Electronic Olfactory Devices and Data Analysis

In the intensely competitive world of flavor production, consistency and unwavering quality are paramount. For manufacturers, especially in sensitive sectors like e-liquids where consumer satisfaction is inextricably linked to sensory experience, the ability to precisely define, reproduce, and quality-check flavor profiles is not just an advantage—it’s a fundamental requirement. Traditional sensory panels, while invaluable, are inherently subjective, prone to fatigue, and cannot provide the rapid, objective, and high-throughput analysis demanded by modern production lines.

Enter the Electronic Nose (E-Nose): a revolutionary analytical instrument designed to mimic the human olfactory system. By “smelling” and recognizing complex aroma patterns, E-Noses are transforming Quality Control (QC) in flavor production. These intelligent systems offer unprecedented capabilities for rapid, objective, and consistent flavor profiling, enabling manufacturers to ensure every batch of flavor concentrate meets stringent sensory specifications, detect subtle deviations, and maintain unparalleled product integrity.

This article delves into the technical intricacies of using Electronic Noses for QC in flavor production, particularly highlighting their impact on the e-liquid industry. We will explore the underlying principles of E-Nose technology, its key applications in flavor QC, the immense benefits it offers, and how this cutting-edge tool is poised to redefine standards for aroma quality and consistency.

The human nose, while incredibly sensitive and complex, has inherent limitations when it comes to industrial-scale quality control:

These limitations underscore the need for an objective, rapid, and repeatable analytical solution.

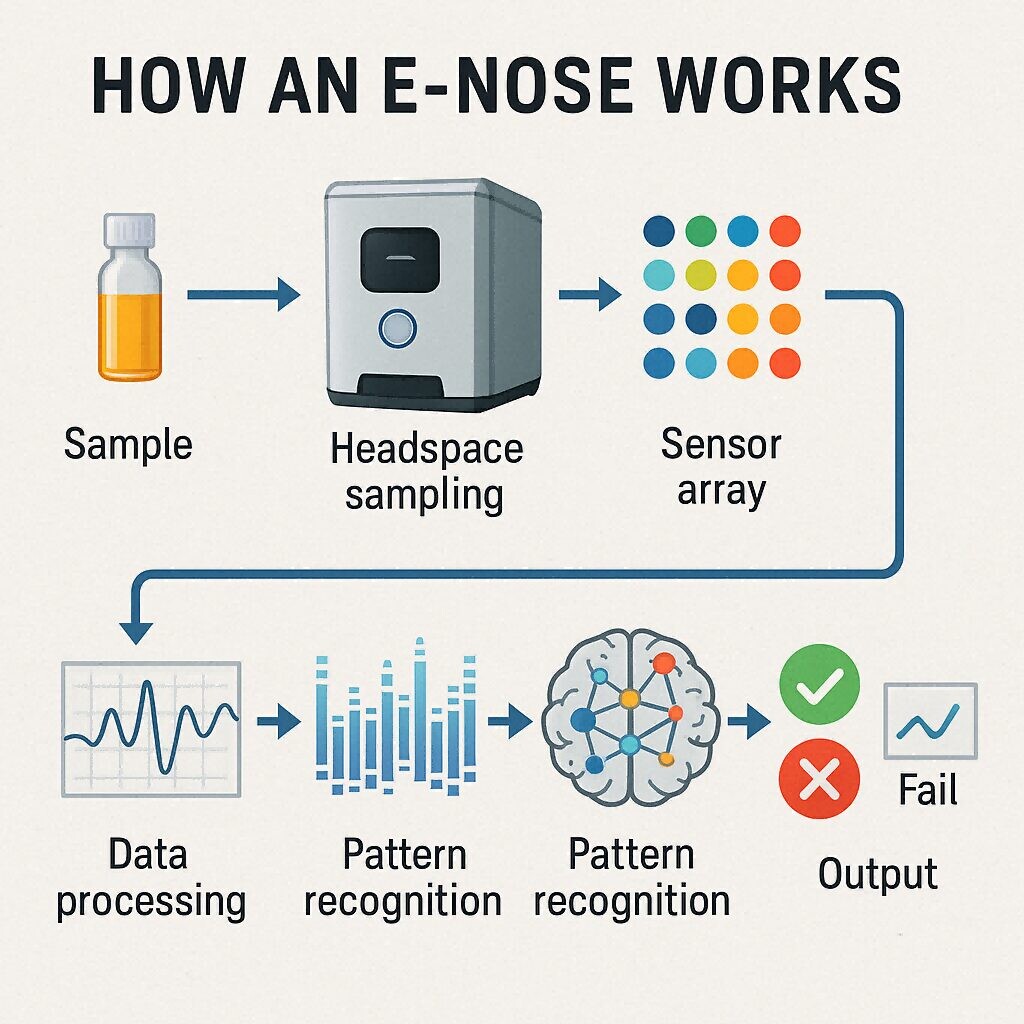

An Electronic Nose is essentially an array of chemical sensors, coupled with a pattern recognition system, designed to detect and identify complex odors and volatile organic compounds (VOCs).

1.Sensor Array:The core of an E-Nose is its sensor array, comprising multiple individual sensors (typically 10-30 or more). Each sensor is designed to respond to different classes of volatile chemicals (e.g., alcohols, esters, ketones, aldehydes, sulfur compounds) or specific functional groups. Common sensor technologies include:

2.Sampling System:A sophisticated sampling system introduces the headspace (vapor phase) of the sample to the sensor array. This typically involves a purge-and-trap mechanism or direct injection. The sample is often heated to volatilize aroma compounds.

3.Signal Acquisition:As VOCs interact with the sensors, each sensor generates an electrical signal (e.g., change in resistance, capacitance, or frequency) proportional to the concentration and type of VOCs present.

4.Data Processing & Pattern Recognition:The raw signals from the entire sensor array create a multi-dimensional data “fingerprint” for that specific aroma. This data is then fed into a powerful pattern recognition system (often using Artificial Neural Networks (ANNs), Principal Component Analysis (PCA), Support Vector Machines (SVMs), or other machine learning algorithms).

5.Training Phase:Before use, the E-Nose is “trained” with a library of known aroma profiles (e.g., acceptable flavor batches, known off-notes, different flavor variants). The machine learning algorithm “learns” to differentiate between these patterns.

6.Identification/Classification:In the operational phase, when a new sample is introduced, its aroma fingerprint is compared to the learned library. The E-Nose can then:

Electronic Nose Workflow Diagram

The E-Nose is a transformative tool for various aspects of quality control in flavor manufacturing, particularly relevant for the stringent demands of e-liquid production.

Electronic Nose Devices in Quality Inspection

The adoption of Electronic Nose technology marks a pivotal moment in the evolution of flavor quality control. As artificial intelligence and sensor technologies continue to advance, E-Noses will become even more sophisticated, capable of even more nuanced aroma differentiation and predictive analysis.

Manufacturers who embrace this technological frontier and forge strong partnerships with pioneering flavor houses like CUIGUAI Flavoring will be uniquely positioned to:

The Future of Intelligent Analysis and Precision Flavor Creation

In conclusion, the strategic implementation of Electronic Noses for quality control is a transformative leap in flavor production, especially for the demanding e-liquid sector. By bringing unparalleled objectivity, speed, and precision to aroma profiling, E-Noses are setting new benchmarks for consistency and quality. This cutting-edge technology, championed by forward-thinking partners like CUIGUAI Flavoring, is not just about detecting off-notes—it’s about ensuring every single flavor compound contributes perfectly to a harmonious, consistent, and ultimately unforgettable vaping experience.

Keywords: electronic nose vape QC, aroma fingerprinting, flavor quality control, e-liquid flavor analysis, objective flavor assessment, sensory science flavor, CUIGUAI Flavoring

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Aug 06, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy