Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Nov 24, 2025

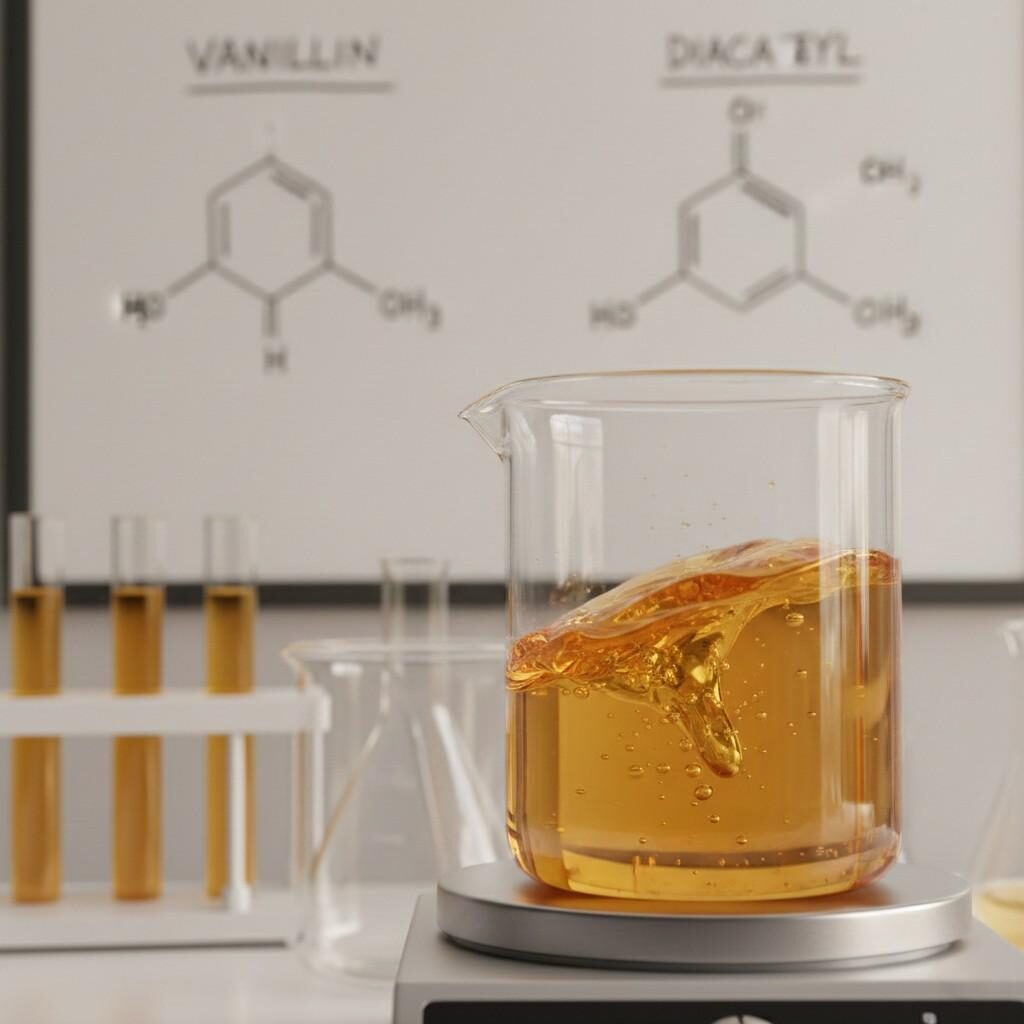

Golden Liquid Lab Scene

In the competitive landscape of electronic nicotine delivery systems (ENDS), fruit and mint profiles often dominate the market share due to their formulation simplicity. However, the “Holy Grail” of vaping—the profile that creates the most loyal, long-term consumers—remains the Dessert category, specifically Dairy.

From the nostalgic comfort of a Strawberry Milk to the sophisticated complexity of a Vanilla Custard Tobacco (VCT), dairy flavors provide a mouthfeel and satiety that fruit mono-flavors cannot replicate. Yet, for e-liquid manufacturers and flavorists, dairy is notoriously the most difficult category to master. It requires a delicate balance of organic chemistry, thermal stability physics, and regulatory compliance.

As a dedicated manufacturer of premium fragrances and flavorings for e-liquids, we understand that creating a “creamy” vape is not merely about taste; it is about engineering a sensory experience that survives high-heat vaporization. In this technical guide, we will dissect the primary challenges in developing dairy-flavored e-liquids—from the “vomit” notes of Butyric acid to the physics of coil gunk—and provide actionable solutions for your R&D team.

The elephant in the room for any dairy formulation is the history of diketones: Diacetyl (2,3-butanedione) and Acetyl Propionyl (2,3-pentanedione).

Chemically, Diacetyl is the gold standard for buttery, creamy notes. It provides that thick, coating mouthfeel that vapers crave. However, following the “popcorn lung” (bronchiolitis obliterans) concerns that emerged from industrial exposure contexts, the vaping industry has largely moved toward self-regulation to eliminate these compounds.

The challenge for formulators is that “clean” (DAAP-free) flavors often lack the inherent richness of their diketone counterparts. When you remove Diacetyl and Acetyl Propionyl, you are often left with a flavor profile that feels “thin” or lacks the heavy mid-notes that bridge the inhale and the exhale.

Most manufacturers have pivoted to Acetoin (3-hydroxy-2-butanone). While safer, Acetoin is a solid at room temperature and must be dissolved in PG or alcohol.

We recommend “stacking” Acetoin with Lactones (specifically Gamma-Decalactone and Delta-Decalactone) to restore the fatty, waxy mouthfeel without relying on prohibited diketones.

Once Diacetyl was removed from the flavorist’s palette, the industry turned to Butyric Acid to provide creamy, cheesy, and dairy notes.

Butyric acid is a short-chain fatty acid found naturally in milk and butter. However, in high concentrations—or when poorly blended—it possesses a distinct odor of vomit or rancid cheese. This is the number one complaint from consumers regarding “sour” yogurt or milk vapes.

Many mixologists find that a fresh batch of Strawberry Milk e-liquid smells fantastic, but after two weeks of steeping, it develops a sharp, acrid “baby vomit” undercurrent. This is often due to ester hydrolysis, where the fruit esters interact with the dairy acids, unmasking the raw Butyric profile.

To utilize Butyric acid effectively without the off-notes, you must employ masking agents:

A common misconception among novice formulators is the desire to use actual food ingredients (like essential oils or lipid-based extracts) to get a “real” taste.

Inhaling lipids (oils/fats) can cause lipoid pneumonia, a serious lung condition. This means conventional food-grade oil-soluble flavorings are strictly prohibited in e-liquids. However, dairy flavors in nature are inherently fat-based. Replicating the sensation of fat using only water-soluble (PG-soluble) compounds is a significant chemical hurdle.

Since we cannot use lipids, we must simulate the viscosity and lubricity of fat using safer compounds.

According to The flavor and Extract Manufacturers Association (FEMA), ensuring that flavor substances are GRAS (Generally Recognized As Safe) is the first step, but ENDS manufacturers must go further to ensure these substances are safe for inhalation, which specifically excludes lipid-based carriers [2].

Vaping Coil Comparison

Dairy flavors are notorious “coil killers.” Consumers hate changing their pods or coils every two days, yet they demand sweet, rich custard flavors.

Dairy flavors rely heavily on sugars and aldehydes (Vanillin) and ketones. When heated to 200°C+ on a metal coil, these compounds undergo the Maillard Reaction (browning) and eventually pyrolysis (burning).

The key is concentration efficiency. Instead of using 20% flavor loading with 2% Sucralose, we develop “Super Concentrates” that achieve the same organoleptic impact at 2-4% usage rates.

Have you ever developed a Cheesecake flavor that tastes amazing on day 1, but by day 30 in the bottle, it tastes like… nothing?

Dairy molecules are often heavy (low volatility), meaning they sit on the tongue longer. However, when mixed with high-VG (Vegetable Glycerin) bases, which are chemically thick and slightly sweet, the subtle dairy notes can get “buried.” Furthermore, Vanillin is reactive. It oxidizes in the presence of Nicotine, turning the e-liquid dark brown/orange. While this doesn’t necessarily spoil the flavor, it can alter the perceived freshness.

A successful dairy e-liquid needs a “Top,” “Middle,” and “Base.”

If your flavor is fading, it often lacks a “Top” note to engage the nose. We recommend adding trace amounts of bright notes (Citrus or Berry) even in pure Custards—not enough to taste the fruit, but enough to “wake up” the olfactory receptors.

Amber Vape Juice Creation

Not all dairy is created equal. Treating a “Yogurt” base the same as a “Custard” base is a recipe for failure.

For manufacturers exporting to Europe or the US, dairy flavors face scrutiny.

The Tobacco Products Directive (TPD) has strict emissions testing. While diacetyl is not explicitly banned in all member states, emission tests that show carcinogenic compounds formed upon heating will fail notification.

The FDA Pre-Market Tobacco Application (PMTA) requires full ingredient disclosure. If you are using a generic “Cream Base” from a supplier who won’t disclose the CAS numbers, your application is dead in the water.

Finally, the interaction between the e-liquid and the bottle is often overlooked.

Developing a best-selling dairy e-liquid is a feat of engineering. It requires navigating the minefield of Diketones, mastering the balance of Butyric acid, and solving the physics of coil longevity. It is not a task for amateur mixing; it demands professional-grade raw materials and deep technical support.

At our manufacturing facility, we don’t just sell flavors; we sell formulation solutions. Our “Cream & Dairy” series is the result of years of R&D, specifically designed to be DAAP-free, heat-stable, and chemically balanced to avoid off-notes. Whether you are crafting the next legendary Strawberry Custard or a niche Oat Milk Latte, our laboratory is ready to help you scale from prototype to production.

Lab Partnership Handshake

Don’t let “sour milk” notes or coil gunk ruin your brand’s reputation. Partner with a flavor manufacturer that understands the molecular science of vaping.

Contact us today for a technical consultation and free samples of our Premium Dairy Series.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.com]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy