Estimated reading time: 15–20 minutes

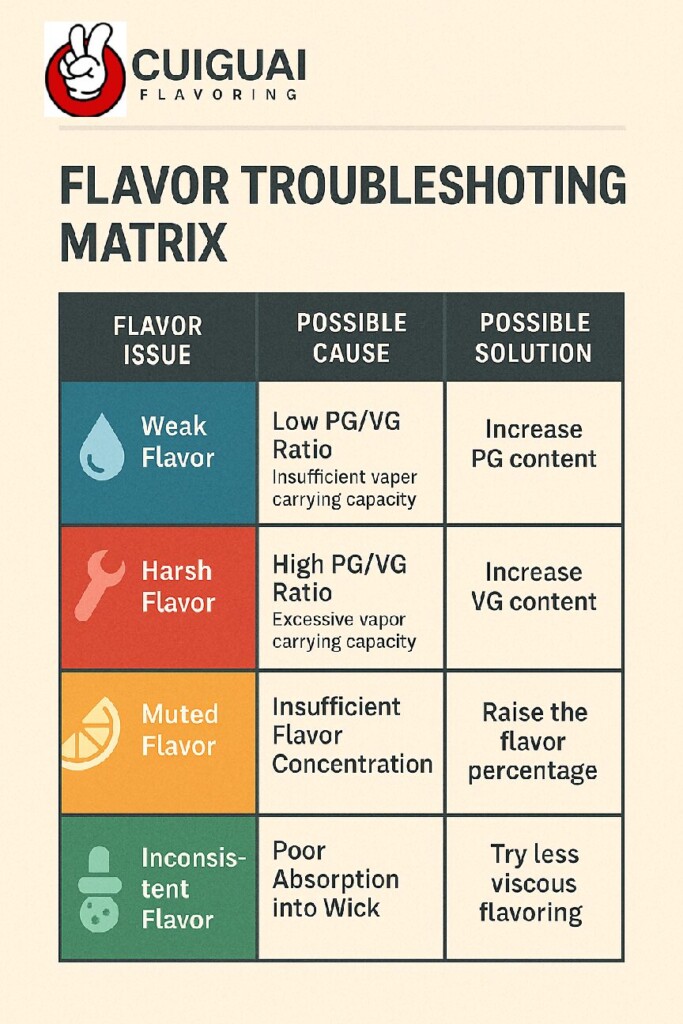

You’ve chosen a high-quality flavoring, tested the ratio, optimized your device settings, and still, the result is underwhelming. The fruit notes are dull. The dessert profile is muted. The “pop” you expected never happens.

The problem may not be your flavoring—it could be your carrier solvent.

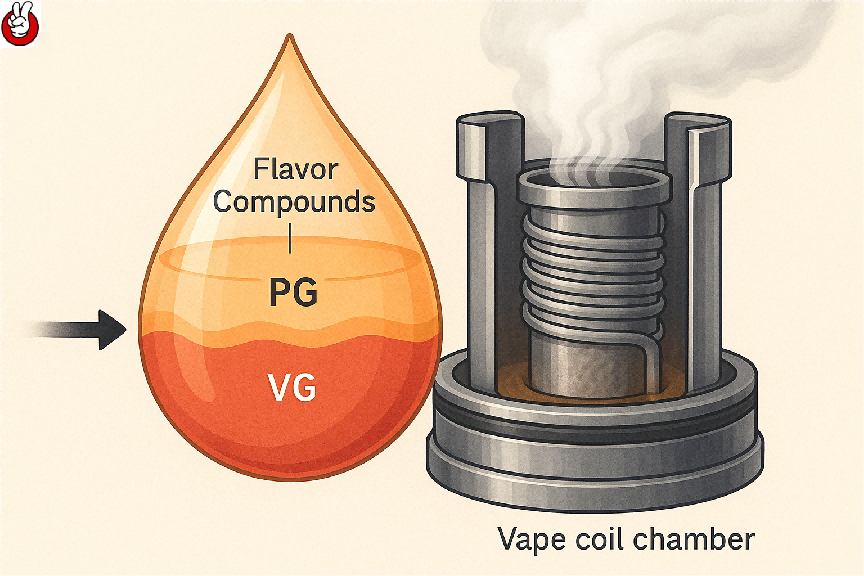

In e-liquid formulation, carrier solvents like Propylene Glycol (PG), Vegetable Glycerin (VG), and their derivatives don’t just act as diluents. They play a central role in:

This article explores how and why carrier solvents affect flavor delivery, highlights critical mistakes formulators make, and guides you to unlock the full potential of your flavor system.

Carrier solvents are the liquid bases used to dissolve flavoring compounds and nicotine. In most e-liquids, this base is composed primarily of:

Each carrier exhibits unique physicochemical properties that determine how flavors are delivered to the user’s palate.

Flavor compounds vary in their polarity. Solvents must match this to solubilize flavor ingredients effectively:

| Solvent | Polarity Index | Best For |

| PG | ~4.3 | Esters, aldehydes, alcohols (fruity, floral notes) |

| VG | ~1.2 | Base notes (sweet, creamy) |

| Ethanol | ~5.2 | Volatile top notes (citrus, mint) |

A mismatch can cause flavor components to separate or degrade, leading to dull taste or inconsistent vaping experience.

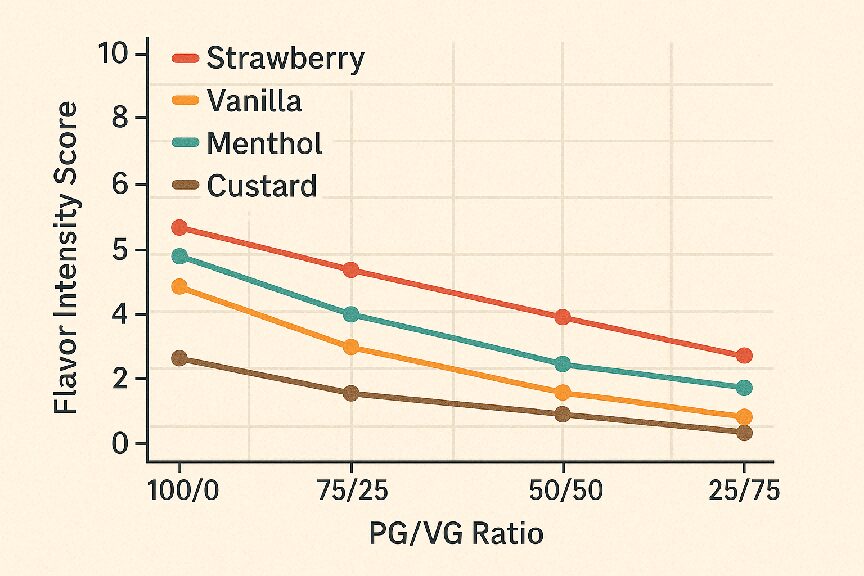

The traditional 50/50 PG/VG blend is a compromise, not a gold standard. Its popularity stems from early hardware limitations rather than formulation science.

Different flavors require different solvent environments. For example:

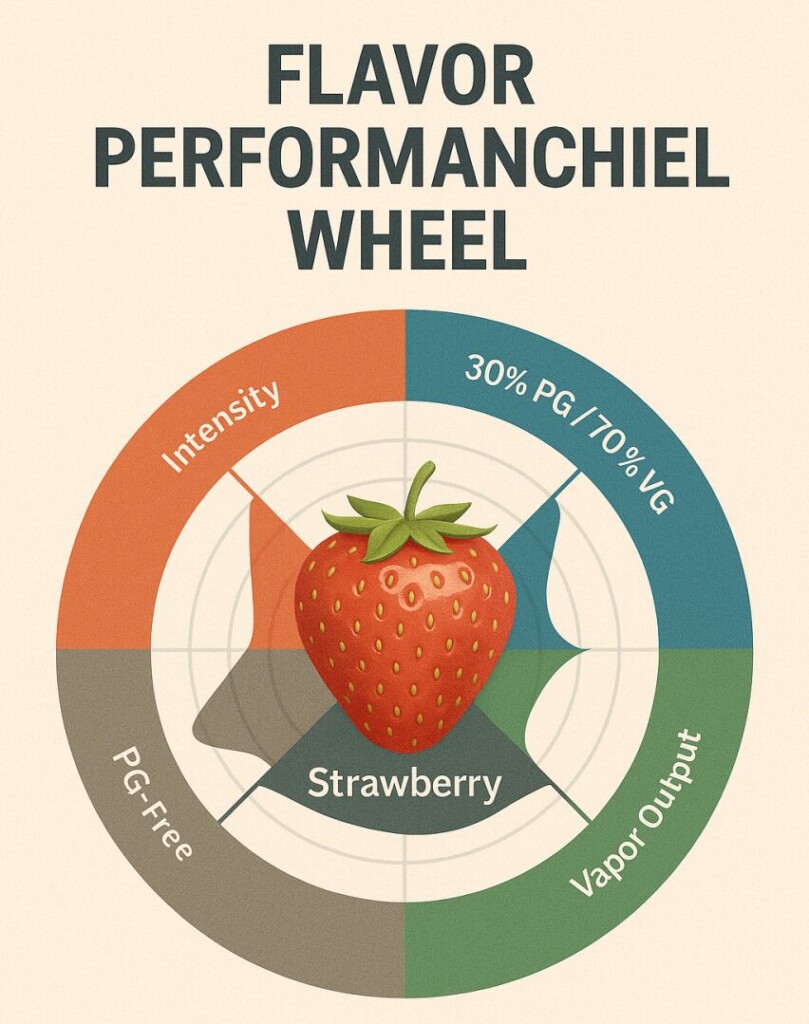

If your strawberry custard tastes flat, it may be because the custard base sits fine in VG, but the strawberry ester needs more PG to volatilize effectively.

VG’s high viscosity and low volatility reduce the rate at which flavor molecules evaporate during coil heating. This can:

While PG offers superior flavor carry, it can:

Some molecules interact with solvents in ways that suppress flavor release. For instance:

| Flavor Type | Ideal PG/VG | Notes |

| Fruity | 60/40 PG/VG | Enhance high-note esters |

| Dessert | 40/60 PG/VG | Rounder mouthfeel with co-solvents |

| Tobacco | 50/50 PG/VG | Balanced delivery with natural extracts |

| Mint/Menthol | 70/30 PG/VG | For fast volatility and freshness |

Rather than defaulting to 50/50, use analytical testing (GC-MS, sensory panels) to determine which flavor carrier base best suits your formulation.

Used in trace amounts (0.1–3%), ethanol can help release top notes in citrus, floral, or herbal flavors. Too much, however, leads to throat irritation or off-odors.

Triacetin offers good solubility for nicotine and alkaloids and acts as a flavor stabilizer in complex tobacco formulations. Its downside? Reduced vapor output and potential buildup in coils.

Medium-chain triglycerides are used in CBD and delta-8 vapes but should be avoided in nicotine-based products due to lipid inhalation risks.

Over time, flavor molecules can:

VG-heavy formulas tend to linger in cotton wicks, absorbing and muting delicate flavor notes—especially problematic in refillable systems.

Tip: Design your base to minimize molecular bonding with wick and coil materials.

If you’re struggling with muted flavor profiles despite using quality ingredients, it’s time to consider flavorings engineered specifically for optimized carrier systems.

CUIGUAI Flavoring offers a specialized range of e-liquid flavors designed with carrier compatibility in mind. Each formula is tested for:

This ensures that what you taste in the lab, you also experience in the tank.

Carrier solvents are often the most overlooked component in e-liquid formulation. Yet they influence every stage of flavor delivery—from solubility and vaporization to mouthfeel and aftertaste.

If your flavors are falling flat, don’t just switch brands or tweak wattage—rethink your base.

Keywords:

PG VG solvent effect, flavor carrier base, e-liquid absorption

muted vape flavor, VG flavor suppression, e-liquid solvent science, flavor volatility, coil retention

Article author: Toby Zhu

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy