Printed cigarette oil atomizers of the future

In a world increasingly shaped by personalization and on-demand experiences, the vaping industry is on the cusp of a revolutionary leap. Forget pre-set flavors and limited options; we’re talking about a future where your vape cartridge is as unique as your palate, crafted precisely to your desires, and delivered with unprecedented precision. This isn’t science fiction—it’s the reality emerging from the convergence of 3D printing technology and advanced flavor science. Welcome to the era of 3D-Printed Flavor Cartridges, where custom aroma profiles are not just a possibility but a readily achievable reality.

The core promise of this innovation lies in its ability to empower users. Imagine designing your perfect vape experience, not just by choosing from a menu, but by literally building the flavor from the ground up. This article will delve into the intricate technicalities, the transformative benefits, and the exciting future of this groundbreaking technology.

At its heart, a 3D-printed flavor cartridge is a highly engineered vessel designed for the precise containment and vaporization of e-liquids. But unlike conventional cartridges, these are not mass-produced plastic molds. Instead, they are intricate, layer-by-layer constructions, often incorporating microfluidic channels and customizable internal structures.

The magic begins with additive manufacturing, commonly known as 3D printing. While various 3D printing technologies exist, several are particularly well-suited for creating the complex geometries required for flavor cartridges:

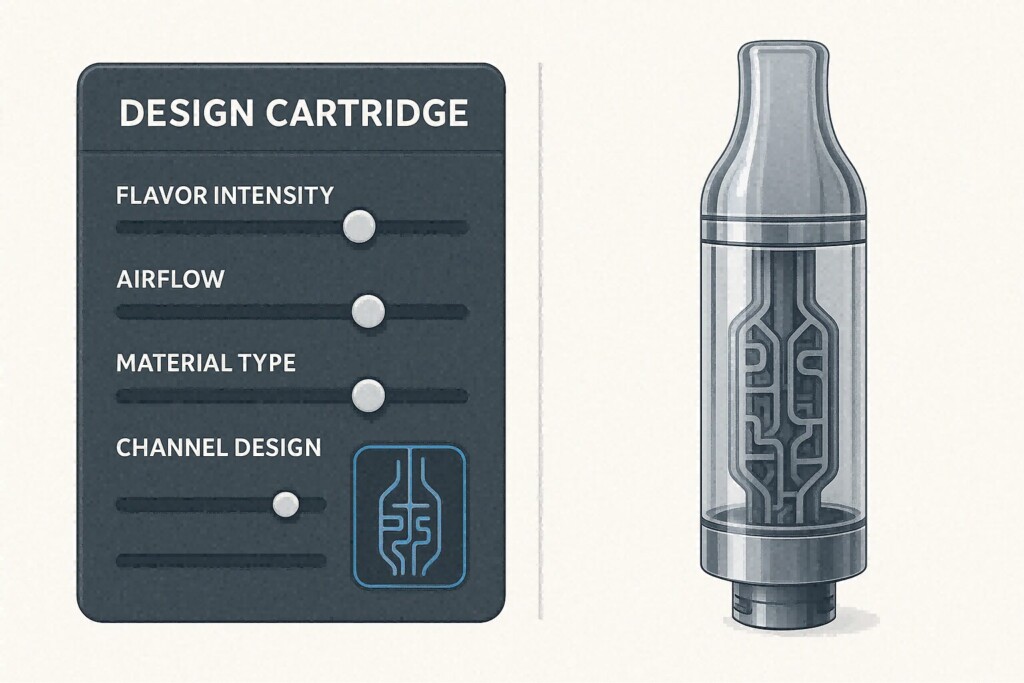

The true innovation isn’t just printing a container; it’s designing the container to actively enhance and customize the aroma experience. This involves several critical design considerations:

The ability to create a truly custom aroma profile is where 3D-printed cartridges truly shine. This isn’t merely about mixing pre-made e-liquids; it’s about engineering the delivery system to complement and enhance the e-liquid itself.

Digital e-liquid design and 3D printing display

While 3D printing handles the cartridge, the e-liquid itself remains crucial. High-quality e-liquids, especially those designed with a wide range of nuanced flavor notes, will truly shine with a custom-engineered cartridge. For those seeking unparalleled flavor fidelity and depth, we highly recommend exploring CUIGUAI Flavoring e-liquids. Their meticulous blending and use of premium ingredients ensure a superior base for any custom aroma profile you envision. When you have the precision of a 3D-printed cartridge, pairing it with an e-liquid like CUIGUAI Flavoring allows you to unlock the full spectrum of its intended taste.

The advent of 3D printed vape cartridge technology has far-reaching implications, extending beyond individual consumer benefits to reshape the entire vaping ecosystem.

For e-liquid manufacturers and device developers, 3D printing offers an unprecedented advantage in rapid prototyping. New cartridge designs can be printed and tested within hours, drastically shortening development cycles and allowing for faster iteration on improvements. This means more innovative products reaching the market sooner.

Small-batch production becomes economically viable. This opens doors for specialized e-liquid companies to offer bespoke cartridge designs optimized for their unique flavor profiles, creating a highly customized and premium experience for their customers. Imagine a master blender creating an e-liquid so complex that it requires a specific cartridge internal geometry to truly express all its notes.

Localized manufacturing becomes a real possibility. Instead of relying on distant factories and complex global supply chains, cartridges could be printed on-demand closer to the point of sale, reducing lead times and increasing supply chain resilience. This could also reduce waste by minimizing overproduction.

While 3D printing itself uses materials, the ability to print on-demand and potentially recycle used cartridge materials locally could significantly reduce waste compared to traditional mass manufacturing. Furthermore, the precision of 3D printing can minimize material waste during the manufacturing process itself.

While the future of 3D-printed flavor cartridges is undeniably bright, several challenges need to be addressed to realize its full potential.

Ensuring the safety and inertness of 3D-printable materials for prolonged contact with e-liquids and inhalation is paramount. Rigorous testing and regulatory frameworks will be essential to build consumer trust. This includes evaluating potential leachables, thermal stability, and overall biocompatibility of the cured resins.

As the technology evolves, establishing industry standards for cartridge design, material properties, and perhaps even digital design files will be crucial for widespread adoption and consumer convenience. This ensures that a custom-printed cartridge from one source can be used with various vaping devices.

While prototyping is cost-effective, scaling 3D printing for mass production of custom cartridges will require advancements in print speed, material costs, and automation. As 3D printing technology matures and becomes more accessible, these costs are expected to decrease.

For consumers to fully embrace custom aroma profiles, intuitive and user-friendly design software will be vital. Imagine a simple app where users can adjust sliders for “sweetness,” “fruitiness,” “menthol intensity,” and see a real-time visualization of how the cartridge’s internal structure adapts.

Five 3D printed e-cigarette ink tubes

The emergence of 3D-printed flavor cartridges represents a paradigm shift in the vaping industry. It moves beyond mass production to embrace the power of personalization, offering consumers an unprecedented level of control over their vaping experience. From fine-tuning flavor intensity to exploring complex custom aroma profiles, the possibilities are limited only by imagination.

As the technology continues to mature, we can anticipate a future where your vape cartridge is not just a container but an integral part of your personalized flavor journey. This convergence of advanced manufacturing and consumer desire for unique experiences is set to redefine how we perceive and enjoy e-liquids. The future of vaping is here, and it’s being printed, one exquisite flavor profile at a time.

Mobile phone and electronic cigarette equipment display

Keywords: 3D printed vape cartridge, custom aroma,E-liquid flavor concentrate

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jul 11, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy