Author: R&D Team, CUIGUAI Flavoring

Published by: Guangdong Unique Flavor Co., Ltd.

Last Updated: Dec 02, 2025

E-Liquid Precision Dosage

In the competitive world of e-liquid manufacturing, the difference between a market-leading product and a stagnant SKU often comes down to a fraction of a percentage point in formulation. For our clients—whether they are large-scale OEM manufacturers, boutique mixologists, or wholesale distributors—understanding the delicate science of flavor dosage is paramount. There is a prevailing myth in the industry, often driven by novice formulators, that “more flavor equals better taste.” This is a fundamental misunderstanding of olfactory science and chemical volatility.

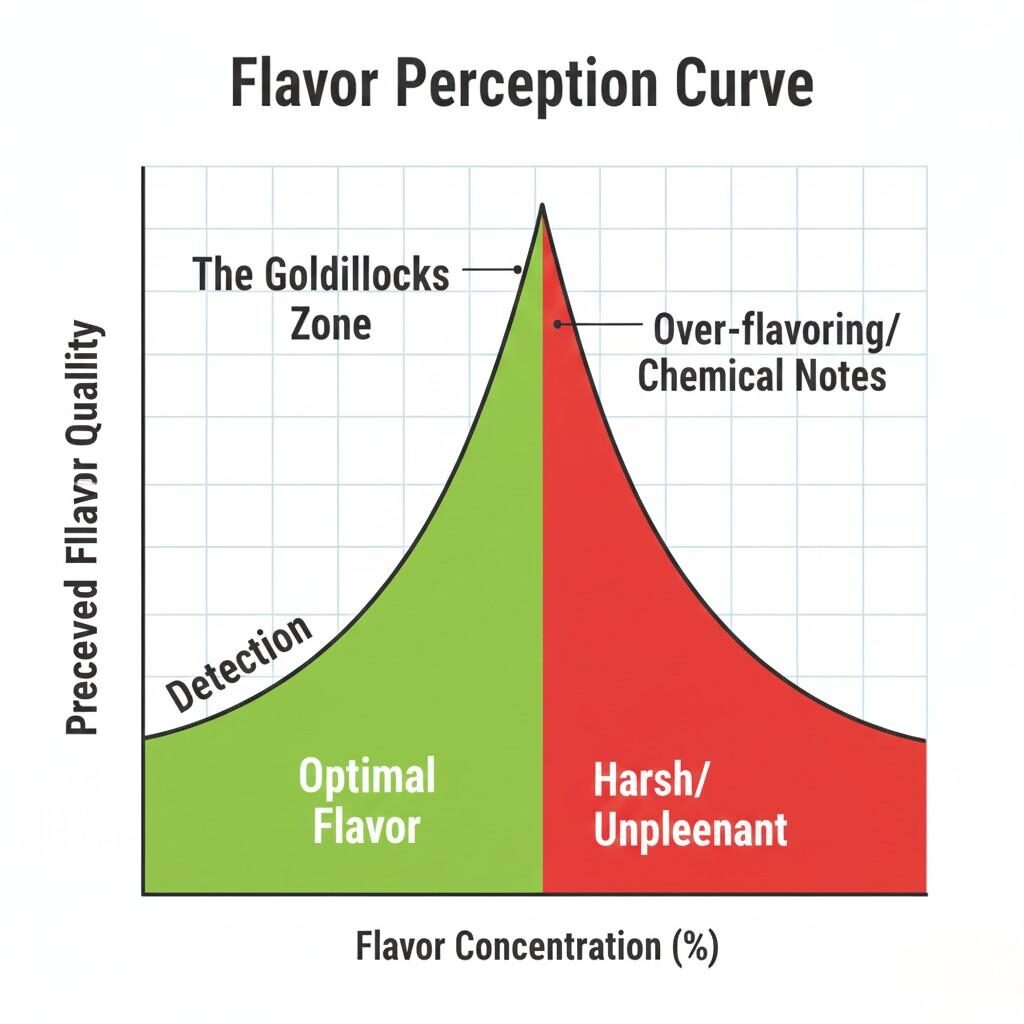

The reality is that flavor perception follows a non-linear curve. As a manufacturer of premium flavorings, we view it as our responsibility to educate our partners not just on what flavors to use, but how to use them to achieve the “Goldilocks Zone”—the precise dosage where flavor fidelity is maximized, chemical off-notes are nonexistent, and manufacturing costs are optimized. This concept is technically known as the Flavor Dosage Threshold.

This article serves as a comprehensive technical guide to understanding, testing, and mastering flavor thresholds. We will explore the physiological mechanics of taste and smell, the impact of carrier bases (PG/VG), the phenomenon of olfactory fatigue, and the economic implications of precision dosing.

To control a variable, one must first define it. In the context of electronic liquid formulation, the flavor dosage threshold is not a single point, but rather a spectrum consisting of three distinct stages. Understanding these stages allows formulators to pinpoint exactly where their product sits on the sensory curve.

The detection threshold is the lowest concentration at which a sensory panel can detect something is different from the neutral base (pure PG/VG and nicotine), but cannot yet identify what the specific flavor is.

This is the concentration at which the flavor becomes identifiable. The consumer can taste “strawberry” or “vanilla custard.”

This is the critical ceiling. It is the concentration at which adding more flavor concentrate does not increase the perceived intensity of the positive flavor notes.

To understand why adding more flavoring can actually ruin a product, we must look at human biology. Flavor is not merely “taste” (which happens on the tongue); it is a complex interaction between gustatory (taste) and olfactory (smell) systems.

The human nose is an incredibly sensitive instrument, but it is designed for adaptation. When olfactory receptors are bombarded with a constant, high-intensity signal (an over-flavored e-liquid), the brain engages a mechanism known as sensory adaptation or olfactory fatigue. This is commonly referred to in our industry as “Vaper’s Tongue.”

According to research available through the National Center for Biotechnology Information (NCBI), the olfactory system adapts to continuous stimuli to prevent the brain from being overwhelmed. If a manufacturer overloads a juice with 20% flavoring when 12% was the saturation point, the user’s receptors shut down faster. The result? The user claims the juice has “no flavor” after only a few puffs. Ironically, the solution to “no flavor” in this context is often to reduce the dosage, not increase it.

Vaping is unique because flavor is perceived largely through retronasal olfaction—exhaling the vapor through the nose. High concentrations of volatiles can cause irritation to the sensitive mucous membranes in the nasal passage. This physical irritation (stinging or tingling) distracts the brain from the flavor profile, registering the sensation as “harshness” rather than “taste.”

A “one-size-fits-all” percentage does not exist in professional manufacturing. A 5% dosage of a Super Concentrate (SC) might be overwhelming, while a 5% dosage of a standard flavor might be undetectable. Furthermore, the environment in which the flavor exists changes the threshold.

This is the most critical variable for our clients to adjust for.

Flavor molecules are volatile; they evaporate at different temperatures.

Flavor Perception Curve Infographic

Why do we advise our clients to be so rigorous about finding the lowest effective dosage? The risks of over-flavoring extend beyond just “bad taste.”

Many flavor concentrates contain ethyl alcohol or triacetin as carriers. At high dosages, these carriers manifest as a harsh throat hit or a “boozy” aftertaste. Furthermore, specific flavor volatiles, such as those found in cherry or floral profiles, can taste like soap or medicine if the dosage exceeds the saturation point by even a small margin.

Sweeteners (Sucralose, Ethyl Maltol) and heavier natural extracts do not vaporize as cleanly as PG/VG. They leave carbon residue on the heating element. An over-flavored liquid will destroy a client’s coil in one or two days, whereas a properly dosed liquid could last a week. In the consumer market, “coil killer” juices gain a bad reputation quickly.

Flavor concentrates are typically suspended in PG. Adding 25% flavoring to a mix meant to be “Max VG” effectively dilutes the VG content, turning a thick liquid into a runny one. This causes leaking issues in modern tanks. Mastering dosage allows manufacturers to maintain the structural integrity of the e-liquid’s viscosity.

For our B2B clients, this is perhaps the most persuasive argument for precision dosing. Flavoring is often the most expensive component of an e-liquid bottle, costing significantly more per milliliter than PG, VG, or Nicotine.

Let’s look at a hypothetical scenario for a manufacturer producing 100,000 bottles (60ml each) per month.

The Math:

This demonstrates that understanding dosage thresholds is not just an artistic endeavor; it is a vital strategy for margin protection.

We recommend our clients use a “Titration” or “Stepping” method to determine the optimal dosage for any new flavor profile. Do not rely on the “recommended percentage” on the bottle as a rule; treat it as a starting guideline.

Prepare a large batch of your target base (e.g., 70VG/30PG) with your target nicotine level. Crucial Note: Nicotine affects flavor perception (adding pepperiness or harshness). You must test with nicotine present to get an accurate result.

Create 5 small test batches (10ml each) with increasing increments of flavoring.

Time is an ingredient. Freshly mixed liquid has not homogenized. Volatiles are still “raw.” We recommend a minimum 48-hour steep (or ultrasonic homogenization) before testing. For custards and tobaccos, a 2-week steep is required for accurate threshold testing.

Do not label the bottles with percentages. Label them A, B, C, D, E. Have a panel of at least 3 testers vape the samples, starting from the lowest concentration to the highest (to prevent olfactory fatigue from setting in early).

Tester Goal:Identify the point where flavor intensity stops increasing and merely becomes “heavy.”

Clean-Room Liquid Inspection

As a responsible manufacturer, we align our dosage recommendations with global safety standards. Over-flavoring isn’t just an economic issue; it is a compliance issue.

The Flavor and Extract Manufacturers Association (FEMA) establishes the GRAS (Generally Recognized As Safe) status for flavor ingredients. However, GRAS status is typically calculated based on food ingestion, not inhalation. Because of this, staying within reasonable dosage limits is a precautionary necessity. High concentrations of certain compounds (like cinnamaldehyde or vanillin) can be sensitizers at high levels. Adhering to the dosage threshold ensures the consumer is exposed to the minimum amount of volatiles necessary to achieve the desired taste.

In the United States, the FDA monitors e-liquid manufacturing standards. While they do not currently mandate specific flavor percentages, they rigorously enforce Good Manufacturing Practices (GMP). A product that is unstable due to over-flavoring (separation of layers) can be flagged as adulterated. Similarly, under the European Union’s TPD (Tobacco Products Directive), toxicology reports are required. Keeping dosages optimized reduces the total load of carbonyls produced during vaporization, leading to cleaner toxicology reports.

For further reading on the regulatory landscape of manufacturing standards, the FDA provides guidance on “Premarket Tobacco Product Applications and Recordkeeping Requirements” which indirectly highlights the need for precise formulation consistency.

Once a client understands the threshold of a single flavor, the next challenge is mixing. This is where the concept of the “Symphony” comes in.

If you have a Strawberry (Threshold 10%) and a Cream (Threshold 8%), you cannot simply mix them at 10% + 8% = 18%. This will likely result in a muted, muddy mix. When combining flavors, the Total Flavor Percentage often needs to be lower than the sum of its parts. This is because different molecules compete for the same olfactory receptors.

By respecting the threshold of the mix rather than just the ingredients, you create complex, layered profiles that remain crisp and clean.

We are observing a massive shift in the global vape market. In the early days of vaping (2012-2015), “premium” juices were often incredibly rich, dark, and over-flavored (sometimes 25-30% flavor). Today, the trend is shifting toward “Clean Mixing.”

According to market analysis reports by Grand View Research, the global e-liquid market is projected to focus heavily on quality assurance and product consistency in the coming decade. Manufacturers who can scientifically justify their formulations will win consumer trust.

The “Flavor Dosage Threshold” is not a limitation; it is a tool. It is the compass that guides a manufacturer away from waste and inconsistency and toward quality and profitability.

At our company, we don’t just sell flavorings; we sell the expertise to use them effectively. We understand that your success depends on the reception of your final product. By respecting the science of the threshold—testing for it, adhering to it, and scaling it correctly—you ensure that your e-liquids are safe, delicious, and economically viable.

Don’t let your profits evaporate with wasted concentrate. Let’s formulate the future together, one precise drop at a time.

Premium E-Liquid Lineup

Are you ready to optimize your e-liquid formulations for maximum flavor and profitability?

We offer free technical consultations and sample testing kits to help you find the perfect dosage for your next bestseller. Do not guess—measure.

📧 Email: [info@cuiguai.com]

🌐 Website: [www.cuiguai.com]

📱 WhatsApp: [+86 189 2926 7983]

☎ Phone: [+86 0769 8838 0789]

Contact us today to schedule your formulation review!

The business scope includes licensed projects: food additive production. General projects: sales of food additives; manufacturing of daily chemical products; sales of daily chemical products; technical services, technology development, technical consultation, technology exchange, technology transfer, and technology promotion; biological feed research and development; industrial enzyme preparation research and development; cosmetics wholesale; domestic trading agency; sales of sanitary products and disposable medical supplies; retail of kitchenware, sanitary ware and daily sundries; sales of daily necessities; food sales (only sales of pre-packaged food).

Copyright ©Guangdong Unique Flavor Co., Ltd.All Rights Reserved. Privacy Policy