Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jan 17, 2026

Modern E-Liquid Homogenization Lab

In the contemporary e-liquid market, the margin between a successful premium brand and a struggling startup often comes down to chemical stability and sensory consistency. As specialized flavoring manufacturers, we recognize that the “art” of flavor creation is increasingly becoming the “science” of fluid dynamics. One of the most critical, yet frequently misunderstood, phases of production is homogenization.

For the uninitiated, mixing might seem like a simple mechanical task—stirring ingredients until they appear uniform. However, at the molecular level, an e-liquid is a chaotic battlefield. Propylene Glycol (PG), Vegetable Glycerin (VG), nicotine, and a complex array of flavor volatiles (esters, aldehydes, terpenes, and ketones) all possess varying polarities, densities, and solubilities.

Without advanced homogenization, these components inevitably succumb to the laws of thermodynamics, leading to flavor separation, “peppery” nicotine hotspots, and product degradation. Today, the industry leaders are choosing between two dominant technologies: High-Shear Mixing and Ultrasonic Homogenization.

This article provides an exhaustive, 3,000-word technical deep-dive into these two methodologies, comparing their physics, operational efficiencies, and their specific impacts on the long-term stability of flavor emulsions.

To understand why we need high-energy mixing, we must first examine the challenges inherent in the e-liquid matrix.

Most high-impact flavorings are derived from essential oils or organic compounds that are naturally hydrophobic. When these are introduced into a high-VG (Vegetable Glycerin) base, they do not naturally dissolve. VG is a trihydroxy alcohol; it is thick, highly polar, and resistant to low-energy mixing.

When you stir these together, you aren’t creating a solution; you are creating a coarse emulsion. Over time, the tiny droplets of flavor oil will find each other, merge (coalesce), and rise to the top or sink to the bottom. This is known as “phase separation,” and it is the primary reason for “shake well before use” labels—a label that no premium manufacturer wants to rely on.

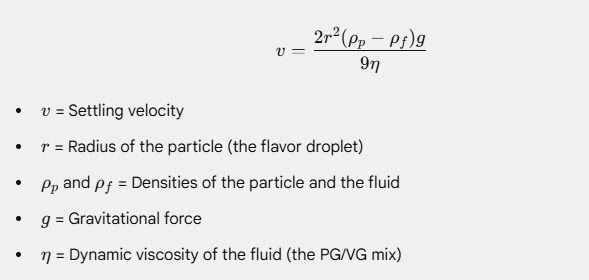

In fluid dynamics, the stability of a suspension is governed by Stokes’ Law. This formula determines how fast a particle will settle or rise in a fluid:

The key takeaway for a manufacturer is that the settling velocity is proportional to the square of the radius (r2). If you reduce the size of the flavor droplet by a factor of 10, you reduce the speed of separation by a factor of 100. If you can move from the micrometer scale to the nanometer scale, the Brownian motion (the random movement of molecules) becomes stronger than gravity, and the emulsion becomes “infinitely” stable.

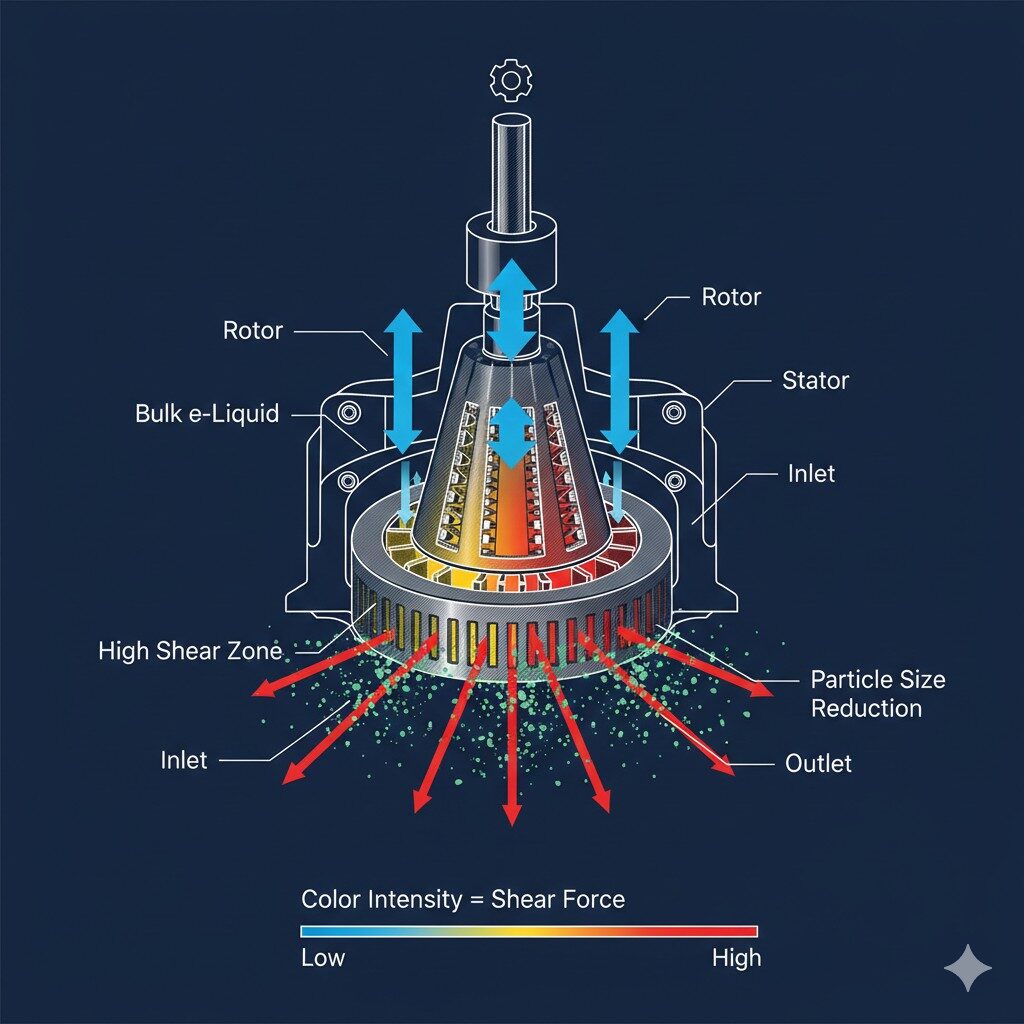

High-shear mixing, specifically using Rotor-Stator technology, has been the backbone of the pharmaceutical and food industries for decades. In the context of e-liquid, it represents the first major step up from standard propeller agitation.

A high-shear mixer does not just stir; it mechanically tears the liquid apart. The system consists of a high-speed rotor spinning inside a stationary stator. The rotor blades spin at tip speeds often exceeding 20 meters per second.

The process follows a four-stage cycle:

According to the Encyclopedia of Chemical Processing, high-shear mixers are the most efficient tools for reducing the apparent viscosity of non-Newtonian fluids during the mixing process [1]. Since VG is a highly viscous fluid, the “shear-thinning” effect of a high-shear mixer allows the flavorings to integrate much more rapidly than they would in a low-energy environment.

While high-shear is excellent for large batches, it typically reaches a “limit of reduction.” Most industrial rotor-stator mixers can only reduce particle sizes to approximately 2 to 5 microns. While this is a significant improvement over hand-mixing, it is still technically a “macro-emulsion.” Over a shelf life of 18–24 months, these particles may still eventually coalesce.

High-Shear Rotor-Stator Diagram

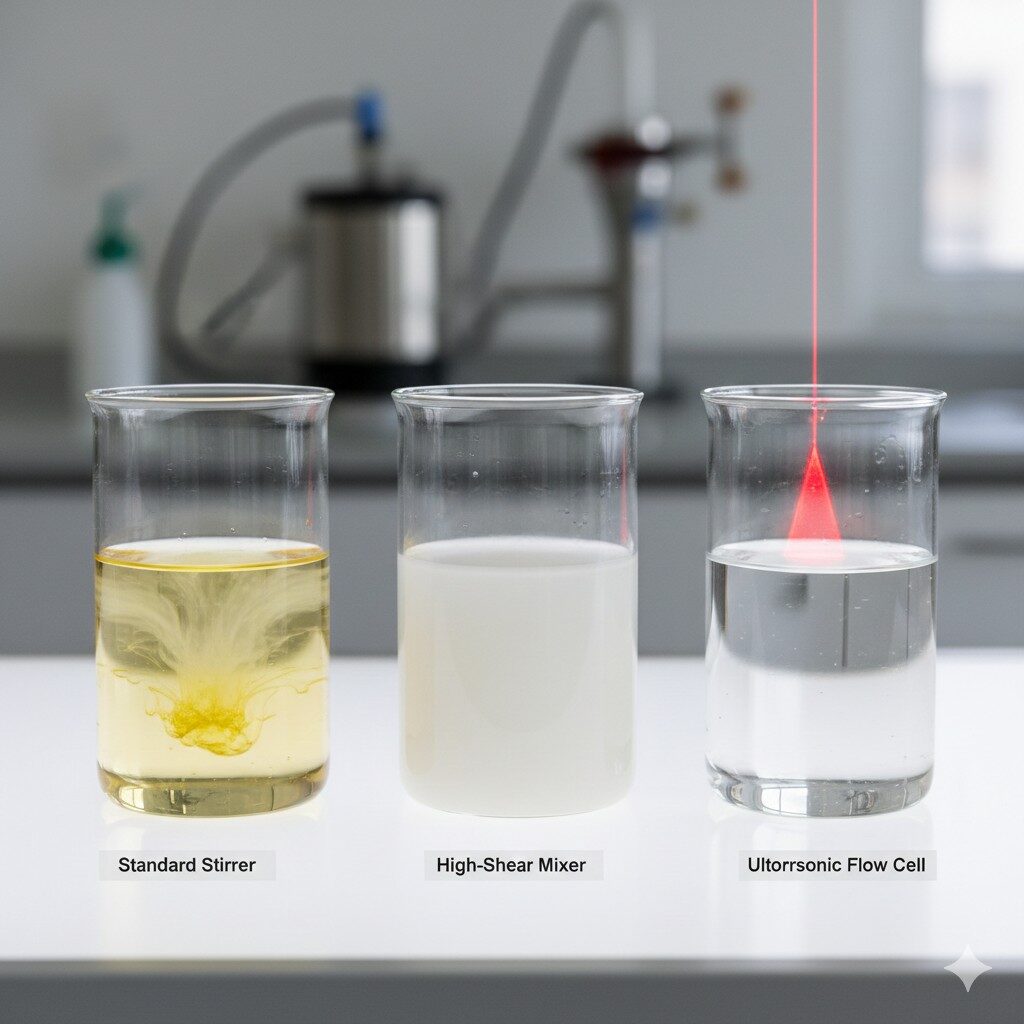

As the vaping industry moves toward more complex, “natural” extract-based flavorings and CBD-infused liquids, the demand for even smaller particle sizes has led many manufacturers to Ultrasonic Homogenization (Sonication).

Unlike high-shear mixing, which uses mechanical contact and velocity, ultrasonic mixing uses sound waves. An ultrasonic processor (sonicator) converts electrical energy into high-frequency mechanical vibrations (typically 20,000 cycles per second, or 20 kHz).

These vibrations are transmitted into the e-liquid through a titanium probe (horn). This creates a phenomenon known as acoustic cavitation:

The collapse of these bubbles is one of the most energetic events in fluid chemistry. At the point of collapse, localized temperatures can reach 5,000°C and pressures can reach 1,000 atmospheres. However, because this happens at a microscopic scale for a fraction of a second, the bulk temperature of the e-liquid stays manageable. These “micro-jets” of liquid act like tiny hammers, smashing flavor oil droplets down into the nano-range (10nm to 200nm).

In a nano-emulsion produced by ultrasonics:

As noted in a 2021 study on ultrasonic processing published in Frontiers in Chemistry, sonication can achieve a degree of emulsion stability that mechanical mixing cannot replicate, particularly when working with complex organic esters [2].

Choosing between these two technologies requires a balance of production volume and product quality goals.

Heat is the enemy of flavor. Many delicate top notes in e-liquids (like strawberry or citrus) are “heat-labile,” meaning they break down when exposed to high temperatures.

E-Liquid Mixing Methods Comparison

Neither high-shear nor ultrasonics can create a permanent emulsion without the correct chemistry. This is where the expertise of a specialized flavoring manufacturer becomes indispensable.

Most flavor concentrates come pre-diluted in PG. PG acts as a “coupling agent.” It is polar enough to mix with VG but organic enough to dissolve flavor esters. However, if a flavor profile is particularly heavy in oils (like a “Lemon Oil” or “Orange Creamsicle”), the PG may not be enough.

In these cases, we must consider the HLB of the system. We often utilize food-grade, vape-safe surfactants like Polysorbate 20 or Vegetable-derived Lecithin to lower the interfacial tension between the oil droplets and the VG base.

The homogenization method dictates how these surfactants behave:

The Journal of Dispersion Science and Technology highlights that the synergy between ultrasonic energy and surfactant concentration is the most critical factor in preventing “Ostwald Ripening”—the process where small droplets merge into larger ones over time [3].

To help our clients navigate these choices, we look at specific product categories.

For a standard fruit-flavored e-liquid using synthetic esters, High-Shear Mixing is almost always the correct choice. The ingredients are relatively compatible, and the goal is high-volume efficiency. A high-shear cycle of 15–20 minutes at 10,000 RPM will produce a stable, high-quality product that will stay uniform for the duration of its shelf life.

If you are formulating a premium line using natural citrus oils, lavender extracts, or mint oils, Ultrasonic Homogenization is superior. Natural oils have a much higher tendency to separate. Sonication ensures these oils are reduced to a nano-scale, preventing the “oil ring” that often forms at the neck of the bottle in organic products.

Nicotine salts often require a lower pH, which can affect the stability of certain flavor emulsions. In these delicate chemical environments, the “gentle” but thorough nano-dispersion provided by ultrasonics can prevent the flavor from “clumping” with the nicotine salts, resulting in a more consistent throat hit and flavor delivery.

How do you know if your mixing process worked? At our laboratory, we use several analytical techniques to verify that our flavorings are perfectly integrated for our clients.

DLS is the gold standard for measuring nano-particles. By shining a laser through a sample and measuring the “shimmer” (fluctuations in light intensity), we can determine the exact particle size distribution. A “unimodal” peak at 150nm indicates a perfect ultrasonic emulsion. A wide, “multimodal” peak suggests that the emulsion will likely separate.

We can simulate six months of shelf-time in ten minutes by placing the e-liquid in a high-speed centrifuge. If the liquid shows any sign of layering or “creaming” after being subjected to 5,000 Gs, the homogenization process needs adjustment.

For high-shear batches, we use digital microscopy to ensure that no flavor “globules” larger than 5 microns remain. This ensures a smooth vaping experience without the risk of the user inhaling concentrated bursts of flavoring or nicotine.

As specified by various international standards for emulsion stability (such as those outlined by the ISO), consistent particle size is the most reliable predictor of chemical longevity [4].

The global regulatory environment (PMTA in the USA, TPD in Europe) is increasingly focused on “Product Consistency.” Regulators want to ensure that the 1,000th bottle off the line is identical to the 1st bottle.

Poor homogenization is a major cause of batch-to-batch variation. If your nicotine isn’t perfectly homogenized, one bottle might contain 3mg/mL while another contains 6mg/mL. This is a fast track to a regulatory recall.

The future of e-liquid manufacturing lies in automated homogenization. We are seeing the integration of sensors that measure viscosity and particle size in real-time. If the system detects that a batch hasn’t reached the target particle size, it automatically increases the shear speed or ultrasonic amplitude.

By investing in these technologies today, manufacturers are not just improving their flavor—they are “future-proofing” their brands against tightening safety standards.

The transition from a hobbyist mixer to a professional manufacturer is marked by a respect for the complexity of the e-liquid matrix. Homogenization is not a “set it and forget it” step; it is a critical engineering process that defines the quality, safety, and longevity of your product.

High-shear mixing remains the essential tool for scale and efficiency, providing the mechanical power needed to process thousands of liters of VG-heavy liquid. Ultrasonic homogenization, meanwhile, represents the cutting edge of flavor science, offering a level of stability and clarity that was previously thought impossible.

At CUIGUAI Flavor, we specialize in creating flavor concentrates that are optimized for these high-energy environments. We understand the molecular structure of our esters and how they respond to both mechanical shear and acoustic cavitation. When you partner with us, you aren’t just buying a “flavor”; you are buying a chemically engineered solution designed to stay stable from the laboratory to the consumer’s tank.

Precision Nano-Emulsification Macro

Are you experiencing flavor separation or inconsistent batches? Our technical team is available for deep-dive consultations on mixing room optimization and flavor stability.

Contact CUIGUAI Flavor for:

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy