Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 14, 2025

E-Liquid Lab Analysis

In the modern vaping industry, flavorings are far more than sensory enhancers—they are scientific, regulatory, and ethical cornerstones. As vaping products face unprecedented scrutiny from global health authorities, the inclusion and documentation of flavorings in Premarket Tobacco Product Applications (PMTA) have become decisive for market authorization.

In the United States, the PMTA process—administered by the U.S. Food and Drug Administration (FDA)—requires manufacturers to demonstrate that a new tobacco or vape product is “appropriate for the protection of public health.” In the European Union, similar objectives are pursued under the Tobacco Products Directive (TPD 2014/40/EU), which governs ingredient disclosure, toxicological evaluation, and emission testing.

While nicotine levels, device design, and emission profiles are critical, flavorings are the most complex component to justify scientifically. They consist of intricate mixtures of aroma molecules, many of which were never designed for inhalation. Each component must be chemically characterized, evaluated for toxicological safety, and justified under regulatory frameworks.

This blog post explains the scientific and regulatory role of flavorings in PMTA submissions—covering analytical testing, toxicology, documentation, EU parallels, and best practices for compliance. It is designed for formulation scientists, quality managers, and regulatory affairs professionals seeking practical and authoritative insights.

The PMTA process was established under the Family Smoking Prevention and Tobacco Control Act (FSPTCA) of 2009, granting the FDA authority over electronic nicotine delivery systems (ENDS). Any vape product or e-liquid introduced after August 8, 2016, must have an approved PMTA before being legally marketed in the U.S.

A PMTA submission includes:

The FDA evaluates whether the new product benefits the overall public health, balancing potential benefits for adult smokers against risks to non-users and youth (FDA, 2024).

In Europe, the Tobacco Products Directive (TPD) does not follow a PMTA-style premarket authorization process but enforces product notification and ingredient safety reporting. Manufacturers must provide a full list of ingredients, toxicological data, and emissions analyses through the EU Common Entry Gate (EU-CEG) before products reach the market.

Both systems—PMTA and TPD—share a fundamental purpose:

To ensure that the marketing and use of vape products do not expose consumers to unnecessary risks and are scientifically substantiated.

Flavorings serve two interconnected purposes:

A typical e-liquid flavor may contain 50 to 200 compounds, including esters, aldehydes, ketones, terpenes, and lactones. Many of these compounds are safe for oral consumption but lack inhalation safety data. The PMTA requires a detailed understanding of how each component behaves before and after aerosolization.

From a regulatory standpoint, flavorings are pivotal because:

In short, the flavoring component of a vape product is both a sensory differentiator and a compliance challenge.

The PMTA’s Chemistry Report begins with a thorough chemical characterization of all flavoring ingredients. Analytical techniques such as:

are used to identify and quantify all volatile and semi-volatile components.

The resulting data provide:

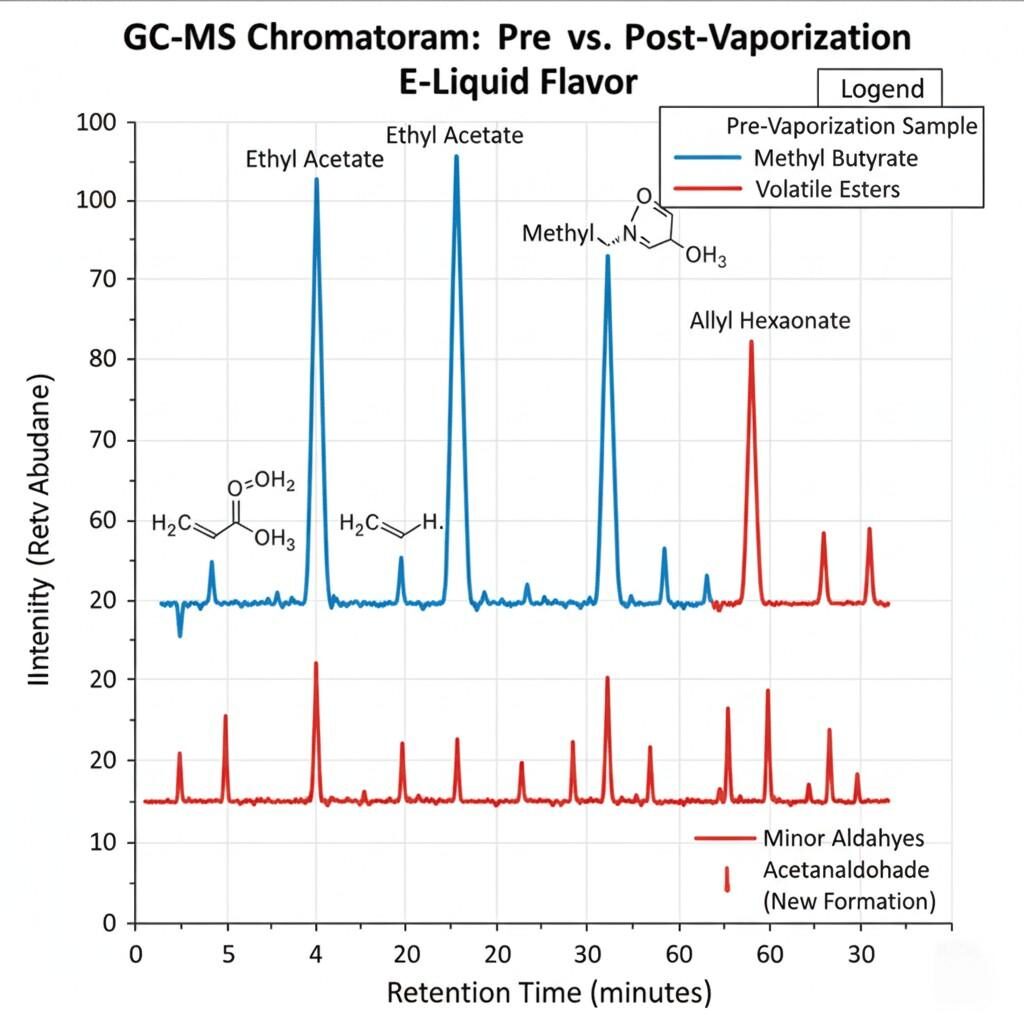

E-Liquid Flavor Vaporization GC-MS

Regulators require proof that each production batch maintains consistent chemical profiles. GC–MS fingerprinting and analytical reproducibility studies are therefore critical. Deviations between batches can lead to PMTA deficiencies or rejections.

For toxicological prioritization, ingredients are typically grouped as:

Documentation from ECHA REACH and PubChem databases provides the necessary regulatory cross-references (ECHA, 2024).

The PMTA’s toxicological review addresses two main questions:

Data sources include:

The goal is to ensure exposure levels remain well below established toxicological thresholds.

Since direct inhalation data are limited, regulators accept computational toxicology tools such as QSAR and read-across to predict potential effects. Molecular structure databases and toxicity reference systems allow scientists to evaluate risk based on chemical similarity to known toxicants.

PMTA toxicology must demonstrate that the inclusion of a flavoring does not increase the formation of harmful or potentially harmful constituents (HPHCs) such as carbonyls, formaldehyde, or acetone during vaporization (FDA Science Forum, 2023).

The strength of a PMTA flavor dossier often depends on the clarity and credibility of toxicological justification.

When heated, some flavor molecules break down, creating new compounds. Esters can hydrolyze to form acids and alcohols, aldehydes can oxidize, and certain diketones (e.g., diacetyl) can re-form at high temperatures.

Regulators require testing of emissions under standard vaping conditions, measuring:

Aerosol studies must demonstrate that the addition of a flavoring system does not significantly increase harmful emissions compared to a flavorless control. Data integrity and reproducibility are key for regulatory acceptance.

To complement emissions testing, stability studies assess how flavor compositions evolve over time under controlled storage. These results form part of the Shelf-Life and Stability Report within PMTA documentation.

The EU TPD Article 20 governs e-liquid formulation and ingredient notification. While less exhaustive than PMTA, it emphasizes:

Member States may impose stricter measures—such as flavor bans or concentration limits—on specific substances. Therefore, maintaining dual compliance systems (PMTA + TPD) ensures smoother international operations for global vape manufacturers.

A PMTA dossier also assesses manufacturing and quality control systems. Regulators want assurance that every flavoring batch is:

A compliant flavor supplier, such as CUIGUAI Flavoring, ensures:

Cleanroom QA/QC Review

Robust documentation not only strengthens PMTA applications but also builds long-term credibility with regulators and brand partners.

Flavor science is both an art and a discipline. While PMTA regulations impose limits, they also encourage scientifically informed creativity—designing complex yet safe flavor systems that deliver consumer satisfaction without regulatory risk.

Manufacturers can focus on:

Modern laboratories employ GC–Olfactometry (GC–O) to correlate molecular peaks with sensory descriptors. This enables developers to design flavors that are not only compliant but also sensorially optimized for mature markets.

At CUIGUAI Flavoring, we provide scientifically validated flavor systems with:

Our technical support ensures that flavor innovation aligns with compliance, not against it.

| Issue | Example | Impact |

| Incomplete ingredient disclosure | Missing CAS numbers or confidential additives | Regulatory deficiency notice |

| Unsupported GRAS assumptions | Assuming food-grade safety implies inhalation safety | Rejection or re-testing |

| Lack of emission studies | No proof of aerosol safety | PMTA non-acceptance |

| Inconsistent analytical results | Batch-to-batch GC–MS variation | Product deemed unstable |

| Missing documentation | Absent COA, SDS, or toxicology sheet | Administrative deficiency |

Avoiding these pitfalls requires early collaboration between flavor suppliers and PMTA applicants, ensuring every data point is ready before submission.

A truly compliant flavoring system integrates science, documentation, and safety evaluation. The framework typically includes:

With these components, flavor manufacturers demonstrate a culture of compliance and scientific responsibility.

The next decade will see major transformations in vape flavor regulation and technology. Key trends include:

Flavoring companies that integrate these innovations early will be positioned as strategic regulatory partners, not just suppliers.

As global regulatory frameworks evolve, flavorings will remain at the heart of every vape product’s compliance journey. Manufacturers must embrace:

Global Vape Regulation & Compliance

Flavorings are not just taste components—they are the scientific identity of every vape product. A successful PMTA submission treats flavor not as an obstacle, but as an opportunity for excellence in chemistry, toxicology, and manufacturing integrity.

At CUIGUAI Flavoring, we combine advanced analytical science, GMP production standards, and complete regulatory documentation to support brands through the complex PMTA and TPD processes. Our team works directly with formulators and compliance officers to design PMTA-ready flavoring systems that meet both scientific rigor and market appeal.

For PMTA documentation support, custom formulation, or free sample requests, contact our expert team:

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.com]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Let’s create compliant, innovative, and safe flavor solutions for the future of vaping.

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy