Keywords: disposable vape flavor design, heat loss vape, fast-burn flavoring

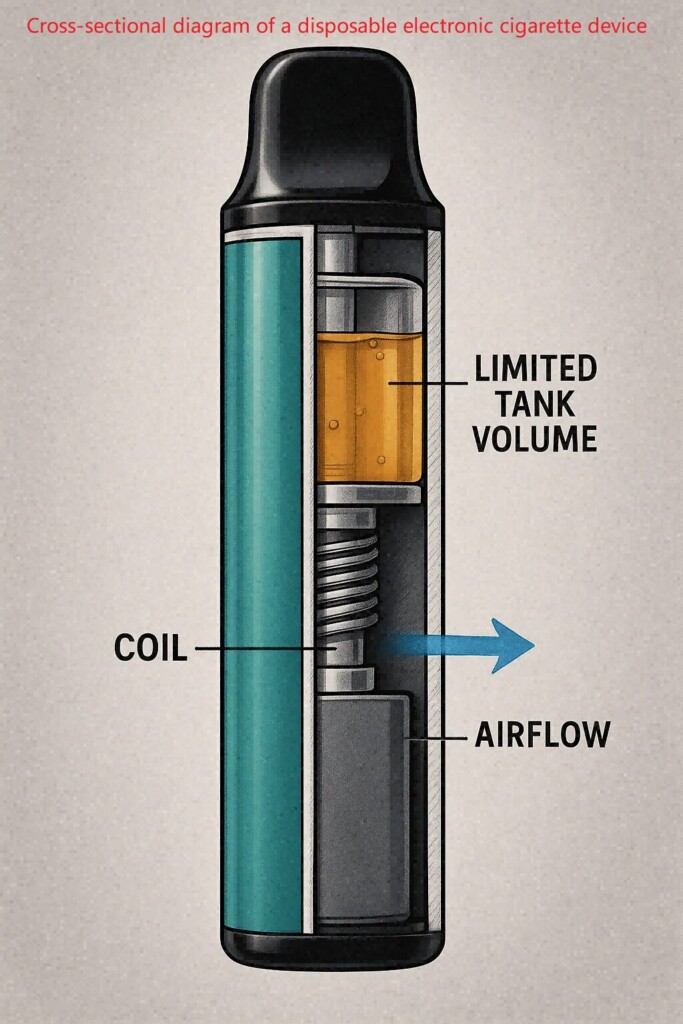

Cross-sectional diagram of a disposable electric cigarette device

Disposable vapes have exploded in popularity due to their convenience, affordability, and increasingly rich flavor offerings. Yet behind the scenes, flavor chemists and vape developers face a unique set of formulation and performance constraints.

Unlike refillable vape systems, disposables operate on tight margins—tiny tanks, minimal power draw, fast-paced consumption—and leave no room for formulation error. Delivering a bold, satisfying flavor from the first puff to the last without overwhelming the coil or gumming up the wick is a high-wire act of precision engineering.

In this article, we’ll explore:

Whether you’re an e-liquid brand formulating for disposables or a device engineer exploring flavor integration, this is your comprehensive guide to making every puff count.

Typical disposables carry just 1.5–6 mL of liquid. This means flavor systems must:

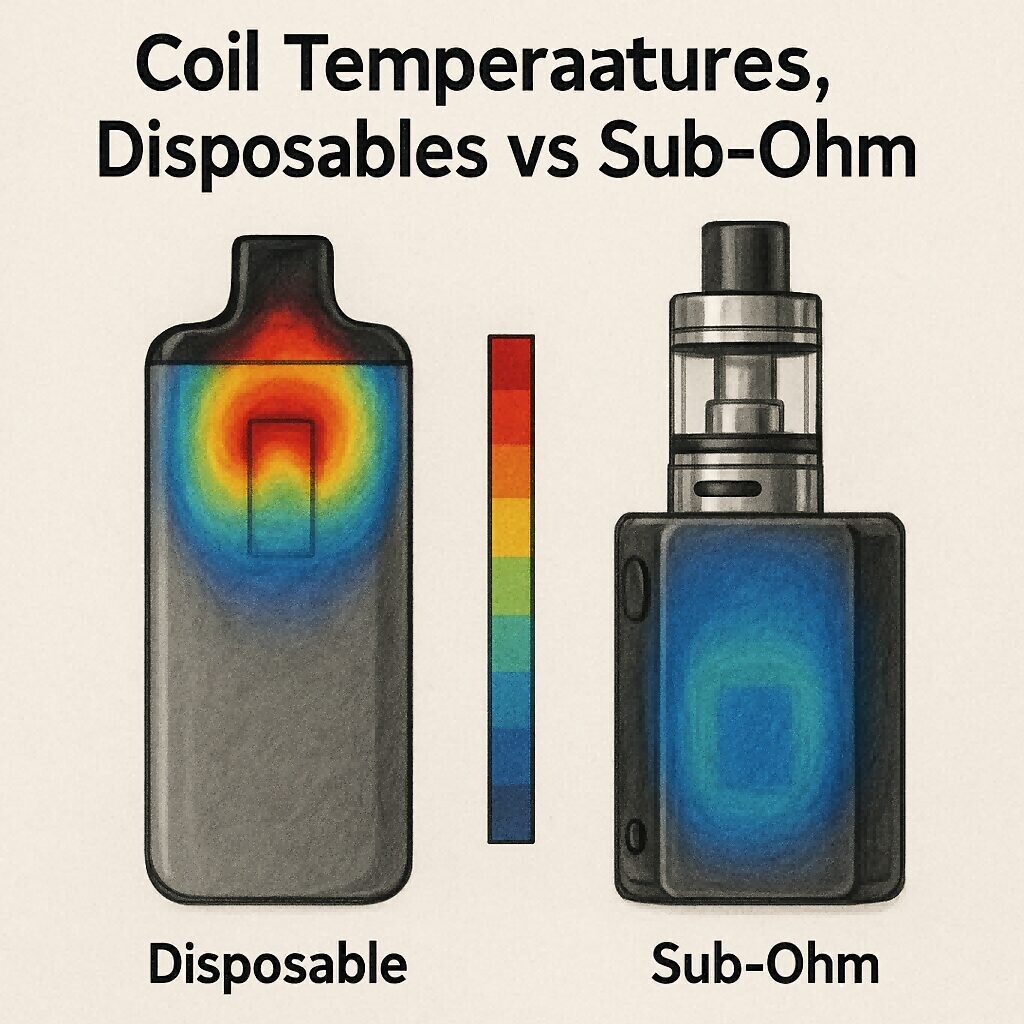

Disposable devices operate at lower wattages (usually <12W). This limits:

This directly affects the “flavor lift”, or the rate at which aromatic volatiles evaporate into inhalable vapor. Flavoring systems must be optimized to activate quickly under mild heat, without requiring steep temperature ramps like sub-ohm mods.

There’s no adjusting airflow or swapping coils. Once a disposable is manufactured, its hardware is locked in. This places high pressure on the flavor design team to ensure:

Coil Temperaatures Disposables vs Sub-Ohm

“Fast-burn flavoring” refers to formulations that release full aroma intensity within the first 0.2 to 0.5 seconds of inhalation—the typical draw length of a puff on a disposable vape.

Ingredients with:

…are prioritized to maximize volatility. However, too many highly volatile top notes without proper support leads to flavor “crash”—an overly strong first puff followed by blandness.

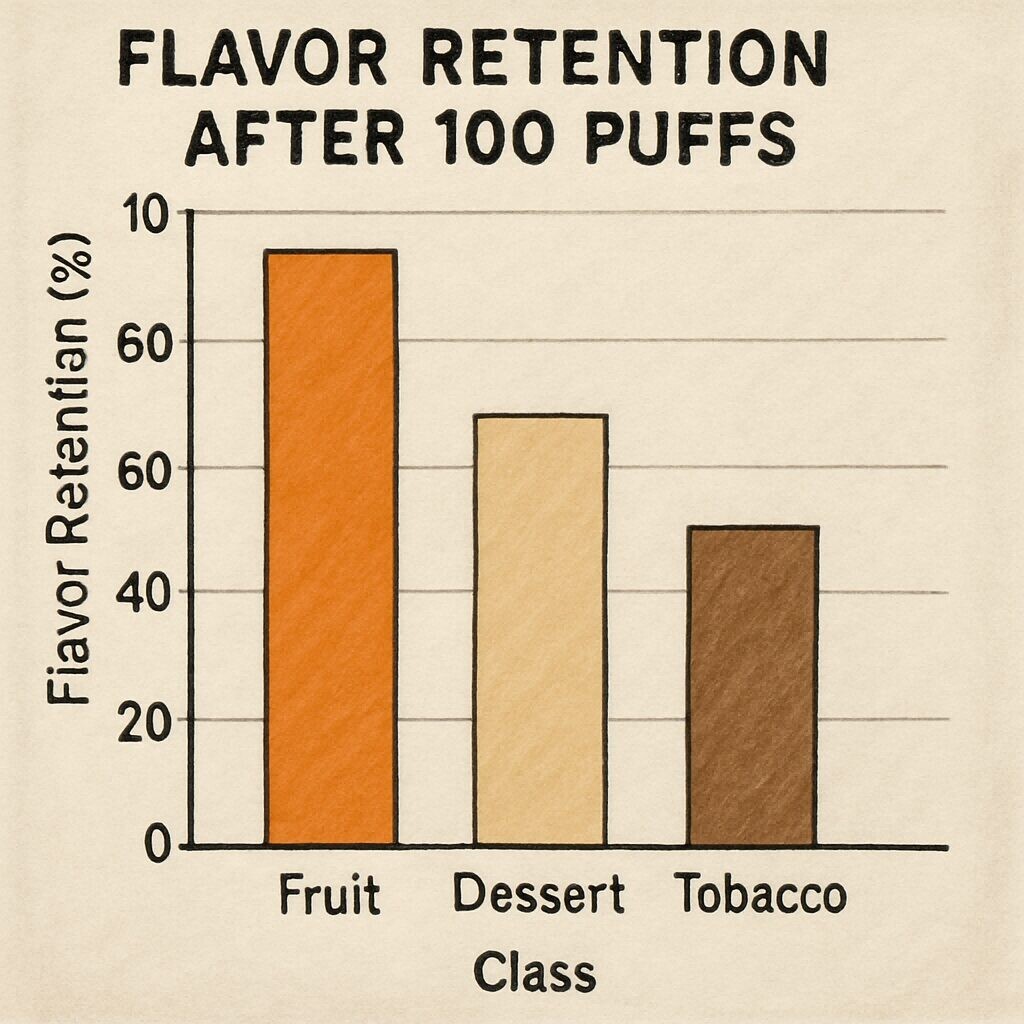

In disposables, much of the generated vapor condenses within the tight chimney structure due to:

Formulators must consider the “heat loss effect”, where aromatic intensity diminishes as vapor cools rapidly before reaching the user’s palate.

Flavor Retention After 100 Puffs

| Constraint | Impact | Flavor Design Strategy |

| Limited tank volume | Less margin for experimentation | High-concentration flavor base |

| Low-watt heating | Weak vaporization of heavy molecules | Use of volatile esters and balanced solvents |

| Short puff time | Demands fast aroma release | Pre-layered top notes |

| Fixed airflow | Cannot “dial in” flavor delivery | Use neutral base to carry volatiles effectively |

| Non-refillable | Once-off impression only | Zero tolerance for bitterness or chemical off-notes |

Using micro-layering to design depth in flavor with minimal ingredients. Top notes (fruity), body (creamy/smooth), and end notes (cooling or spice) must all work within 3 seconds.

Sweetness is essential but must be non-gunking. Consider:

Cooling enhances perception in disposables. But not all cooling agents behave the same under fast-heating conditions.

At CUIGUAI Flavoring, we design every flavor for device-context performance. Our flavor engineers test blends on real disposable hardware to guarantee:

Our flagship lines for disposables include:

Looking for a reliable partner to help your next disposable flavor line stand out? Contact CUIGUAI Flavoring for flavor samples and custom development support.

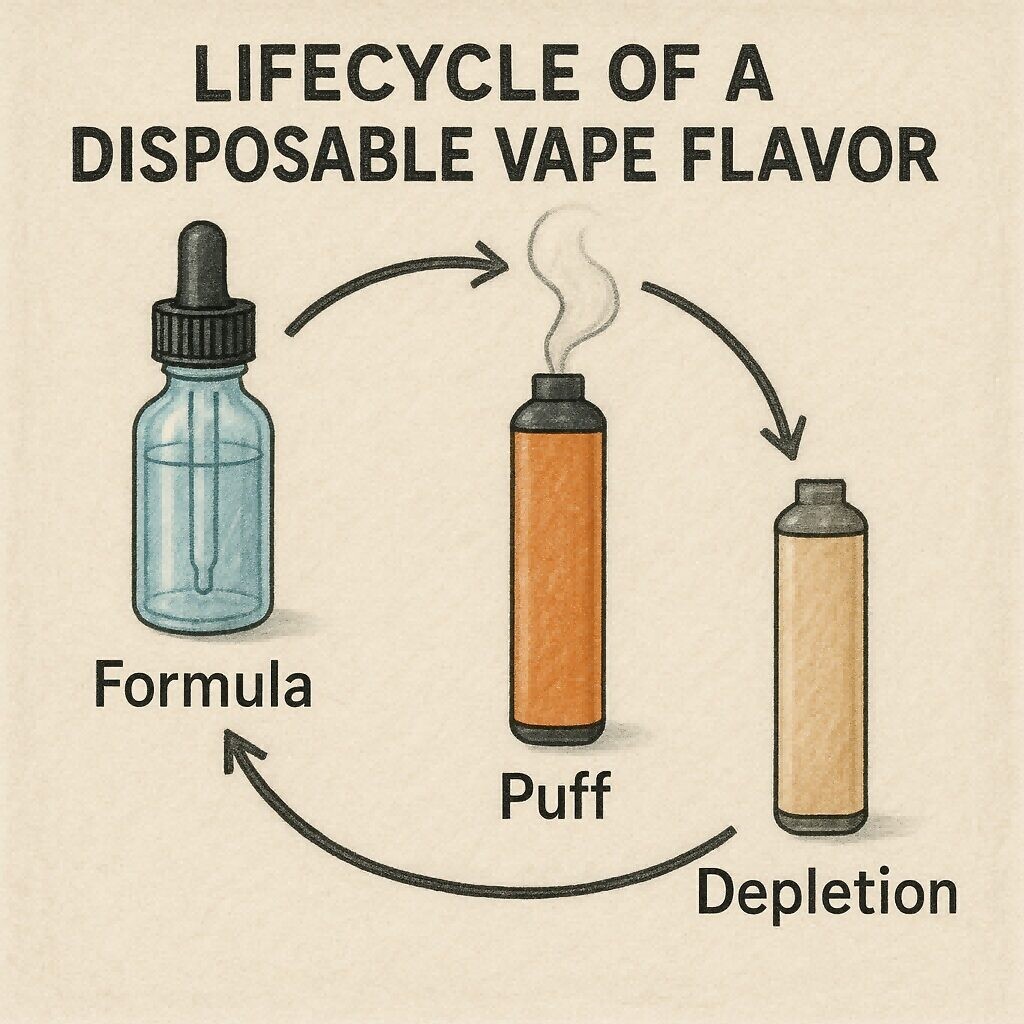

Lifecycle Of A Disposable Vape Flavor

Disposable vape flavor formulation is a discipline of precision. The limitations—volume, power, airflow, fixed heating—are not setbacks, but rather boundaries within which true innovation can thrive.

By understanding the physics of vapor delivery, the chemistry of rapid-flavor expression, and the consumer expectation of intensity without harshness, formulators can craft exceptional disposable experiences.

With fast-burn strategies, coil-aware ingredient selection, and smart layering, disposable vape flavoring becomes not just feasible—but masterful.

Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Jun 28, 2025

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy