China has emerged as a powerhouse in the global vape industry, particularly in the field of vape flavor manufacturing. Driven by rapid innovation, robust supply chains, and cost-efficient production, Chinese manufacturers have become critical partners for e-liquid brands around the world. As vaping products become more sophisticated, so do the requirements for consistent, safe, and appealing flavor delivery.

This article provides a deep dive into the vape flavor manufacturing ecosystem in China, highlighting the country’s quality control processes, regulatory compliance measures, technical R&D capabilities, and how leading suppliers such as CUIGUAI Flavoring deliver tailor-made, global-standard flavor solutions. With insights targeted at B2B buyers, product developers, and sourcing managers, this article also includes key evaluation criteria and trend predictions that will shape the future of the industry.

Global Vape Flavor Manufacturing Landscape

The global e-liquid market is projected to surpass USD 25 billion by 2030, driven by growing acceptance of vape products as alternatives to traditional cigarettes. Key consumer drivers include the availability of diverse flavor profiles, nicotine flexibility, and innovations in device technology. Fruity flavors lead the global preference, followed by menthol, tobacco, dessert, and beverage-inspired blends.

China is not just the world’s largest producer of vape devices—it is also a major hub for vape flavor concentrate manufacturing. Industrial clusters across Guangdong and Zhejiang have optimized raw material sourcing, flavor R&D, and mass production under one roof. China’s ability to integrate supply chain management with technical innovation gives manufacturers a decisive edge in speed, cost, and scalability.

| Benefit | Description |

| Cost Efficiency | Bulk raw sourcing, automation, low labor costs |

| Customization | Modular flavors suited to international palates |

| Fast Time to Market | 2–3 week R&D cycles, flexible MOQ |

| Compliance Support | Documentation for TPD/FDA audits |

| IP Protection | NDA enforcement and exclusive formulation services |

Chinese vape flavor manufacturers deploy advanced flavor science, utilizing both sensory analysis and instrumental validation to design high-performance e-liquid concentrates. Tools include:

Inside a Chinese Vape Flavor Lab

Reputable Chinese manufacturers work exclusively with certified suppliers offering food-grade, pharmaceutical-grade, and/or FEMA-approved ingredients. Common materials include:

Manufacturers conduct regular audits and maintain full traceability of incoming materials, including lot number records, supplier COAs, and impurity profiles.

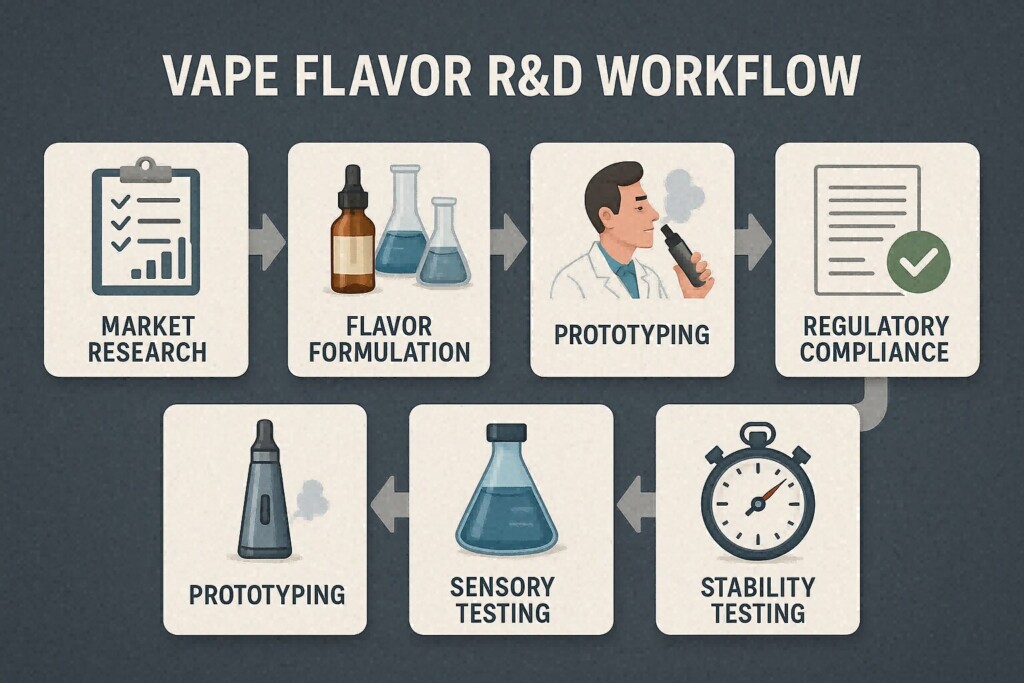

The process of creating a new vape flavor is rigorous and iterative. A typical R&D cycle includes:

Vape Flavor R&D Workflow

Top factories in China can produce over 200 tons of flavor concentrate annually while maintaining batch consistency within ±0.5% variance.

Manufacturers provide comprehensive documentation with every shipment:

Chinese manufacturers utilize ERP systems to track batch progression in real time. High-performing factories conduct:

China’s domestic e-liquid production is overseen by the State Tobacco Monopoly Administration (STMA), which issues production permits, tracks licensing, and enforces quality checks. Manufacturers must comply with GB/T 41700 national standards.

| Region | Regulation | Requirement |

| EU | TPD | Ingredient notification, emissions testing, labeling |

| USA | FDA PMTA | Toxicology reports, usage analysis, flavor chemical listing |

| UK | MHRA | Product submission, marketing compliance |

| MEA | SASO/GSO | Halal flavor requirements, bilingual labeling |

Top Chinese suppliers proactively ensure:

CUIGUAI Flavoring, founded in 2015, has rapidly built a reputation as a premier vape flavor concentrate manufacturer in southern China. Their 2,000-square-meter production facility integrates cleanroom blending, gas chromatography labs, and accelerated aging test chambers.

“CUIGUAI’s Ice Mango ranks #1 in customer retention among Asian ODM clients.”

| Evaluation Criteria | What to Look For |

| R&D Capability | GC-MS lab, modular libraries, rapid prototyping |

| Quality Documentation | COA, MSDS, ISO certs, allergen reports |

| Communication | English staff, NDA support, fast sampling |

| Regulatory Familiarity | TPD, FDA, STMA, IFRA knowledge |

| IP Protection | Contractual exclusivity, non-disclosure |

| Logistics Flexibility | DDP, CIF, express sampling options |

With rising consumer awareness, demand is growing for natural flavors, including:

China’s vape flavor industry stands at the intersection of efficiency, innovation, and compliance. For B2B brands seeking a reliable, scalable, and regulatory-aware partner, Chinese manufacturers offer compelling advantages.

CUIGUAI Flavoring exemplifies these strengths—delivering custom, lab-tested vape concentrates with global appeal. Whether you’re launching a new brand or upgrading your current flavor line, partnering with a top-tier Chinese flavor manufacturer is a strategic step forward.

From Factory to Formula

Ready to develop your next breakthrough flavor? Reach out to CUIGUAI Flavoring’s R&D team for consultation, sampling, and project launch today. You’ll receive expert support, transparent documentation, and market-ready results backed by science.

Keyboard:China vape flavor manufacturer,OEM e-liquid flavor factory,Chinese vape flavor supplier,vape flavor concentrate China,vape flavor production factory,best China vape flavor manufacturers for e-liquid brands,TPD compliant e-liquid flavor supplier in China,high-purity vape flavor concentrates made in China,custom e-liquid flavor development for global markets,China PG/VG based e-liquid flavor production,wholesale vape flavor concentrate from China,China e-liquid flavor factory with GMP certification,ISO certified vape flavor producer in Shenzhen,private label vape flavor OEM China,Chinese e-liquid flavor R&D and lab testing

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 23, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy