Advanced Flavor Powder Production

In today’s competitive food, beverage, and specialized industries, especially fast-evolving sectors like e-liquids, flavor preservation and delivery are paramount. Consumers expect authentic, intense, and long-lasting taste experiences. Achieving this often relies on converting liquid flavor concentrates into stable, high-quality powders. Among the most innovative methods are electrostatic spray drying (ESD) and freeze drying. While both aim to encapsulate and protect volatile flavor compounds, they operate on different principles, offering distinct advantages for various applications.

This guide will dive into the technical nuances of electrostatic spray drying and freeze drying, comparing their mechanisms, operational aspects, and specific benefits for flavor powder production. We’ll explore how each technology impacts flavor retention, shelf life, solubility, and overall product quality—insights crucial for manufacturers aiming to optimize processes and gain a competitive edge. Understanding these advanced techniques is about making a strategic decision that directly influences your product’s sensory profile, stability, and market appeal. For instance, in the rapidly expanding e-liquid market, consistent and potent vape flavor delivery is key, making the choice of drying technology a critical factor in user satisfaction and product longevity.

Converting liquid flavors into powder form is vital for several reasons. Liquid flavorings, particularly natural ones, are highly susceptible to degradation from oxidation, volatilization, hydrolysis, light, heat, and microbial growth. By encapsulating flavors within a protective matrix and drying them, these vulnerabilities are significantly reduced.

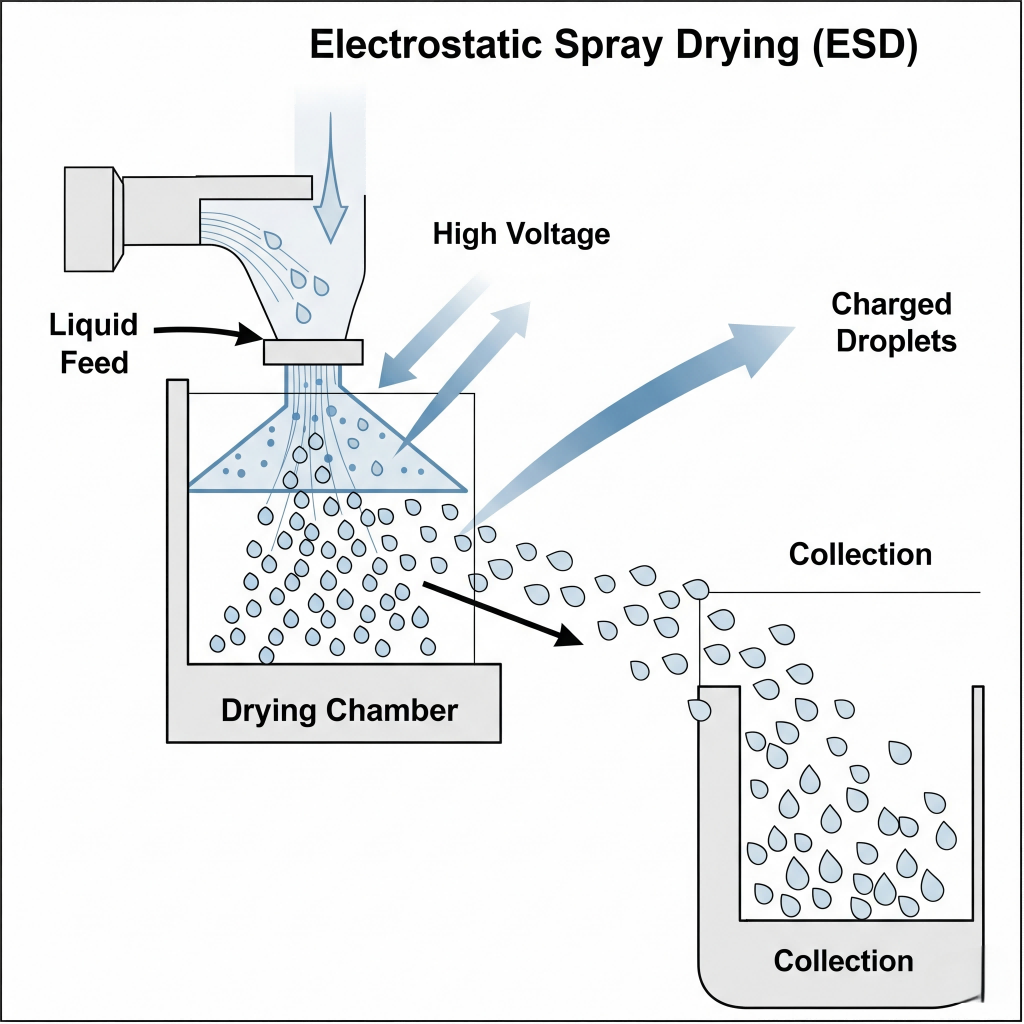

Electrostatic spray drying (ESD) is an advanced form of conventional spray drying that uses an electrostatic field to improve atomization and particle formation. While traditional methods rely on mechanical forces, ESD introduces an electrical charge, offering superior control over droplet size and distribution. This precision is particularly beneficial for encapsulating sensitive, volatile flavor compounds.

Freeze drying, or lyophilization, is a low-temperature dehydration process. It involves freezing a product and then reducing the surrounding pressure to allow ice to sublimate directly from solid to gas. This avoids high temperatures, making it ideal for extremely heat-sensitive flavors.

Product Bulkiness:Porous structure leads to lower bulk density, impacting storage and transport.

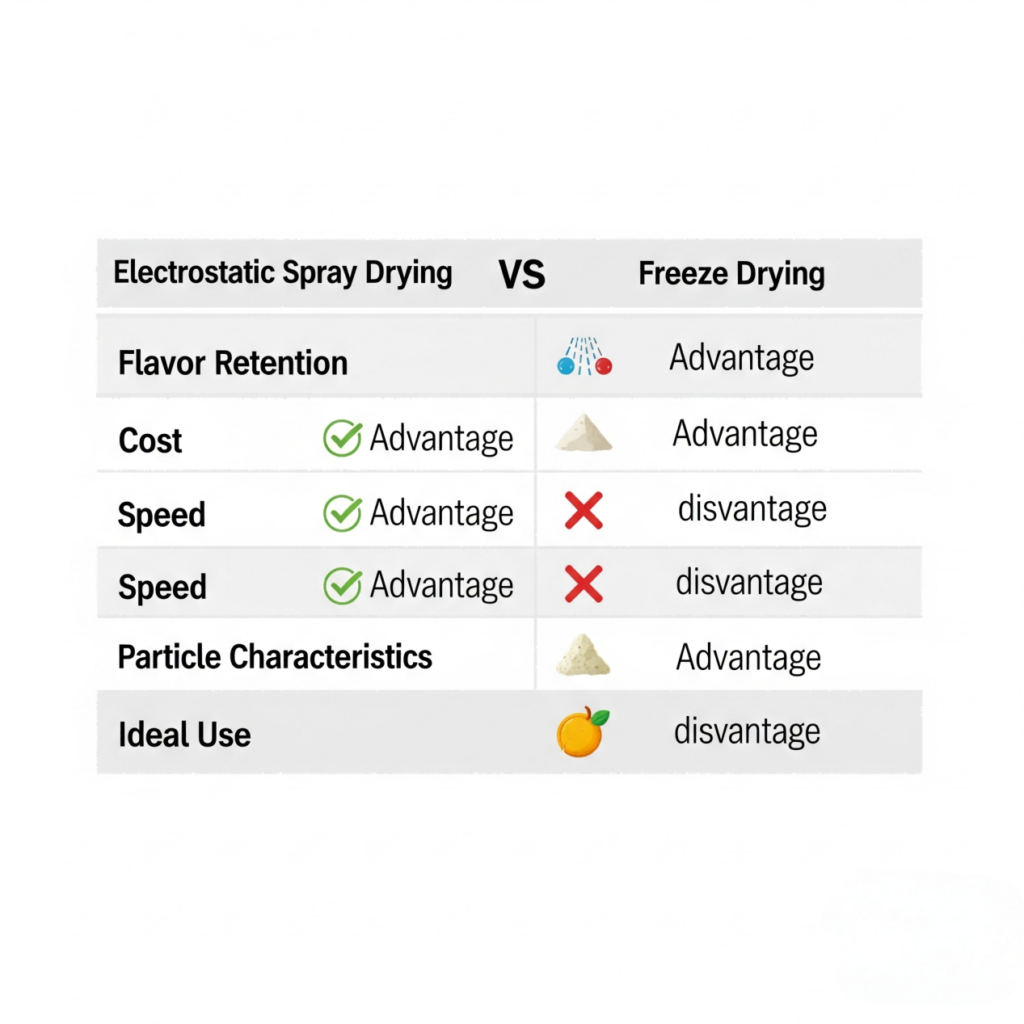

Choosing between ESD and freeze drying is a critical decision based on specific flavor needs, product characteristics, cost, and production scale.

| Feature | Electrostatic Spray Drying (ESD) | Freeze Drying (Lyophilization) |

| Flavor Retention | Excellent (superior to conventional spray drying), good for many volatile compounds. | Exceptional (Gold Standard), preserves most delicate, heat-sensitive flavors. |

| Cost (Capital & Ops) | Moderate to High (lower than freeze drying for similar capacity). | Very High (significant investment & operating costs). |

| Processing Speed | Fast, continuous process (seconds to minutes). | Very Slow, batch process (hours to days). |

| Throughput | High, suitable for mass production. | Low, limits high-volume production. |

| Particle Form | Fine, spherical, uniform. Good flowability. | Porous, often irregular, sometimes fragile. Excellent rehydration. |

| Product Suitability | Wide range of flavors, efficient for high volume, e.g., stable vape flavor powders. | High-value, extremely heat-sensitive, natural extracts, premium products. |

| Moisture Content | Typically 3-5% | Extremely low, 1-3% |

Your decision should be guided by your specific product needs and market demands.

In the dynamic e-liquid industry, the demand for stable, high-quality, and impactful vape flavors is ever-increasing. Manufacturers face unique challenges: ensuring flavor consistency, preventing degradation, and delivering a potent, true-to-profile taste.

This is where specialized flavor concentrates, designed for advanced drying techniques, become invaluable. Consider CUIGUAI Flavoring for electronic liquids. CUIGUAI Flavoring is meticulously developed with the stability and performance required for sophisticated drying processes, whether it’s the efficient encapsulation of electrostatic spray drying or the gentle preservation of freeze drying. By optimizing their flavor compounds for these advanced techniques, CUIGUAI ensures the vibrant, complex notes of their e-liquid flavors are locked in, protected, and ready for precise delivery in powdered form. This not only enhances the stability of the final e-liquid product but also enables innovative product development, such as powdered e-liquid bases or highly concentrated solid flavor pearls.

The strategic choice of a high-quality, pre-optimized flavor concentrate like CUIGUAI Flavoring, combined with the right drying technology, empowers e-liquid manufacturers to deliver an unparalleled and consistent vape flavor experience, setting a new benchmark for quality and innovation.

Electrostatic Spray Drying (ESD)

Innovation in flavor powder production continues rapidly. Future advancements include:

These advancements promise even more sophisticated and cost-effective ways to deliver stable, high-quality flavors, opening new possibilities across various industries.

Electrostatic Spray VS Freeze Drying

The decision between electrostatic spray drying and freeze drying for flavor powder production is a strategic business choice. Both technologies significantly advance flavor preservation, offering distinct advantages for different applications.

Electrostatic spray drying combines efficiency, cost-effectiveness, and excellent flavor retention for broad applications, especially where high throughput and uniform particle size are critical. Its ability to create highly stable encapsulated flavors makes it increasingly attractive for industries like e-liquids, where precise vape flavor delivery and longevity are paramount.

Freeze drying remains the unparalleled champion for preserving the most delicate, heat-sensitive, and natural flavor profiles. While it has higher costs and longer processing times, the superior product quality, unmatched flavor fidelity, and extended shelf life justify its use for premium and specialized applications.

By carefully evaluating these factors and considering innovative flavor solutions like CUIGUAI Flavoring, companies can unlock new possibilities in flavor delivery, delighting consumers with superior taste experiences and securing their position in a competitive global market. The future of flavor is powdered, and the right drying technology is your key to unlocking its full potential.

A: Powdering flavors enhances stability against degradation, extends shelf life, allows for precise dosing, and improves ease of handling, storage, and transport.

A: ESD uses an electric field to create finer, more uniform droplets, leading to higher encapsulation efficiency, superior flavor retention due to reduced heat exposure, and better powder flowability compared to conventional spray drying.

A: Freeze drying is ideal because it’s a low-temperature process. By sublimating ice directly to vapor under vacuum, it avoids the high temperatures that would degrade volatile and delicate flavor components.

A: For high-volume production, electrostatic spray drying is generally more cost-effective due to its continuous operation, shorter processing times, and lower operational costs per unit compared to batch freeze drying.

A: Yes, both electrostatic spray drying and freeze drying are highly beneficial for e-liquid or vape flavor production. They encapsulate and stabilize flavor compounds, preventing degradation and ensuring consistent, potent flavor delivery in vape products. ESD, with its efficiency, is particularly well-suited for stable, high-quality powdered flavor components for the e-liquid industry.

An innovative, professional, and precise flavor science fragrance laboratory

Keywords: electrostatic spray drying flavor, freeze drying vape,

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jul 08, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy