Cross-sectional of vapor

In the world of vaping, flavor is everything. Yet, many users—DIY enthusiasts and seasoned flavor manufacturers alike—underestimate how drastically hardware components like coils and cotton affect the flavor profile. This phenomenon, known as the Flavor Filter Effect, plays a critical role in how end users perceive taste, aroma, and throat hit. Understanding the mechanics behind it isn’t just useful—it’s essential for both product developers and experienced vapers who demand consistency.

In this in-depth technical blog, we break down how coil resistance, metal types, wick material, saturation rate, and even puff duration alter what a consumer actually tastes—versus what was originally formulated. We also provide insight into optimizing formulations for better compatibility with diverse hardware setups, and highlight CUIGUAI Flavoring’s advanced flavor concentrates that are precision-engineered for modern coils and wicking materials.

Flavor perception is a complex phenomenon—chemically precise yet physically filtered. Manufacturers can develop brilliant profiles, but those compounds are always mediated by the hardware. The device becomes a secondary “ingredient” in every puff.

This blog is driven by a core question:

“Is the flavor the user tastes the same as the one that was formulated?”

For many vape users and brands, the answer is no. Understanding why—and how to fix it—begins with the coil.

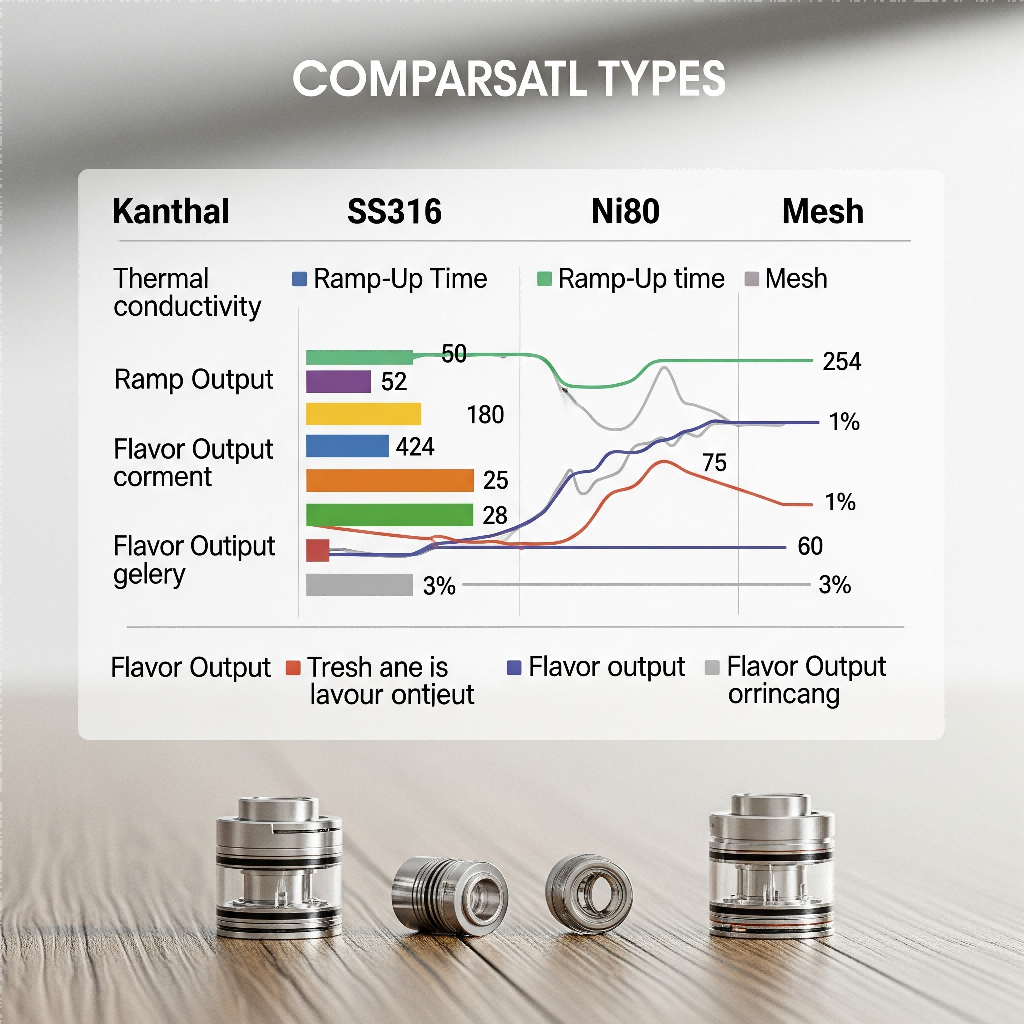

Comparsatl Types

Coil resistance affects how fast and how hot the element gets. Lower-resistance coils heat up faster and to higher temps, but this can result in:

Mesh coils, for example, offer a larger surface area which enhances vaporization but can mute subtle top notes by over-aerosolizing them.

The metal used (Kanthal vs. Stainless Steel vs. Nickel) changes the heat curve:

Insight: If your flavor tastes great in SS but burnt in Ni80, the issue is not the flavor—it’s the delivery environment.

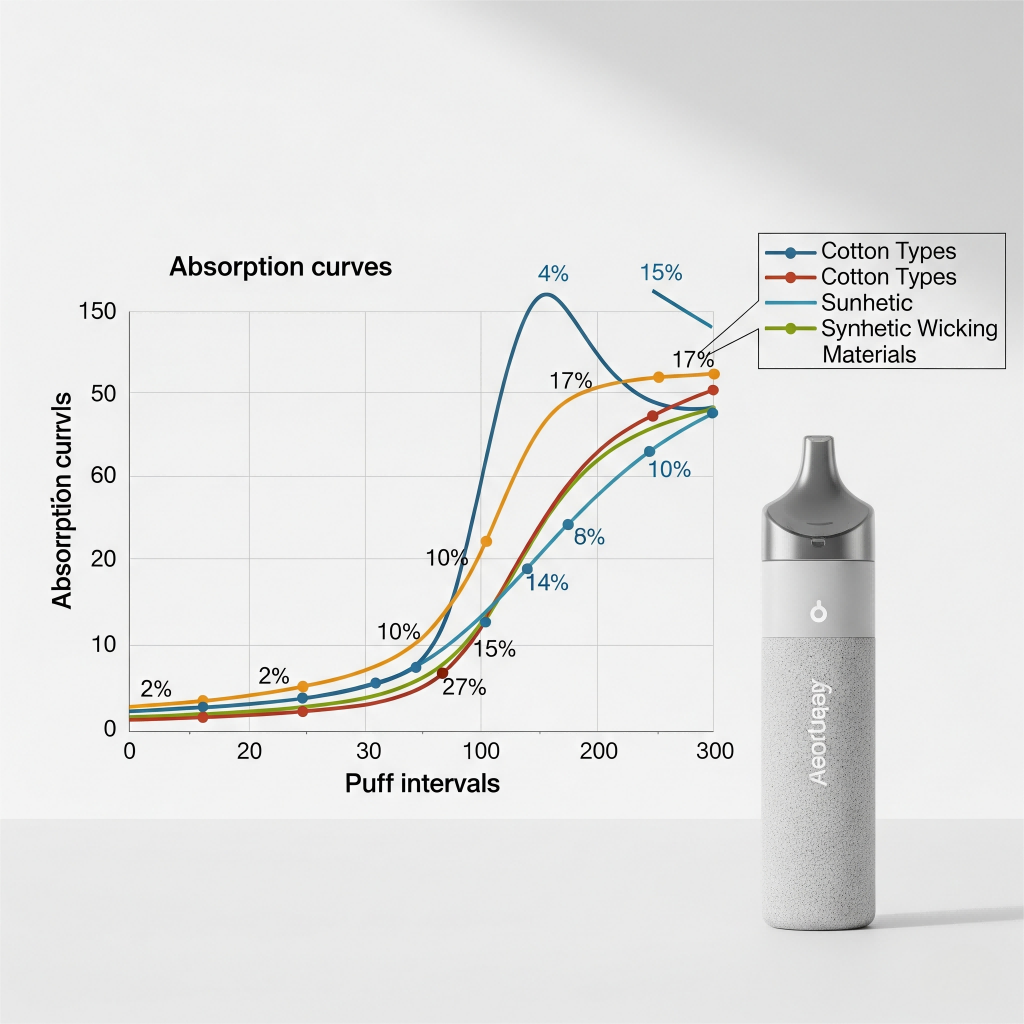

Absorption curve of different cotton types vs. synthetic wicking

Cotton doesn’t just absorb e-liquid—it absorbs selectively. Compounds like vanillin, menthol, or esters can saturate differently due to molecular weight and hydrophobicity.

Cotton acts like a flavor memory card. Once a flavor compound binds within the wick, it may persist across refills—altering the taste of the next juice. This is especially problematic for:

High wattage can char the cotton, introducing carbonized bitterness. Even high-quality flavor formulations cannot overcome this kind of hardware distortion.

Flowchart stages from e-liquid formulation to user inhalation.

This term refers to the sum of interactions between:

It explains why:

How a user vapes affects how flavor compounds volatilize. Here’s how:

| Variable | Impact on Flavor |

| Wattage | Higher wattage = more flavor, but also more compound degradation |

| Puff Duration | Long puffs favor base notes; short puffs emphasize top notes |

| Airflow | Open airflow cools vapor; restrictiveness amplifies throat hit |

| Temperature Control | Enables fine tuning for sensitive profiles (e.g., herbal or citrus-based flavors) |

Pro Insight: If a citrus flavor starts tasting metallic, it’s likely being “burned” by either excessive coil temp or prolonged airflow exposure.

Comparison of blind sensory panel tests

For professional flavor houses, consistency testing is critical. Some of the best practices include:

Developers can optimize formulas for cross-device consistency by:

CUIGUAI Flavoring, a leader in electronic liquid aroma technology, has developed a specialized line of vape concentrates designed to maintain integrity across:

These flavors are crafted with:

Whether you’re creating a menthol-botanical blend or a dessert-tobacco profile, CUIGUAI Flavoring ensures your flavor remains true from bottle to cloud.

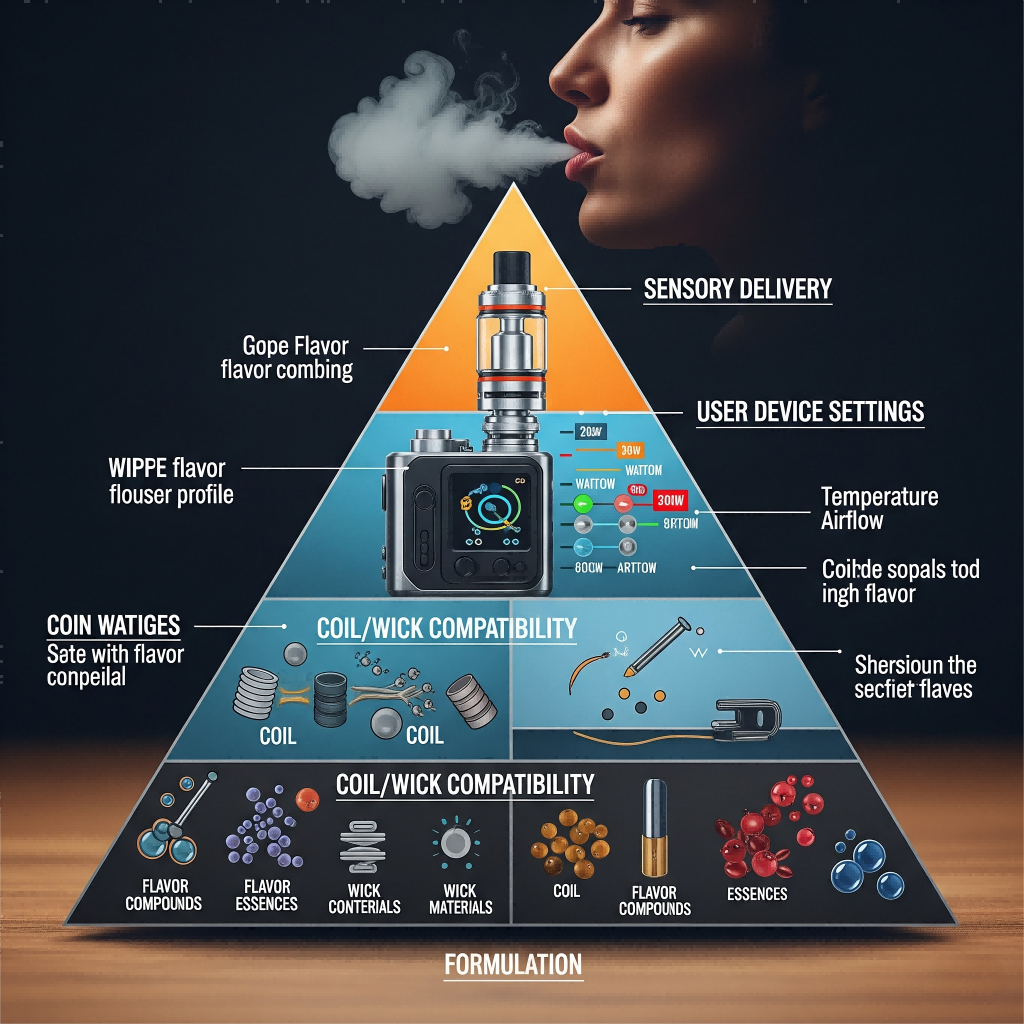

Pyramid showing levels of flavor control

Flavor is not just about what’s in the bottle—it’s about what survives the trip to the user’s palate. As we’ve seen, coils and cotton are not passive carriers. They’re active filters, amplifiers, and in some cases, mutators of flavor compounds.

By understanding the full lifecycle of flavor—from molecular profile to thermal release—developers and manufacturers can close the gap between intended taste and experienced taste. With innovations like those from CUIGUAI Flavoring, the future of consistent, high-fidelity flavor is not only possible—it’s already here.

Keywords: coil effect on flavor, cotton absorption vape, device vs flavor delivery

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 25, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy