Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Oct 27, 2025

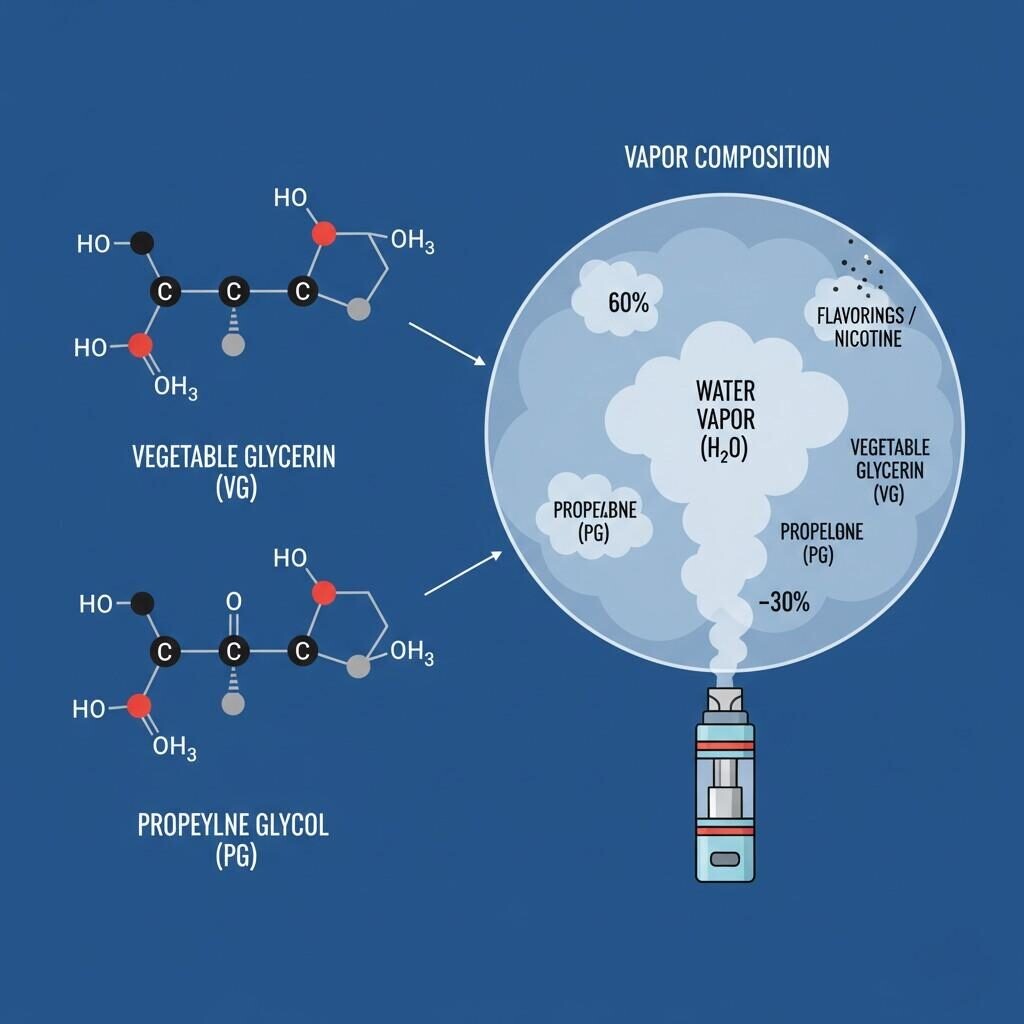

VG/PG Molecular Structure and Vapor Composition

The flavor experience of an e-liquid isn’t just about the aroma compounds or the recipe behind it. It’s equally about the base composition — specifically, the ratio of Vegetable Glycerin (VG) and Propylene Glycol (PG). These two carriers determine not only the vapor density and mouthfeel but also how flavor compounds are released, transported, and perceived during vaping.

This blog post explores the science of flavor release in different VG/PG ratios, offering a comprehensive, research-based perspective for professionals in the e-liquid manufacturing industry. Through this exploration, we will cover how physical chemistry, vaporization dynamics, sensory science, and formulation engineering converge to shape vaping experience — a crucial factor for competitive product design in a rapidly evolving market.

Propylene Glycol (PG) and Vegetable Glycerin (VG) are the foundational solvents in e-liquid formulation.

The balance between these two ingredients shapes the physical and chemical environment in which flavor compounds dissolve, vaporize, and are perceived. It’s not simply a matter of preference — it’s applied science that determines user satisfaction and product differentiation.

The VG/PG ratio affects:

A product designed for a 50/50 base will behave entirely differently from one at 70/30 VG/PG — both in vapor generation and flavor experience.

Flavor release involves several steps — dissolution, vaporization, aerosol transport, and olfactory perception. Each is influenced by the VG/PG ratio.

PG is a more polar solvent with lower viscosity. This allows volatile flavor molecules (such as esters, aldehydes, and ketones) to dissolve and evaporate efficiently. VG, in contrast, has a higher viscosity and lower volatility, which can trap some flavor compounds, slowing their release.

In essence:

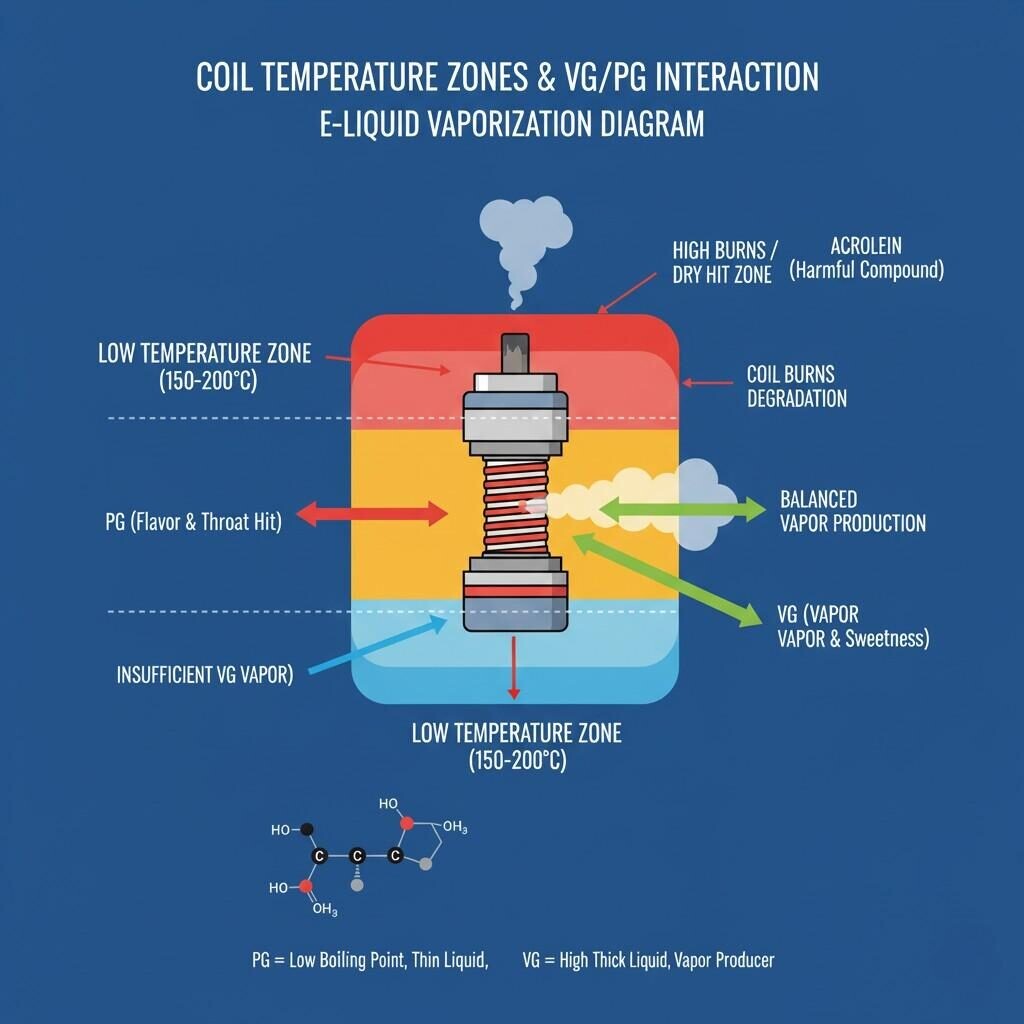

When e-liquids are heated, the base solvents undergo rapid phase changes. The vapor pressure of PG is significantly higher than VG, meaning PG-rich blends tend to carry volatile flavors into the vapor phase more efficiently. VG-rich blends require higher coil temperatures to reach similar volatilization.

As the coil heats, a two-phase system emerges — liquid and vapor. Flavor compounds partition between these phases according to their vapor pressures and solubilities in VG/PG. The proportion that enters the vapor phase defines the perceived intensity of the flavor.

Studies show that flavor molecules such as vanillin and ethyl maltol have different vaporization rates depending on solvent composition (source: Journal of Aerosol Science, Elsevier).

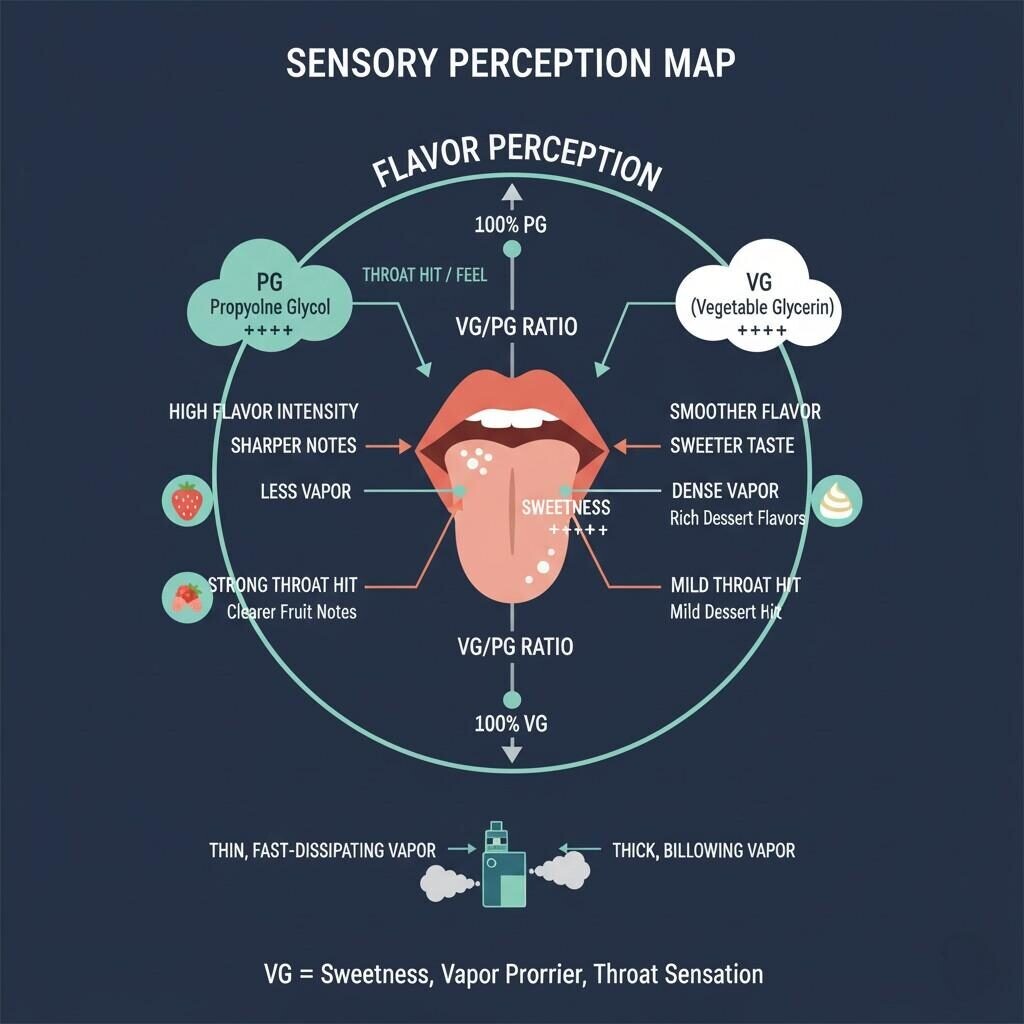

VG/PG Sensory Flavor Map

The sensory experience of vaping involves more than chemical release. It’s a multi-sensory event — taste, aroma, throat hit, and vapor texture all interact to create an impression.

Users often report that PG-rich blends deliver more intense flavors. This is consistent with the physicochemical data: higher PG content allows flavor molecules to volatilize quickly and reach the olfactory receptors more effectively.

VG’s viscosity can suppress this effect, leading to a slower, more gradual flavor delivery. However, this can also create a richer, smoother perception, which some vapers prefer for dessert or creamy flavor profiles.

VG imparts a viscous, slightly sweet texture to vapor. It also influences aerosol particle size, which affects how vapor feels in the mouth and lungs. PG provides a sharper, more immediate throat hit due to its faster evaporation rate and lower vapor density.

VG itself is slightly sweet, which can subtly influence the perception of flavor blends — enhancing dessert profiles while muting sharper fruit or menthol notes. PG, being neutral, provides a cleaner delivery that highlights high-volatility compounds.

VG’s higher viscosity limits molecular mobility, reducing the diffusion rate of aroma compounds. This leads to slower flavor release but longer retention within the aerosol phase. This can be advantageous for creamy or layered flavors, where prolonged aftertaste is desirable.

Some flavor compounds (e.g., vanillin, menthol, linalool) show preferential solubility in PG or VG depending on polarity. Manufacturers can exploit this by adjusting ratios for targeted flavor performance.

| Flavor Compound | Preferred Solvent | Effect on Release |

| Menthol | PG | Fast, sharp delivery |

| Vanillin | VG | Slow, creamy release |

| Ethyl Maltol | Balanced | Moderate, lasting sweetness |

VG-heavy formulations produce larger aerosol droplets, which carry more mass and can condense more rapidly in the mouth and lungs. PG-based aerosols are smaller, more volatile, and tend to reach deeper olfactory receptors. This difference underpins why flavor clarity varies so noticeably between ratios.

The microstructure of vapor droplets also affects light scattering (visual density) and thermal stability, influencing both appearance and taste persistence.

VG/PG Coil Interaction Diagram

The effect of VG/PG ratios isn’t static; it depends heavily on device design, including coil resistance, wicking efficiency, and airflow.

Different atomizers and coil materials also affect heat transfer, thereby influencing flavor release dynamics. Stainless steel or mesh coils, for example, often deliver more consistent temperature profiles, which can enhance flavor stability even in VG-rich blends.

VG is more prone to oxidation under heat and light, forming compounds that can alter flavor profiles over time. PG offers greater oxidative stability but may evaporate more quickly from open containers. Stabilizers or antioxidants can help maintain flavor integrity in long-term storage.

Both VG and PG are hygroscopic, meaning they absorb moisture from the environment. This can affect viscosity and flavor intensity during long-term storage. Controlled humidity packaging is essential for maintaining formulation integrity.

Both compounds are approved for use in food and pharmaceuticals, but purity and sourcing are crucial. Industrial-grade glycols must never be used in e-liquids. Always ensure compliance with relevant safety standards (source: European Chemicals Agency (ECHA)).

Formulators should consider VG/PG-dependent degradation kinetics for flavor compounds. Aldehyde-based notes (like citrus) degrade faster in VG due to oxidative susceptibility, while ester-based notes are more stable in balanced or PG-heavy systems.

Effective e-liquid formulation requires aligning physical chemistry with sensory goals. Consider these strategies:

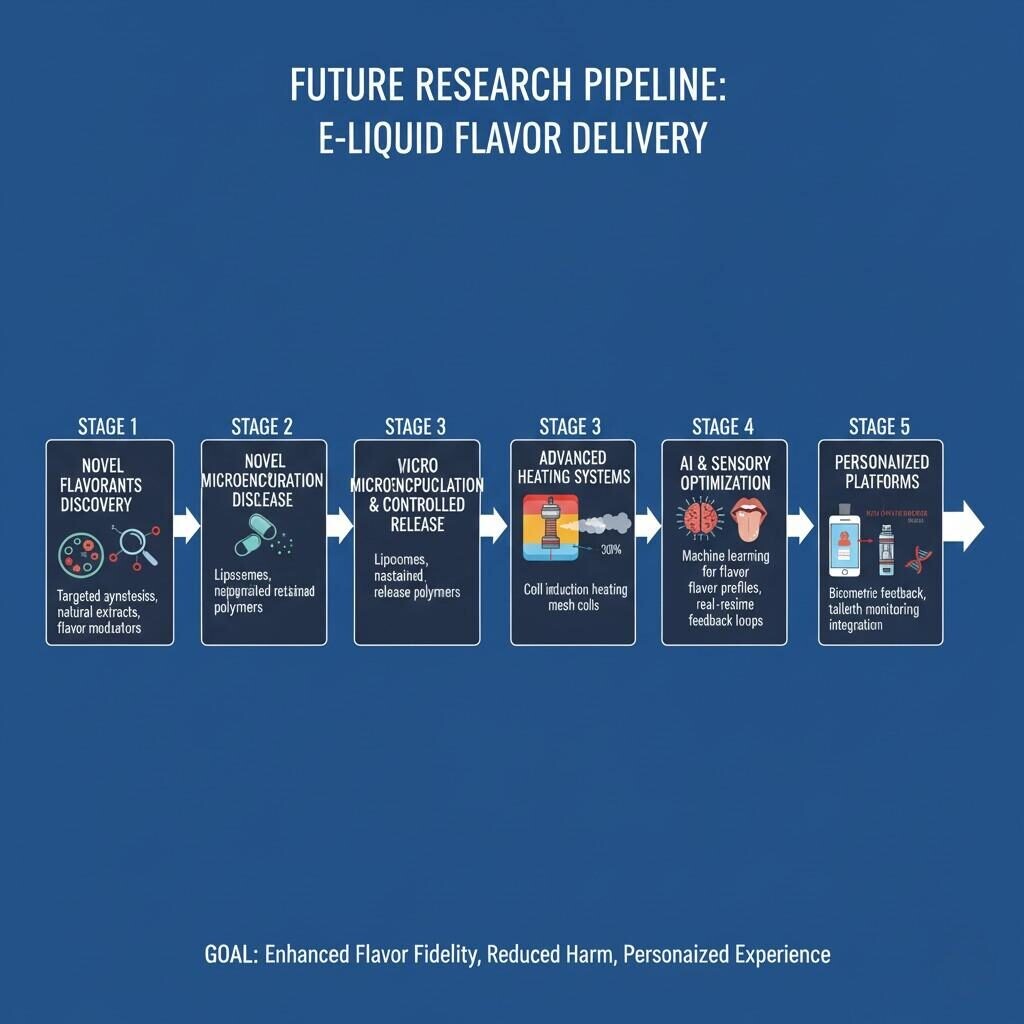

Emerging studies are focusing on microencapsulation of flavors, nanostructured carriers, and advanced solvent systems to improve flavor stability and control release kinetics in vaping applications. Additionally, innovations like hybrid glycol systems or bio-based humectants aim to maintain the performance of PG/VG while enhancing sustainability.

There’s growing interest in machine learning-driven formulation optimization, where predictive models use physicochemical data to estimate flavor release rates for different VG/PG ratios. These tools can drastically reduce R&D time for manufacturers.

E-Liquid Flavor Delivery Research Pipeline

Fruit flavors often rely on highly volatile esters such as isoamyl acetate (banana) or ethyl butyrate (pineapple). These compounds perform best in PG-dominant bases, which ensure rapid volatilization and bright top notes.

Dessert or cream profiles depend on low-volatility compounds like vanillin or ethyl maltol, which linger longer. A VG-dominant base enhances creaminess and depth. Understanding these relationships enables flavor chemists to adjust formulations not by trial and error, but through data-driven solvent pairing.

Flavor release in different VG/PG ratios is more than a formulation decision — it’s a scientific balancing act that defines how a product performs in the real world. Understanding the physical and sensory interplay between VG and PG enables manufacturers to craft e-liquids with superior stability, authenticity, and consumer satisfaction.

The future of e-liquid formulation will depend on continuous research into the relationship between solvent properties, device design, and sensory behavior — a triad that will define the next generation of vapor flavor delivery.

We offer free technical consultations and sample requests for manufacturers seeking optimized flavor solutions for specific VG/PG ratios.

Contact us today to discuss formulation strategies or request a sample set tailored to your vapor product line.

📩 [info@cuiguai.com]

📞 [+86 189 2926 7983]

🌐 Explore more at【www.cuiguai.com】

References:

1. U.S. Food and Drug Administration (FDA): Propylene Glycol Safety Information

2. U.S. National Library of Medicine: Glycerol Compound Summary

3. Journal of Aerosol Science, Elsevier: Research on vapor-phase behavior of volatile compounds

4. European Chemicals Agency (ECHA): Safety and Regulatory Guidance for Glycols

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy