Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Dec 12, 2025

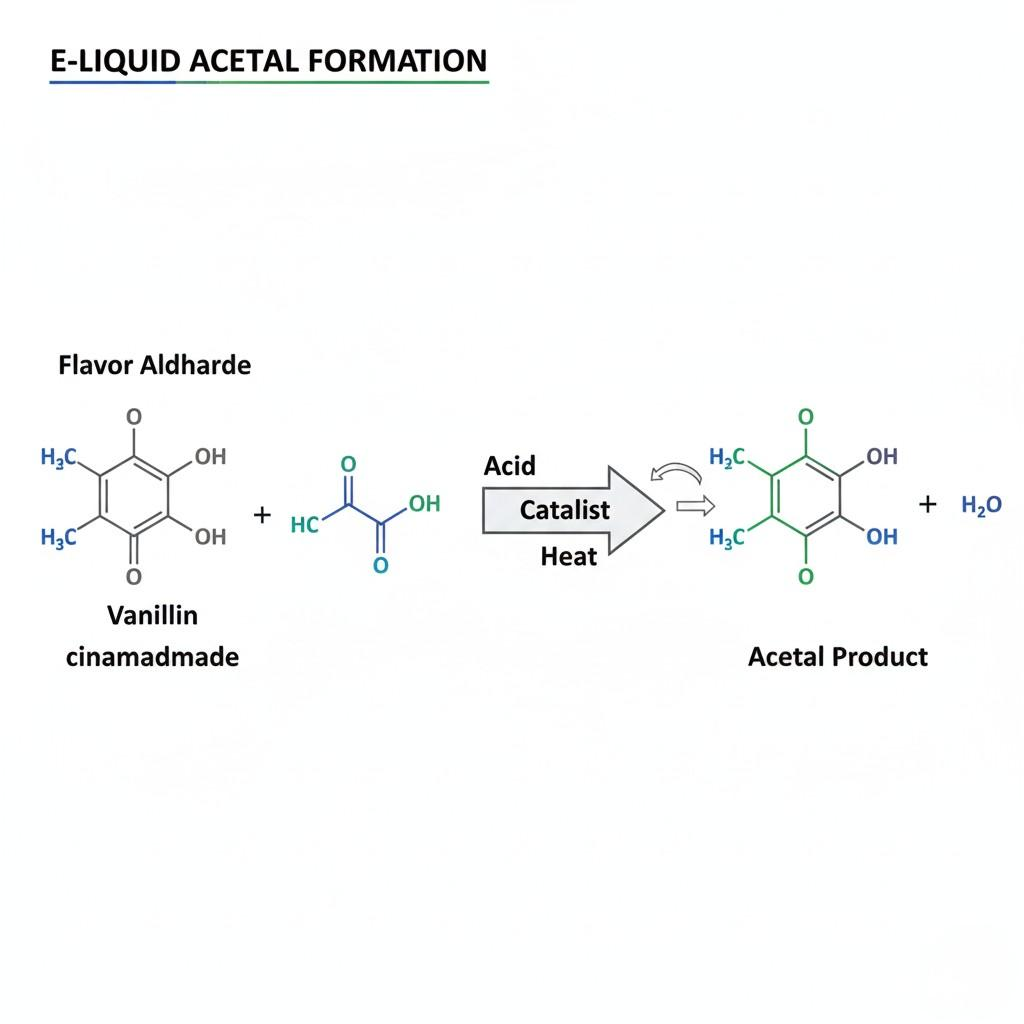

E-Liquid Acetal Formation Diagram

As a manufacturer of flavorings for electronic liquids (e-liquids), you’ve likely encountered this paradox: a flavor concentrate may smell rich, full, and appetizing during mixing — yet once vaped, the result can be disappointing: muted flavor, off-notes, burnt aftertaste, coil gunk, or simply a “flat” profile.

This recurring problem — why some flavorings perform well in mixing but fail in real-world vaping — is not just a matter of subjective taste. It’s rooted in deep chemical, physical, and device-system interactions that distinguish static mixing from dynamic aerosolization. Understanding these mechanisms is essential to produce robust, consistent, and consumer-pleasing e-liquids.

In this article, we dissect the causes behind flavor failures in vaping, backed by scientific evidence, practical formulation insights, and industry-aware best practices. We aim to provide a definitive, technically-grounded guide for flavor houses, R&D teams, and OEM/ODM partners — showing not only what fails, but why, and more importantly, how to avoid it.

At first glance, mixing flavor concentrate into a PG/VG (propylene glycol / vegetable glycerin) base seems straightforward. A strong aroma in the bottle suggests success. But vaping is a high-stress, high-temperature, phase-transition process. The operating conditions and physics are radically different.

Key differences:

Because of these transformations, a flavor that “works on paper” can collapse under real vaping conditions.

Here, we explore the most frequent scientific and technical reasons why flavorings fail when vaped — even if they appeared fine at mixing.

Many flavor compounds — particularly esters, aldehydes, alcohols, and some ketones — are thermally labile. Under the high heat generated by coils, they can decompose into simpler or more reactive species: acids, carbonyls, alcohols, or other fragments.

A notable study modeled the thermal decomposition of ethyl ester flavor additives under vaping temperatures and found that at higher coil temperatures, these esters can break down into carboxylic acids, which themselves could further degrade into toxic products under extreme conditions .

Implications of thermal decomposition:

Even before heating, flavor aldehydes show a tendency to react with carriers such as PG (propylene glycol) or VG (glycerol), especially in the presence of acids (e.g., benzoic acid in nicotine salts). This reaction — acetalization — leads to the formation of flavor-aldehyde PG/VG acetals.

A pivotal study using proton NMR spectroscopy demonstrated that flavor aldehydes like benzaldehyde, vanillin, cinnamaldehyde, and citral rapidly convert to acetals in standard e-liquid solvents. Over 40% of the original aldehyde content was converted into acetals even at room temperature, and 50–80% of those acetals were carried over into vapor during vaping .

Why this matters:

Beyond immediate mixing issues, many flavor compounds degrade over time. Exposure to oxygen, light, or residual reactive impurities can trigger oxidation, hydrolysis, or polymerization.

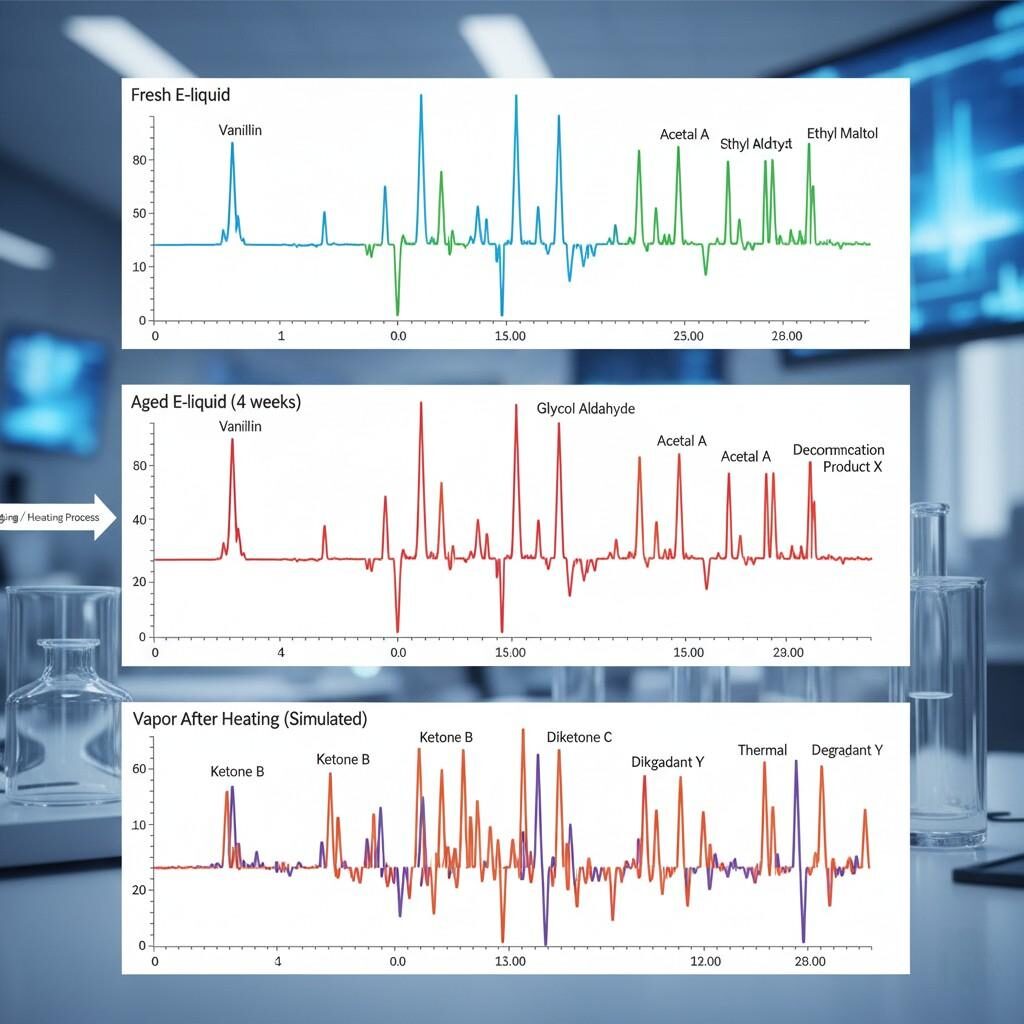

A long-term aging study of 20 common flavoring chemicals in e-liquids found significant degradation over 24 months — particularly when stored at room temperature under ambient light. The authors identified likely degradation products via GC–MS, including oxidation and condensation byproducts. They concluded that storing e-liquids in cold, dark environments significantly slows degradation, but even then, many flavors lose potency or change profile over time .

Impacts on vaping quality:

Flavor concentrates often mix well in PG/VG under lab conditions, but when the e-liquid is filled into devices — especially high-VG or “max-VG” blends — the physical properties change.

High viscosity slows diffusion, liquid flows less readily through wick fibers, and aromatic compounds may form micro-droplets or separate phases. This causes:

Associations that track flavor stability note that many “cheap” or non-optimized flavorings fail under exactly these conditions: low solubility, impurity content, reactive chemicals — resulting in inconsistent performance and consumer rejection Source+1(CUIGAUI).

Flavors must survive device-level stresses:

Even a well-formulated flavor can fail if the hardware conditions are mismatched. This hardware–flavor mismatch is a major root cause of “works in bottle but fails in vape.”

In a laboratory study comparing flavored vs unflavored e-liquids, researchers observed consistent increases — sometimes 150–200% — in acetaldehyde (a carbonyl) emissions when flavor additives were present, even under nominal vaping conditions. Acrolein and formaldehyde changed variably depending on the flavor formulation .

This demonstrates that flavor compounds do not simply carry over into aerosol unchanged; they may degrade or transform, generating entirely different chemicals that can affect aroma, throat hit, and safety.

As referenced above, the study from the team at Duke University and Yale University showed that within hours or days of mixing, significant portions of flavor aldehydes convert to PG/VG acetals — molecules distinct from the original flavorants. Many of these acetals transfer to vapor and remain stable in physiological conditions, even activating airway-irritant receptors .

Therefore, even a static, well-blended e-liquid can become a chemically different mixture in storage — before even being vaped.

The 24-month naturalistic aging study (reference earlier) tested 20 popular flavor chemicals, including benzaldehyde (cherry), vanillin (vanilla), and menthol (cooling). Under typical storage (ambient temperature + light), many of these degraded significantly, with evidence of oxidation, hydrolysis, and condensation byproducts identified by GC–MS.

Lower-temperature, dark storage reduced—but did not eliminate—degradation. This shows that flavor fade over time is real and that storage conditions matter greatly for long-term flavor stability and vaping performance .

Macro Shot of E-Cigarette Coil Gunk

Here are the typical “failure modes” seen when flavoring works in mixing but fails in actual vaping:

| Failure Mode | Observed Symptoms | Root Causes |

| Muted / weak flavor | Vapors taste thin, weak, “watery” | Loss of volatiles due to solubility, acetalization, or evaporation; insufficient volatility for aerosolization |

| Off-flavor / harsh taste | Sourness, bitterness, chemical taste, throat irritation | Thermal decomposition (acids, carbonyls), oxidation byproducts, acetals activating irritant receptors |

| Coil gunk / rapid coil fouling | Coil darkening, reduced vapor, burnt taste after small volume | Heavy oils, sugars, high-boiling flavor bases, decomposition products depositing on coil/wick |

| Flavor inconsistency over time / batch drift | First bottles strong; later bottles (or after storage) weak or different | Instability of flavor chemicals, degradation during storage, carrier interactions |

| Safety/regulatory risks | Unexpected irritants, unknown chemical byproducts | Aldehyde-PG acetals, carbonyl emissions, decomposition products |

Understanding these failure modes is vital — they guide which flavor systems to avoid and which to design carefully.

As a flavor manufacturer aiming for high reliability and repeatability, you can adopt the following structured workflow to minimize vaping failures.

Given the challenges, a well-engineered flavor system for vaping should have these properties:

Practically, this often means:

By doing so, flavor houses can produce “vape-ready” concentrates that perform reliably across mixing, storage, and real-world vaping.

What to do differently: use more volatile esters (e.g., ethyl butyrate, methyl esters), reduce heavy lactones, add mouthfeel enhancers like light acetates, test in intended coil/wick device.

Better approach: Replace benzaldehyde with a stable ester-based cherry/almond mimic; avoid heavy oil or limit concentration; monitor for acetal formation; test aerosol by GC–MS.

Better approach: use light-stable citrus esters, include antioxidants, specify cold-dark storage, reduce headspace, consider nitrogen purge before sealing.

E-Liquid Degradation via GC–MS

In the flavor industry, “cheap” doesn’t just mean inexpensive — it often means low purity, impure raw materials, lack of analytical traceability, non-optimized solvent compatibility, and no stability testing. Such flavorings may pass a sniff test in a mixing lab, but they almost always fail under real vaping conditions.

Common issues with low-quality flavorings:

Residual solvents or peroxides that accelerate degradation.

Batch-to-batch chemical variation — resulting in inconsistent flavor.

High-boiling, heavy oil components that gum coils.

Lack of analytical data (GC–MS fingerprint, NMR stability, etc.), making quality control impossible.

Ultimately, the money “saved” at mixing often results in consumer complaints, return rates, poor coil life, and brand damage — far more costly than using higher-quality, well-characterized flavor concentrates. Source+2(CUIGUAI)

As a responsible flavor manufacturer, you must consider not just flavor performance, but chemical stability, degradation byproducts, and inhalation safety. Several peer-reviewed studies have demonstrated that:

Given this, it is not sufficient to rely on “food-grade” approval or GRAS status — those typically apply to ingestion, not inhalation. For e-liquids, inhalation safety and thermal stability under aerosolization must be taken into account.

As such, flavor houses should adopt rigorous analytical testing frameworks, maintain full documentation, and perform aerosol-phase GC–MS or TD-GC–MS to ensure their formulations remain safe and effective in real use.

For flavor manufacturers seeking high reliability in vaping applications, the following checklist can serve as a baseline standard:

By adhering to these practices, flavor houses can significantly reduce the risk of flavor failure, maintain consistency across batches, and preserve brand reputation while ensuring safer, more predictable vaping products.

E-Liquid Flavor Formulation in Lab

In the world of vaping, mixing success does not guarantee vaping success. The dynamic environment of aerosolization — high heat, chemical reactivity, phase transitions — transforms e-liquids into complex chemical systems. Many flavorings that perform admirably in a mixing lab collapse under those conditions, resulting in weak aroma, off-notes, coil fouling, or safety issues.

However, armed with a deep understanding of the underlying mechanisms — thermal decomposition, acetalization, solvent interactions, volatility limitations, device constraints — flavor houses can design robust, vape-ready flavor concentrates that deliver consistent, high-quality performance.

Implementing rigorous analytical testing, proper ingredient selection, stability protocols, and device-specific validation should not be optional — they should be standard best practices.

By doing so, you safeguard not only your flavor’s performance but also brand integrity, consumer trust, and compliance.

If you’re searching for professional-grade flavor concentrates, device-specific R&D, or full stability & aerosol testing services, we’re here to help. We offer:

Contact us today:

| Contact Channel | Details |

| 🌐 Website: | www.cuiguai.com |

| 📧 Email: | info@cuiguai.com |

| ☎ Phone: | +86 0769 8838 0789 |

| 📱 WhatsApp: | +86 189 2926 7983 |

Let’s work together to ensure your flavors perform flawlessly — from mixing bench to final puff.

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy