid is significantly more complex, requiring either separate MIPs for each flavor or a multi-imprinted polymer.

4.Cost-Effectiveness:The current synthesis of highly specific MIPs can be expensive, which needs to be balanced against the value proposition of enhanced flavor.

Beyond traditional experiences

Leveraging the revolutionary potential of molecular imprinting flavor technology requires a flavor partner with unparalleled scientific expertise, cutting-edge research facilities, and a steadfast commitment to safety and quality.

CUIGUAI Flavoring is actively investing in the forefront of advanced flavor delivery systems, including the exploration and development of molecular imprinting techniques for their e-liquid specific flavors. Their dedicated R&D team is focused on engineering highly selective synthetic receptors designed to capture and precisely release desired aroma compounds, enabling unprecedented selective aroma binding and stability. CUIGUAI Flavoring’s commitment to rigorous safety assessments and pushing the boundaries of flavor science ensures that their future innovations will deliver e-liquids with superior flavor integrity, dynamic release profiles, and an unmatched sensory experience. For manufacturers poised to lead the next generation of precision vaping, CUIGUAI Flavoring offers the expertise and innovative solutions to truly differentiate their products.

The integration of molecular imprinting technology represents a monumental leap forward in e-liquid formulation. It moves beyond passive flavor delivery to an active, intelligent system capable of responding to the vaping environment with hyper-specificity.

This level of control promises:

While the journey from concept to widespread commercial application involves significant research and regulatory navigation, the foundational science of molecular imprinting flavor is clear. It is not just about making flavors taste good; it is about making them taste exactly as intended, exactly when desired, and with an authenticity that has been previously unattainable. The future of vaping flavor is incredibly precise, profoundly authentic, and dynamically responsive.

Perfectly precise molecular imprinting

Keywords: molecular imprinting flavor, selective aroma binding

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jul 26, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy